Excessive Vibration Occurred During OHT Rail Car Operation?

Case | Excessive Vibration Occurred During OHT Rail Car Operation?OHT plays a critical role in wafer transportation. Abnormal vibrations and insufficient transport stability can lead to product quality issues. How can such issues be predicted in advance?

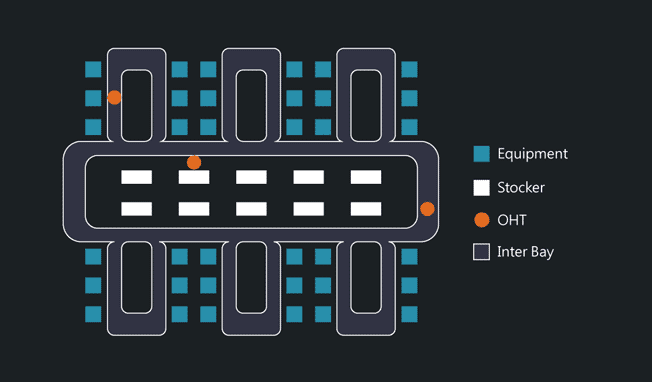

OHT Overhead Transport System

The primary object transported by OHT is wafers. With the advancement of the semiconductor industry, cleanroom automation has improved significantly. In highly regulated environments, unmanned automated transport systems like OHT are widely adopted.

OHT functions like a transportation network in a small city, ensuring smooth movement within the facility while adhering to designated paths and schedules.

OHT is also known by various names such as overhead transport vehicle, crane system, and aerial transport system. The primary "passenger" of OHT is the wafer, and the vehicles follow predefined routes. Encounters with other OHT vehicles are common, and any instability in traffic speed or movement could indicate excessive vibration, anomalies, or collisions. Severe cases can result in wafer damage or system disruptions.

Monitoring Overview

IIoT Unlimited: Industrial IoT

OHT is an unmanned transport vehicle, and ensuring transportation quality is crucial to preventing unnecessary losses and enhancing semiconductor production efficiency and reliability.

It is essential to equip OHT vehicles with monitoring instruments or sensors. Through a central monitoring dashboard, real-time monitoring, alerts, and maintenance actions such as component replacements can be carried out to ensure smooth transport operations.

Measurement Status

OHT Rail Car Vibration Quality Monitoring

1. Detection Target: Excessive vibration during rail car operation

2. Confirm if the abnormal vibration is caused by rail car motion

3. Perform self-diagnosis to verify track health and ensure the issue originates from the rail car

4. Issue alerts for abnormal vibration of individual rail cars

Scout Mode:

1. Detection Target: Abnormal track conditions

2. Usage Scenario: Full track inspection after periodic maintenance, with monitoring modules tracking OHT vibration conditions in real-time

(prolonged excessive vibration and sudden vibration spikes are considered alert events).

• The module simultaneously synchronizes position information with the OHT.

• If an alert event occurs (vibration signal exceeds internal threshold), an over-limit alert is triggered.

To the Main System:

• Alert Information: Alert notifications, real-time vibration data (g/RMS), current OHT position information.

• Alerts and data are primarily transmitted via WiFi.

• In case of WiFi signal failure, a secondary backup (low-frequency transmission) ensures reliable alert delivery.

• If vehicle communication is lost, the backup system can still report excessive vibration events with OHT identification but without location details.

Measurement Conclusion

By installing sensors on the OHT vehicle, it is possible to detect abnormal vibrations, assess track conditions, and track real-time vehicle positions. When an anomaly occurs, immediate alerts can be issued.

Gain control of production lines and perform real-time anomaly detection. Utilizing Industrial IoT solutions for continuous monitoring ensures unexpected failures are avoided.

IIoT Solutions