Rotor Equipment in Special Areas

Download

Rotor Health Monitoring System - Network Edition

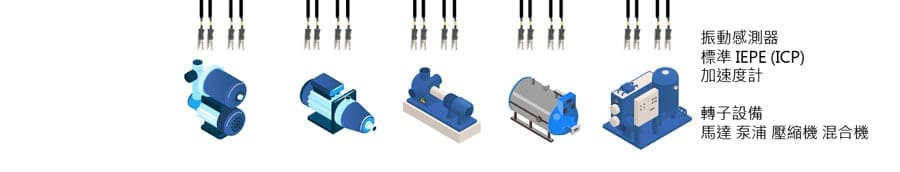

Equipped with Suitable Specialized Sensors

Why is it necessary?

Common Challenges in Monitoring Rotor Equipment in Special Areas?

Varied Environmental Conditions

How to centrally manage rotor equipment in special environments such as high temperature, high pressure, or underwater areas?

Weak Signal in Remote Locations

How to transmit data effectively when equipment is located in remote areas with poor connectivity?

Difficult Software Operation

How to simplify monitoring system settings to make operation easier and facilitate quick handovers?

Difficult Equipment Status Interpretation

How to standardize equipment status assessments using data instead of relying on subjective human experience?

Maintenance Efficiency Evaluation

How to determine whether outsourced maintenance is cost-effective? When should the equipment be serviced?

Data Collection & Work Planning

How to effectively use large amounts of collected data to implement predictive maintenance strategies?

Problem Solving

How to Monitor Rotor Equipment in Special Areas?

Rotor equipment in special areas often operates in extreme or hazardous industrial environments,

which imposes higher demands on their monitoring and maintenance. These requirements include

safety, reliability, durability, and adaptability to special environmental conditions. When

designing, installing, and operating such equipment, relevant safety standards and regulations

must be strictly followed.

Special areas such as chemical plants, underwater zones, high-temperature and high-pressure

environments, explosion-prone areas, and corrosive media require rigorous monitoring to ensure

safe and reliable equipment operation. In addition to strict and challenging monitoring

conditions, it is also necessary to use specially designed sensors that meet environmental

standards and requirements to carefully execute monitoring tasks.

Feature Description

Different Sensors for Different Environmental Conditions

In special industrial environments such as chemical plants, underwater zones, high-temperature and high-pressure areas, explosion-prone zones, and corrosive media areas, RM-IOT-NET Rotor Health Monitoring System (Network Version) selects different types of sensors according to the environmental conditions.

These include dust-proof and explosion-proof sensors, high-temperature resistant sensors, and waterproof sensors. All collected data can be integrated into a central system for unified monitoring in a command center.

Feature Description

Built-in International ISO Standards, Easy to Use Without Technical Background

RM-IOT-NET Rotor Health Monitoring System (Network Version) is suitable for all types of rotating machinery and rotor equipment. The system comes with built-in ISO 10816 and ISO 2372 vibration standards, eliminating the need for users to memorize complex reference tables.

Users only need to select the appropriate standard according to equipment

power and size to easily conduct measurements. No specialized technical

background is required to operate the system.

Furthermore, our system surpasses conventional monitoring software by

incorporating the latest ISO 20816 standard, providing a more

comprehensive measurement framework for rotor and motor components.

