Rotating Equipment Monitoring

Technical Concept|Rotating Equipment MonitoringMost industrial equipment contains motors, which drive mechanical operations. Therefore, factories are filled with motors, pumps, compressors, air conditioning units, etc. If the rotor status can be monitored, 60-70% of equipment issues can be identified.

Why is Rotor Quality Monitoring Necessary? Reasons for Implementation

Factories are equipped with numerous automation devices, most of which contain motors. The rotor’s condition is a key factor in determining whether the equipment is functioning properly. By monitoring the rotor, we can assess the health of the motor and thereby identify 60-70% of equipment issues. In smart manufacturing, automated equipment replaces manual labor, but machines themselves do not communicate their condition. Even brand-new equipment is not flawless and generates reciprocating forces and vibrations during operation. By measuring the vibration signals of the equipment, meaningful insights can be obtained.

How to Implement

1. Apply ISO Standards

All rotor quality monitoring systems developed by GoodTech include built-in ISO 10816 / 20816 standards. The operation is simple and requires no training. Issues can be resolved immediately without waiting for maintenance personnel. The software uses indicator lights to display equipment status, allowing even personnel without a vibration measurement background to quickly assess results.

Implementing Rule Base

This step involves importing Rule Base based on the power rating of the rotating equipment (motor nameplate) in the factory. At this stage, the primary focus is on setting up ISO 10816 management, ensuring that once all equipment specifications in the factory are configured, complete visualization of factory-wide equipment quality can be achieved. The software categorizes all equipment into four statuses using indicator lights: Excellent, Normal, Warning, and Danger.

Maintenance & Inspection Guidelines

Equipment in Excellent or Normal condition can continue operation without special arrangements. Equipment in Warning status should be scheduled for the next maintenance cycle. Equipment in Danger status indicates an imminent risk of shutdown and requires immediate replacement or repair.

How to Implement

2. Feature Accumulation & Anomaly Analysis

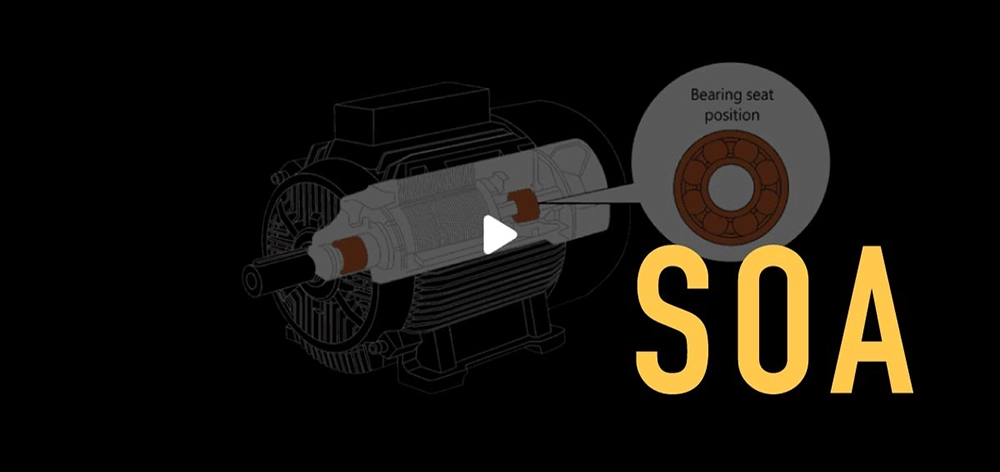

During routine management processes, multiple characteristic values collected by sensors are stored in the database. Special SOA (Spectrum Overall Value) algorithms amplify these characteristic values, enabling early detection of abnormal signals. For many types of mechanical equipment, vibration measurements provide numerical data that reflect equipment status. Typically, abnormalities can be easily identified in a frequency spectrum chart. By quantifying spectral vibration data, we can derive a total intensity value known as SOA, which is an unlimited quantification of spectral data. By monitoring SOA variations, users can easily detect changes in vibration characteristics. Additionally, at this stage, users can set customized thresholds for specific characteristics of interest or for features displaying obvious trends.

A More Effective SOA Algorithm

GoodTech’s SOA values differ from traditional OA values available on the market. SOA (Spectrum Overall Value) distinguishes effective signals from environmental system noise. The special SOA algorithm suppresses noise to achieve clearer and more efficient resolution, making its early fault detection capability four times more effective than conventional market algorithms.

