Identify 60-70% of Key Equipment Issues

Why is it necessary?

The Motor is the Heart of All Equipment

Factories are filled with automated equipment, and when a motor fails or breaks down, it can lead to equipment or system shutdowns.

Therefore, motors are a crucial core component of equipment, and by monitoring the health of a motor's rotor, you can identify 60-70% of key equipment issues.

To ensure the proper operation of all manufacturing process equipment, immediate motor inspections should be scheduled.

Identifying early signs of failure helps prevent unexpected shutdowns and provides reliable data to implement predictive maintenance in advance.

Why is it necessary?

Vibration data is an early indicator of equipment failure

There are various methods for motor inspection (as shown in the right image). Traditionally, users have relied on monitoring current and temperature to assess motor health.

However, current and temperature are lagging maintenance indicators, meaning that by the time shaft friction or lubrication deficiency has occurred,

these parameters have already increased—potentially leading to equipment shutdown or failure.

In contrast, vibration data serves as an early indicator, allowing detection of lubrication issues, bearing friction, or shaft misalignment in the initial stages

by analyzing vibration spectra or vibration levels.

Problem Detection

Prevent Issues in Your Factory!

Early Wear of Mechanical Components

Production Line Stoppage and Delays

Lower Motor Operating Efficiency

Unexplained Abnormalities

Feature Description

Digital Measurement for Various Rotating Machinery Equipment

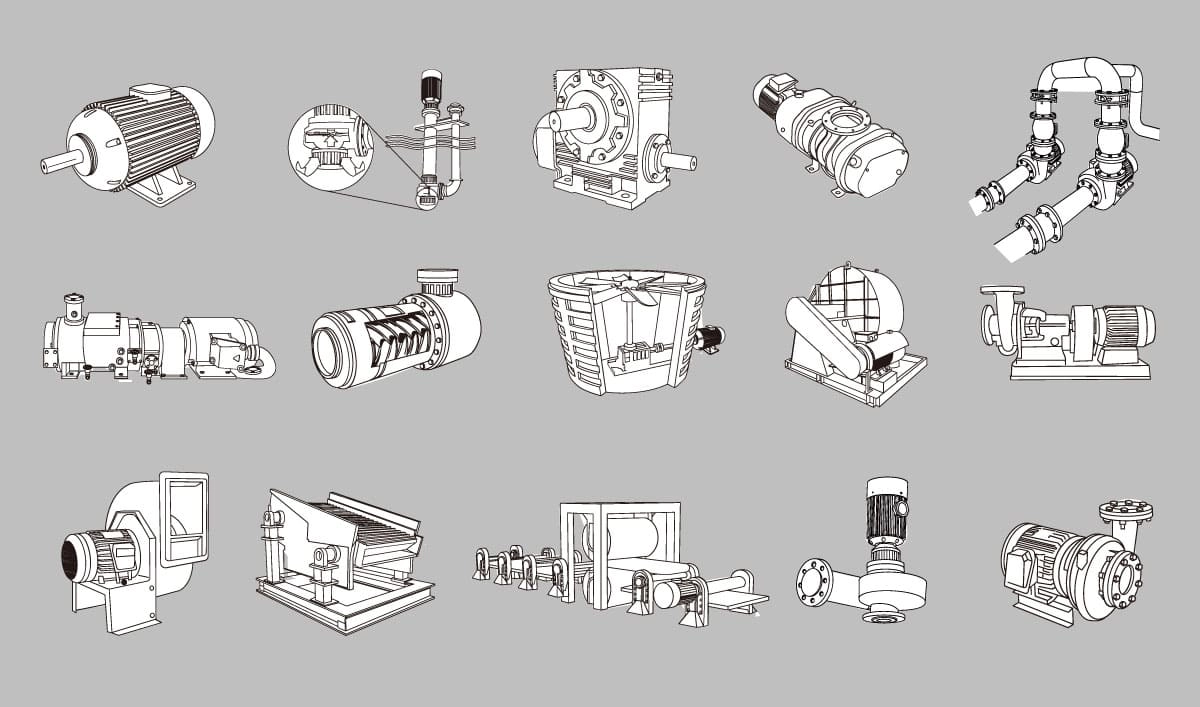

The SMS-RC Rotating Machinery Vibration Detection Analyzer is a portable measurement device, designed for users to carry easily. With just one unit, it can be used to measure and inspect all types of motors, pumps, and rotor equipment across different brands and models.

By transforming measurement methods into quantifiable data, it eliminates the reliance on traditional technicians' experience-based assessments. This device is also ideal for factories that cannot install a monitoring system and require periodic human inspections of equipment conditions.

Feature Description

Lowering Technical Barriers and Simplifying Setup

The SMS-RC Rotating Machinery Vibration Detection Analyzer integrates proprietary algorithms with ISO standards, bridging the gap between experienced experts and general technicians. Unlike traditional complex parameter settings, users simply input the motor speed found on the motor's nameplate and select the corresponding standard in the software to start measurement.