Feature Description

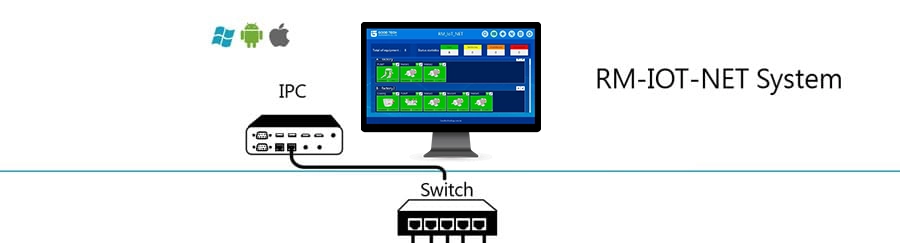

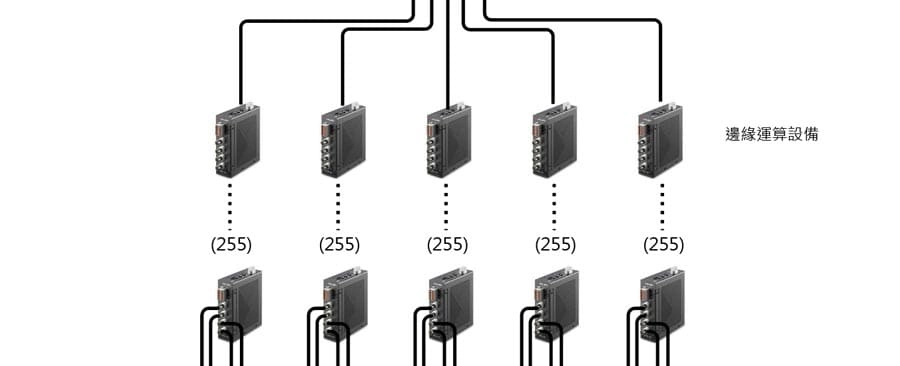

Daisy-Chain Network Topology Technology, Reducing Future Expansion Costs

RM-IOT-NET Rotor Health Monitoring System (Network Version) is equipped with four-channel analog input and adopts a daisy-chain network topology. The main system is connected via RJ45 Ethernet module, supporting up to 255 nodes.

Additionally, it seamlessly integrates with AI, FDC, MES, PHM, and SCADA systems. The high flexibility of serial connections significantly reduces system integration costs, meets scalability requirements, and optimizes both space utilization and budget allocation.

Feature Description

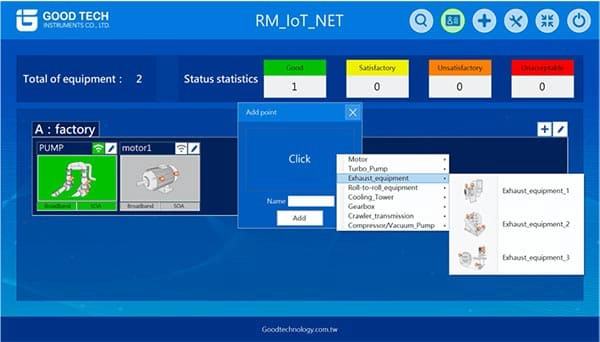

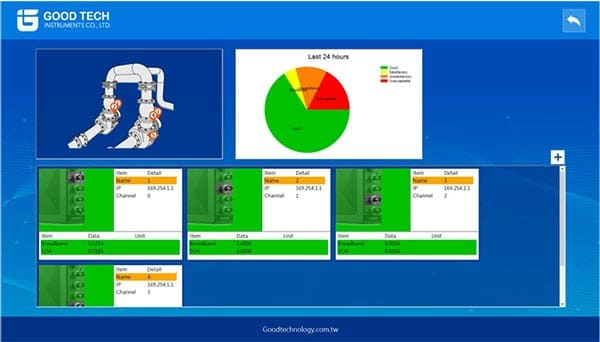

Integrate Equipment Inspection Data, Return to IoT Command Center Management

RM-IOT-NET Rotor Health Monitoring System (Network Version) stands out by consolidating data and integrating it into an IoT system. Regardless of the brand of rotor equipment, all status results can be displayed on a single platform, allowing for centralized Command Center Management.

This feature enhances users' ability to assess equipment conditions in real time, reducing troubleshooting time and improving operational efficiency. By combining scientific data management with a comprehensive database, the system enables continuous real-time monitoring, providing a solid basis for predictive maintenance planning and execution.

