Does Exhaust Fan Motor Abnormal Rotation Affect the Process?

Case|Does Exhaust Fan Motor Abnormal Rotation Affect the Process?The sudden failure of the exhaust fan motor can cause the fan to stop functioning properly, potentially leading to significant impacts on the process or environment.

Exhaust Fan Motor

Impact of Exhaust Fans on Environment and Process Quality

Multi-exhaust fan systems are commonly used to remove gases or gas mixtures generated during manufacturing processes. In certain processes, it is crucial to rapidly discharge specific gases or chemical agents to maintain stable processing conditions. Exhaust fans provide the necessary airflow to facilitate the efficient expulsion of these gases, reducing potential contamination and variability, thereby enhancing product consistency and quality.

Moreover, many chemical agents and gases are toxic, flammable, or even explosive. Exhaust fans can effectively remove these hazardous gases from the equipment, reducing workplace contamination and ensuring worker safety. Controlling the release of these gases helps minimize environmental impact.

Therefore, if the exhaust fan fails to operate correctly, gases generated during the process may accumulate inside the equipment, leading to increased pressure or excessive gas concentration. This can affect critical parameters such as temperature, pressure, or chemical concentrations, ultimately impacting product quality and process stability.

In more severe cases, an increase in gas concentration in the workplace may pose health risks to employees, potentially leading to hazardous exposure. In certain situations, this could even result in fire or explosion hazards.

Common Causes of Exhaust Fan Malfunctions:

Mechanical Failure: The mechanical components of the exhaust fan may experience wear and tear, aging, or failure, leading to malfunctions. For example, damage to fan bearings, broken or deformed fan blades, etc.

Electrical Issues: Exhaust fans can be affected by electrical system failures, such as faults in the electric motor, controller, or wiring. These issues may cause the fan to fail to operate correctly or lose control.

Dust Accumulation and Blockage: The air inlet or exhaust outlet of the fan may become clogged with dust, debris, or other substances, leading to restricted airflow and reduced operational efficiency.

Environmental Factors: External environmental factors such as extreme weather, dust, or humidity may impact the exhaust fan’s operation by reducing efficiency or causing corrosion and other issues.

Solutions and Monitoring Explanation

RM-IoT-NET Wired Rotor Monitoring System

The RM-IoT-NET wired rotor monitoring system enables real-time monitoring of the health and quality status of exhaust fans. These fans are often located in special environments such as chemical plants, underwater areas, high-temperature and high-pressure conditions, explosion-prone zones, and corrosive media environments. To ensure safe operation and reliability of the equipment, rotor monitoring requires stringent methods and the use of specialized sensors that comply with environmental standards and requirements, ensuring careful execution of monitoring tasks.

Measurement Status

RM-IoT-NET Monitoring Main Screen

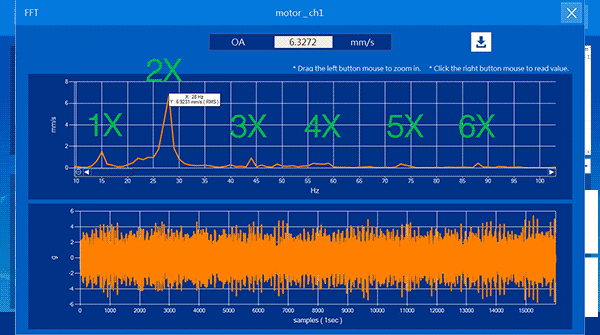

Standard ISO10816-3 15~75kW Rotor Drive Motor Detection Result: Warning

Frequency Exceedance Trend Chart:Red Line Indicates the Time Point of Passivation Mold Replacement.

Based on the detection results, it is evident that the drive motor exhibits excessive 2x frequency anomalies. By comparing spectral characteristics, the probable causes could be misalignment or mechanical looseness issues.

Vibration Characteristics of Misalignment

Vibration frequencies mainly occur at 1x, 2x, or 3x rotational speeds.

Most misalignments are mixed types (angular + parallel), thus vibrations originate from both radial and axial directions.

Vibration Characteristics of Mechanical Looseness

Whether it's external or internal looseness, the spectrum will show distinct 1x, 2x, 3x...7x, 8x, or higher rotational frequency components. Both radial and axial directions exhibit similar characteristics. However, there are subtle differences between the spectra of external and internal looseness.

Measurement Conclusion

Regular inspection, maintenance, and servicing of exhaust fans are crucial. By monitoring the system, we can ensure that the exhaust fan is operating normally and promptly address any potential issues. Furthermore, through long-term trend monitoring, we can predict possible failure points and implement effective predictive maintenance to prevent unexpected downtime and potential workplace hazards.

RM-IoT-NET Wired Rotor Monitoring System