Rotating Machinery Rotor Category

Case|Rotating Machinery Rotor Category

Monitoring rotor machinery provides multiple benefits for factories.

By tracking the operational status of rotor machinery and implementing preventive and predictive maintenance, potential failures and issues can be detected early.

High-Load Operation Over Time Causing Critical Motor Failure?

Continuous high-load operation of equipment can lead to excessive vibration due to prolonged use or external environmental factors.

If critical equipment fails, it may result in significant losses.

Exhaust Fan Motor Malfunction Impacting Production?

A sudden failure of the exhaust fan motor can cause the fan to stop functioning properly, significantly affecting the production process or environment.

In some manufacturing processes, it is essential to quickly remove specific gases or chemicals from the equipment to maintain stable process conditions.

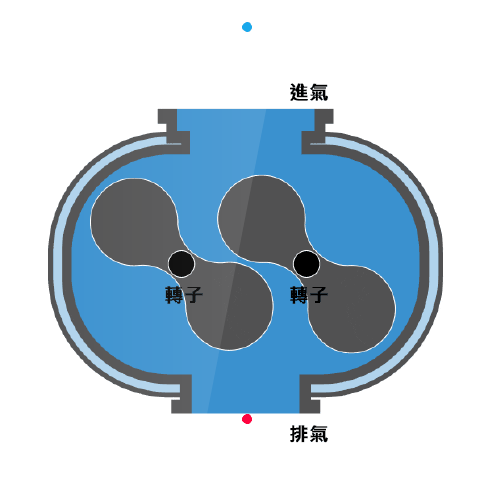

How to Quickly Diagnose Vacuum Dry Pump Abnormalities?

In semiconductor manufacturing, many processes rely on vacuum pumps.

Among them, Dry Pumps have a critical impact on production.

How can we prevent unexpected equipment shutdowns?

Turbo Pump Experiencing Dynamic Imbalance?

The most critical factor in Turbo Pump magnetic levitation bearings is dynamic balance.

Higher rotational speeds and frequencies indicate poor dynamic balance.

How can we measure and correct this issue?

Motor Producing Loud Noise – Which Component is Faulty?

When precision machining motors or pumps produce excessive noise during operation, it is a clear sign of an abnormal condition.

How can we use experience-based analysis to determine if the mechanical system has a problem and pinpoint the faulty component?

Cylinder Malfunction Causing Insufficient Thrust?

A malfunctioning pneumatic cylinder may cause air pressure backflow, preventing proper pressure regulation and reducing thrust force.

How can we detect such abnormalities early to prevent disruptions in the manufacturing process?

Does Reflow Oven Blower Motor Vibration Affect Temperature?

Reflow soldering gradually melts the solder and slowly heats the bonding interface to prevent sudden heating damage to electronic components.

Therefore, the quality of the blower motor is closely related to temperature control.