With its user-friendly operation, no training is required—users can start using it immediately. There is no need to wait for maintenance personnel, as the software provides status indicators via signal lights. Even technicians without a background in vibration measurement can quickly interpret the results.

Feature Description

Minimize Over-Maintenance / Maximize Re-Inspection Mechanisms

Currently, many companies rely on in-house expertise and external consultants for condition-based monitoring and maintenance.

Have you ever wondered if a machine is being over-maintained or if it has not been maintained at all?

Do certain machines keep coming back for repairs, making you question whether they were actually fixed?

By using the SMS-RC Rotating Machinery Vibration Detection Analyzer, you can re-check the condition of the equipment that has been returned from the repair factory. It also allows you to plan the next maintenance appointment efficiently.

Feature Description

Easy to Use Even Without Measurement Experience

The SMS-RC Rotating Machinery Vibration Detection Analyzer features simple software operation, making it easy to use even for those without prior measurement experience. Not sure where to begin measuring?

The motor rotor inspection system provides suggested measurement points for motors, pumps, cooling towers, and more. You can start measuring right away by following the recommended measurement points in the software.

Feature Description

Lightweight and Portable, Ready to Measure Instantly

The SMS-RC Rotating Machinery Vibration Detection Analyzer is easy to install. Simply attach the vibration sensor (accelerometer) to the bearing end using magnetic absorption or screws, select the appropriate ISO standard for the equipment being measured, and start measuring immediately.

This lightweight and portable model is ideal for factory maintenance and equipment inspection personnel to quickly check machine conditions on-site. The included industrial tablet is rated IP65 for waterproof and dustproof protection, and its battery lasts up to 8 hours of continuous operation.

4 Major Functions Combined into One

Rotor Quality

Compatible with various rotating equipment, built-in ISO 10816, 20816, and 2372 standards.

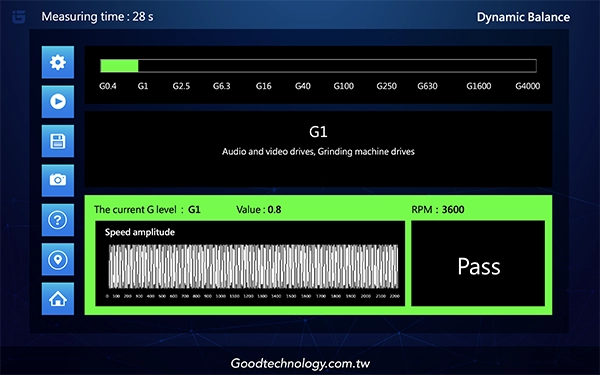

Dynamic Balance

Built-in ISO1940, simply select the equipment’s G grade for balancing evaluation.

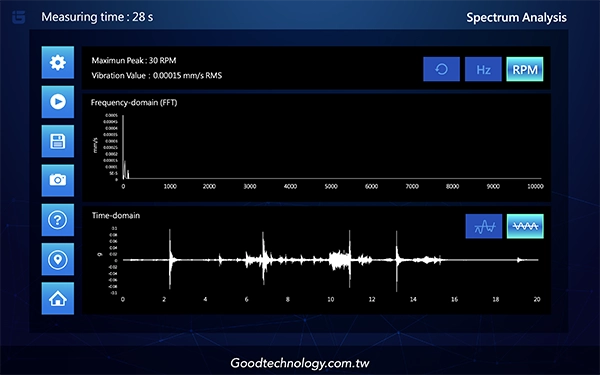

Spectrum Analysis

Analyzes vibration frequency and amplitude distribution to detect misalignment, shaft friction, and other fault characteristics.

Vibration Meter

Built-in precision vibration meter with HPF functionality, supports screenshot recording at any time.

Feature Description

UI Function Interface

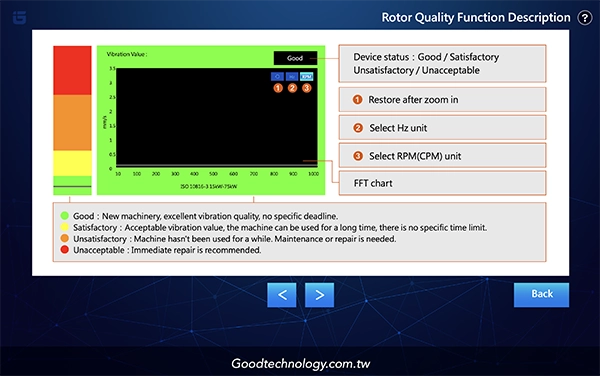

Rotor Quality

SMS-RC Rotating Machinery Vibration Analyzer is equipped with built-in ISO 10816 and ISO 2372 standards, vibration value display, and mechanical damage frequency spectrum characteristic maps.

Additionally, Solid Tech has taken the lead in the market by incorporating the latest ISO 20816 standard, allowing users to comprehensively manage motor rotor components.

Based on ISO vibration standards, the system defines equipment conditions. Users do not need to refer to tables; they can quickly determine the status of motor rotors through the intuitive UI light indicators.