Feature Description

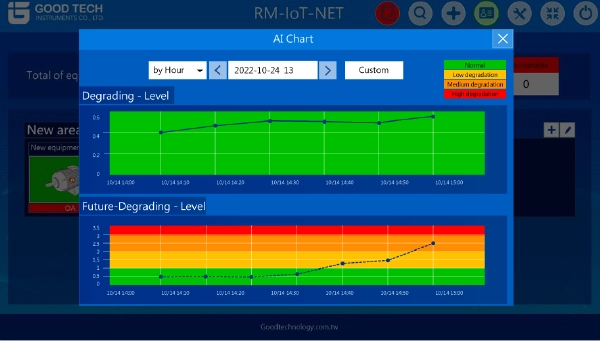

AI Predicts Degradation, Enables Early Spare Parts Preparation and Maintenance Planning

RM-IOT-NET Rotor Health Monitoring System (Network Version) is equipped with an AI-based degradation prediction feature, integrating a pre-trained monitoring model with Rule-Based Management Principles and Residual Life Prediction.

Users can configure their desired prediction range, such as weekly or monthly forecasts. The system displays trend graphs with a color-coded background (Green, Yellow, Orange, Red) to indicate different levels of degradation, helping users plan budgets and allocate manpower in advance.

Stability of Equipment

in Special Areas

In addition to the challenges of monitoring rotor equipment in special areas, the stability of these devices directly impacts production line operations and product quality. RM-IoT-NET Rotor Health Monitoring System (Network Version) helps users ensure equipment stability and reliability, thereby maintaining the overall stability of factory production lines.

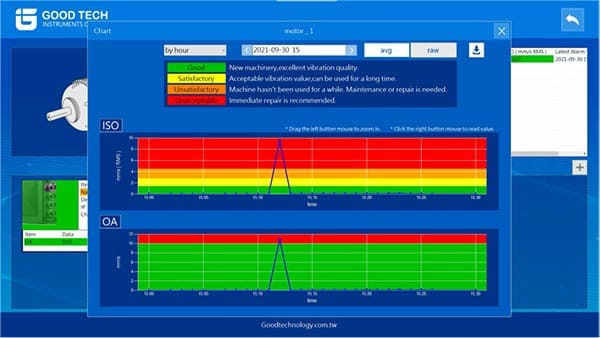

UI Functional Interface

Rotor Quality Standards & Equipment Status at a Glance

RM-IOT-NET Rotor Health Monitoring System (Network Version) is built with ISO 10816 / 20816 / 2372 standards, applicable to various rotary machinery from semiconductor to manufacturing industries (motors, compressors, pumps, etc.). Users do not need to memorize standard tables; they only need to apply the appropriate standard based on motor output range. The software uses color-coded indicators to distinguish equipment status: Excellent, Normal, Warning, and Dangerous, allowing users to make timely maintenance decisions.