Rotating Equipment Anomaly Detection

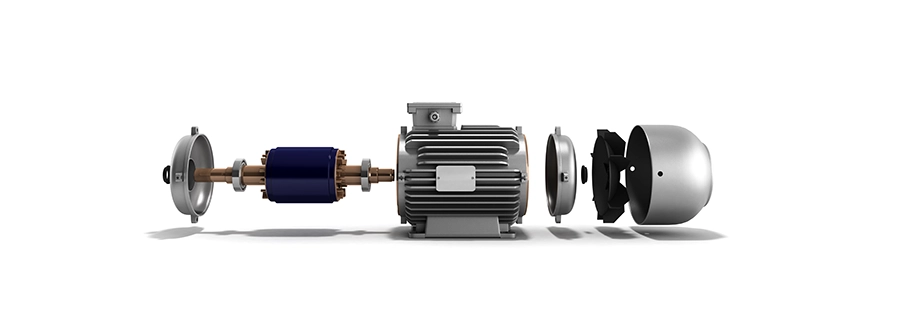

Detection of various motor rotor vibration anomalies. Vibration data serves as an early indicator and can effectively reveal issues such as insufficient lubrication, bearing friction, or initial shaft bending through vibration spectrum analysis or vibration values.

Rotor Motor Equipment DetectionIndustrial Equipment Anomaly Detection

A vibration measurement and analysis instrument designed for high-end equipment. It features spectrum analysis, time-frequency analysis, vibration transmissibility, and dynamic analysis. On-site measurement and troubleshooting can be performed directly next to the machinery.

Measure Dynamic Signal Changes of Components

Implementation Method

3. AI Prediction & Optimization

The AI training software of Gude Technology automatically trains monitoring models based on built-in specifications.

(As data accumulates, the software will automatically retrain and optimize the model at the set time intervals).

This AI prediction model is optimized based on the initial Rule Base management principles, so

the AI display follows the user-defined prediction period.

For example, if the user specifies "30-day prediction," the software will display trends for the next 30 days.

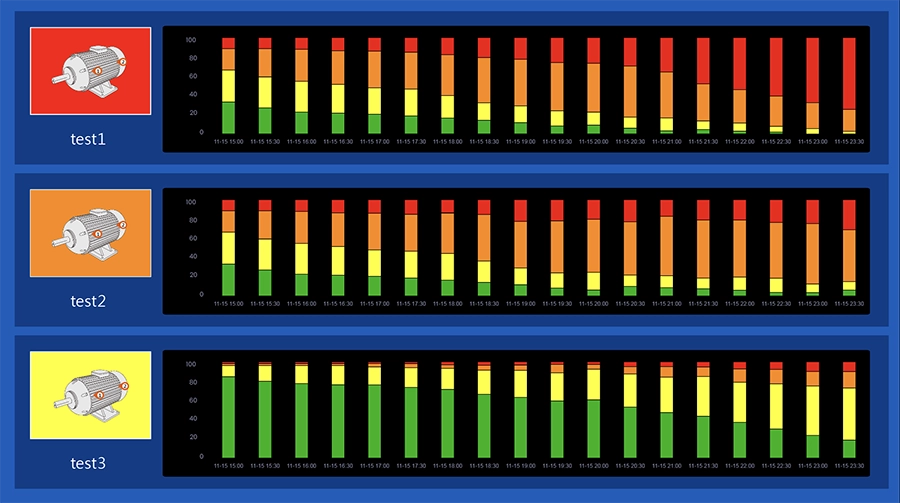

The background is color-coded into four levels: **Excellent (Green), Normal (Yellow), Warning (Orange), and Danger (Red)**,

making it easy for users to visually interpret the equipment status.

Implementation Method

4. Risk-Based Maintenance Scheduling

**What is risk-based maintenance management?

A large number of machines should not rely solely on a single maintenance strategy.

Do you often feel overwhelmed with too many machines to manage?

Are you struggling to decide which equipment needs priority maintenance?

How can you effectively plan maintenance schedules to enhance efficiency?

By implementing risk-based classification, along with corresponding detection threshold levels,

maintenance plans can be structured based on the importance of the equipment.

This approach enables better control over the health status of critical machines** and significantly improves

the efficiency of the maintenance workflow.

Recommended Equipment Classification Indicators

Production Capacity

Correlation

Safety

Correlation

Maintenance

Frequency

Maintenance

Cost

Backup Equipment

Feasibility

Spare Parts

Replacement Difficulty

Implementation of Standardized Classification

Applying Different Management Standards Based on Equipment Levels

Different control standards are applied depending on the priority level of the equipment.

Each standard displays results using indicator lights:

a green light indicates compliance, while a red light indicates non-compliance.

Under any control standard, if a single red light appears, it means the equipment is abnormal, and an immediate shutdown for maintenance is recommended.

Support

Other Rotor-Related Cases