Maintenance Speed Increased by 7x, Reduce Annual Maintenance Costs

FAQ|Maintenance Speed Increased by 7x, Reduce Annual Maintenance CostsPerform preventive maintenance before equipment failures occur to prevent machine malfunctions and mechanical damage. Preventive maintenance includes testing, measurement, adjustments, part replacement, and cleaning.

Why Implement It?

Are You Wasting Money on Maintenance?

Preventive maintenance before failures occur

Are you spending unnecessary money on maintenance? Should equipment that still appears usable be discarded?

Predictive Maintenance (PDM) is a method of maintaining equipment in optimal operating condition through systematic detection,

monitoring, and correction of early-stage anomalies. This process helps detect issues before they escalate into major failures,

preventing mechanical breakdowns. Preventive maintenance includes testing, measurement, adjustments, part replacement, and cleaning.

How It Works

Proactive Maintenance and Variable Control

Plan maintenance at the right time

No machine is perfect. All machines generate vibrations during operation, and these vibrations

provide a basis for quality control. However, all machines deteriorate over time due to human operation or natural wear.

While it is impossible to completely prevent equipment degradation,

early detection and measurement can extend machine lifespan and maintain operational quality.

Planning maintenance at the right time is a critical task for manufacturers,

as a thorough understanding of manufacturing tools leads to better-designed production processes

and consistent delivery of high-quality, stable products.

How to Implement

Evolution of Factory Maintenance Practices

Refining Maintenance Plans to Extend Equipment Lifespan

Corrective Maintenance (CBM) / Maintenance only after machine failure

Preventive Maintenance (PM) / Time-based scheduled maintenance

Predictive Maintenance (PDM) / Identifying existing issues, determining the optimal time for repair,

adjusting maintenance plans, and preventing total machine failure

Prognostics and Health Management (PHM) / Reducing failure factors, optimizing maintenance tasks,

and extending equipment lifespan

How to Implement

Ideal Predictive Maintenance

Quality Enhancement and Data-Driven Management

Maintenance strategies are gradually shifting toward predictive maintenance.

In essence, this means utilizing various measurement technologies to assess the current health status of equipment.

By detecting even the slightest symptoms of an issue early,

operators can take immediate action or schedule repairs in advance.

This ensures consistent quality and reliability of production equipment,

while utilizing data-driven management to improve product yield, prevent unexpected downtime,

and extend machine lifespan.

The ideal predictive maintenance should:

・Not interfere with machine operation

・Not affect productivity or quality

・Allow non-invasive inspection (non-destructive testing)

・Not cause damage to equipment

・Provide diagnostic capabilities

・Trace the source of anomalies

How to Implement

Machine Health Diagnosis Signs

The Role of Vibration

Changes in vibration indicate variations in machine operation,

and increased vibration usually signifies a developing issue.

Vibration itself is merely a symptom; reducing vibration means addressing its root causes.

The forces generating vibration often originate from factors like imbalance or misalignment.

Measured machine vibrations are a combination of multiple frequencies, amplitudes, and phase angles.

While vibration cannot be entirely eliminated, it can be managed within acceptable limits.

Implementation Benefits

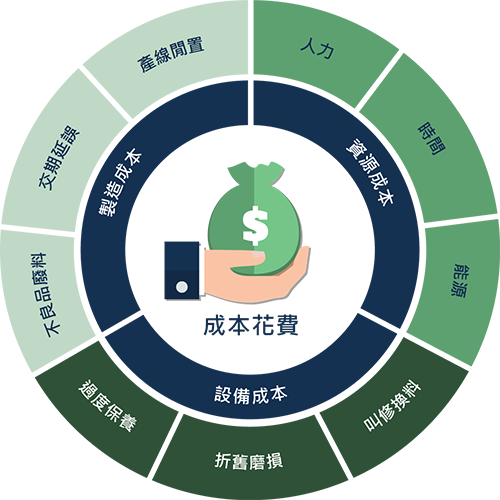

Reducing Unnecessary Costs Through Predictive Maintenance

Hidden Costs in the Manufacturing Process

Whether sending machines for factory maintenance or having in-house technicians inspect and repair equipment,

customer service teams often evaluate whether maintenance or part replacements are needed.

However, in many cases, parts are replaced simply because a certain amount of time has passed,

or machines are disassembled to inspect problem areas, leading to unnecessary replacements of all parts.

This wastes both time and labor.

Additionally, once the cause of failure is identified, some replacement parts may need to be sourced from overseas,

leading to long delivery times and increased downtime waiting for repairs.

Even after maintenance is completed and the machine is returned to the factory,

how can we evaluate whether the maintenance was effective?

If the machine’s utilization rate does not improve after servicing,

the entire process results in unnecessary costs.

In recent years, manufacturing industries have increasingly focused on improving

product yield rates and production capacity.

As factory production processes become more refined,

the demands for precise equipment operations have also increased.

With our system, real-time equipment monitoring enables

accurate tracking of machine conditions and the collection of large-scale data

for predictive maintenance (preventive maintenance) planning.

By detecting early failure patterns,

we can prevent unplanned downtime, ensure smooth production flow,

maintain manufacturing quality, and protect equipment integrity.

This ultimately leads to optimized production processes, reduced costs,

and improved production yield and efficiency.

By identifying root causes of machine failures and properly addressing anomalies,

we achieve the optimal predictive maintenance solution,

prevent hidden costs, and minimize losses,

ultimately generating higher profits for your business.