The system classifies conditions into four levels: "Excellent," "Normal," "Warning," and "Danger," enabling users to resolve issues instantly without waiting for an inspection technician.

Built-in Spectrum Analysis & Dynamic Balancing

SMS-RC Rotating Machinery Vibration Analyzer is equipped with spectrum analysis functionality, supporting various physical units and linear conversions.

Users can leverage this function to analyze frequency components in complex vibration sources, facilitating failure analysis and equipment environment adjustments.

The built-in ISO1940 dynamic balancing standard allows users to select the equipment type and input the current operating speed to instantly determine whether the dynamic balance level meets the standard.

Built-in Vibration Meter

SMS-RC Rotating Machinery Vibration Analyzer is equipped with HPF (High-Pass Filter) and LPF (Low-Pass Filter) customizable filtering functions, making it suitable for measuring bearing vibrations.

It also features multiple averaging and maximum vibration value locking functions, allowing users to switch between different measurement units, quickly check vibration values, and take screenshots.

Applications

Fields and Scope

Manual Inspection Equipment

For maintenance and inspection personnel, replacing subjective judgment with data-driven verification.

Pre-shipment Repair Quality

Ideal for factory maintenance contractors, ensuring periodic equipment inspections.

Repair Report Creation

Provides valid data for users to easily generate reports and support repair decisions.

Replacement Parts Verification

Allows customers to verify the quality of motors and rotors after repair or replacement.

Parameter Change Reference

Raw data can be used to adjust feed rates, rotational speeds, and other parameters.

Pre-shipment Inspection

Ensures quality verification of motor equipment before acceptance and final shipment.

Applications

Target Users

Factory Maintenance Department:

For factory equipment maintenance and inspection personnel. Replaces subjective judgment with data-based verification.

Facility/Equipment Engineers:

Helps confirm equipment condition and provides data-based evidence for repair requests.

Outsourced Maintenance Providers:

For companies managing factory equipment maintenance contracts, offering regular inspection and service.

Equipment Manufacturers:

Identifies equipment issues during scheduled maintenance and assists customers with repair or replacement needs while keeping records.

Repair Service Providers:

Provides evidence for equipment repairs or offers regular inspection services for customers.

Applications

Target Equipment

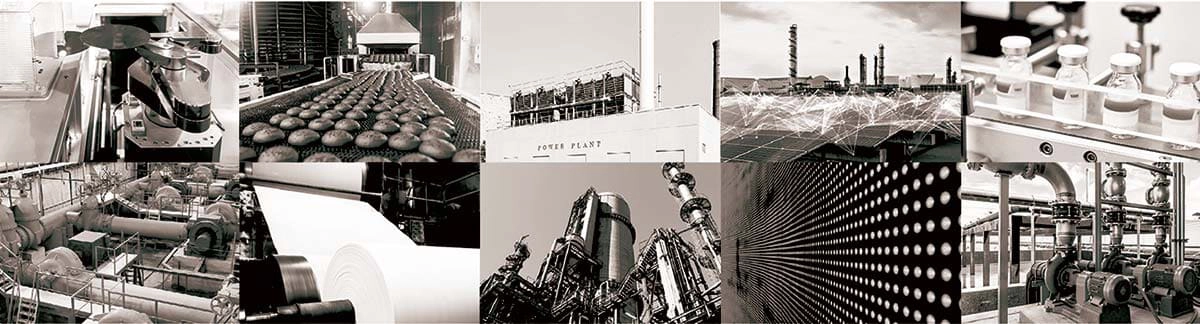

Application Fields:

Semiconductor industry, petrochemical plants, food factories, pharmaceutical plants, paper mills, panel factories, LED factories, power plants, pumping stations, wastewater treatment plants, manufacturing, equipment manufacturers, and maintenance service providers.

Target Equipment:

Pumps and suction/water equipment: vacuum pumps, oil pumps, sewage pumps, etc.

Production machinery: machine tool spindles, cutting machines, etc.

Air compressors: screw-type, centrifugal, reciprocating compressors, etc.

Others: cooling towers, exhaust fans, air handling units, etc.

Specifications

GoodTech Dedicated Tablet

Specifications

SMS-RC Kit

Vibration signal transmission cable (2 meters) × 1

USB DAQ connection cable × 1

Vibration sensor (100 mV/g) × 1

Sensor magnetic base × 1

Video

How to Determine Motor Quality?

Vibration is everywhere.

Any moving or rotating mechanism inevitably has vibration issues. Vibration is a faithful indicator of mechanical operation quality. By analyzing vibration measurement signals, we can evaluate and monitor rotor health conditions.

Traditionally, operators relied on experience, intuition, and auditory judgment to assess motor conditions. However, with the portable SMS-RC Rotating Machinery Vibration Analyzer, maintenance personnel can now obtain real-time, accurate data to determine motor conditions effectively.

It is suitable for measuring various types of motors, including pumps, motors, fans, and conveyor transmission mechanisms.

Support

Other Rotor-Related Equipment