UI Functional Interface

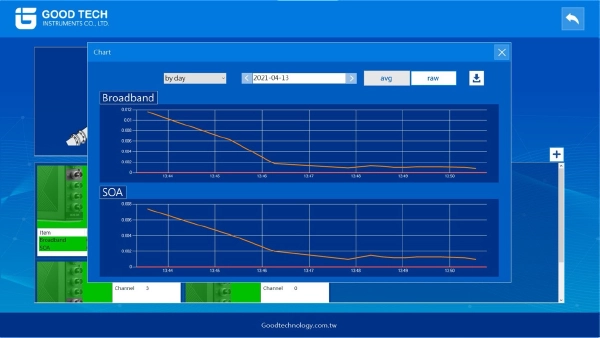

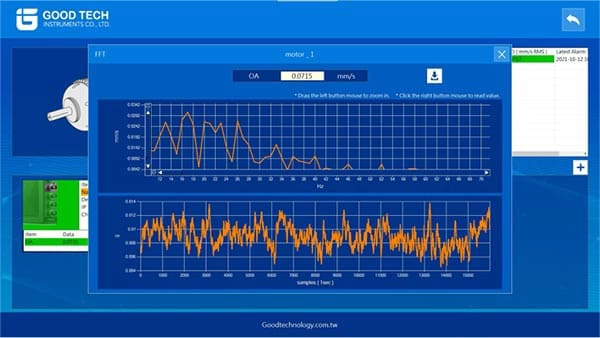

Special Algorithm SOA Spectrum Features

RM-IOT-NET Rotor Health Monitoring System (Network Version) features SOA special algorithm developed by GoodTech. It effectively suppresses noise for clearer and more efficient resolution, making early fault detection 4 times more effective than conventional algorithms on the market. The system also provides diagnostic insights based on spectrum features, helping identify potential abnormalities.

UI Functional Interface

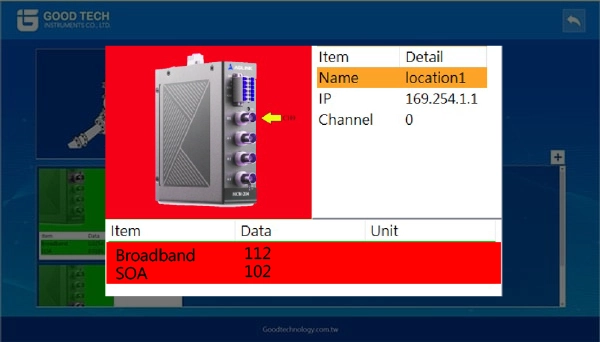

User-Defined Standards & Human Experience Management

For specific equipment requiring special management, users can set threshold values for Broadband and SOA

by incorporating human experience or using manufacturer-provided parameters.

The system displays green for normal and red for warnings. When data exceeds the preset threshold,

the values are shown in red warnings, effectively helping users implement graded management of equipment

and ensuring precise monitoring of device conditions.

UI Functional Interface

AI Degradation Prediction for Inventory & Maintenance Planning

The AI degradation prediction function is built with specification-trained monitoring models,

integrating RULE BASE management principles and residual life prediction.

Users can customize the prediction range, such as weekly or monthly forecasts, and view trend analysis through graphical representation.

Background colors indicate different statuses, helping users plan budgets and workforce allocation in advance.

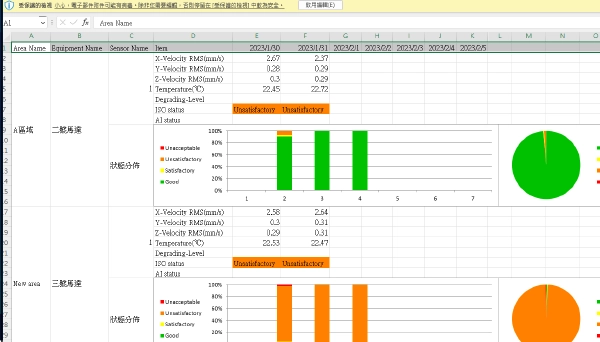

Still wasting time manually compiling statistical reports?

The Motor Rotor Map Inspection & Measurement System includes a built-in report export function, allowing users to filter by region, equipment, status, etc.,

making data compilation faster and more convenient.

Application Targets

Suitable for Various Special Area Equipment

Petrochemical Equipment:

Includes rotor equipment in refineries and chemical plants, such as compressors and pumps,

which often operate in flammable and explosive environments.

Coal Mining Equipment:

Rotor equipment used in coal mining, such as fans, hoists, and coal mining machines,

typically operate in harsh environments with high temperatures, high pressure, and heavy dust.

Offshore Platform Equipment:

Rotor equipment located on offshore platforms, such as generators, water pumps, and fans,

must withstand extreme conditions like seawater corrosion, high humidity, and strong waves.

Steel Smelting Equipment:

Rotor equipment in steel smelting plants, such as blowers, blast fans, and conveyors,

which operate in high-temperature, high-pressure, and high-dust environments.

Power Plant Equipment:

Includes rotor equipment in thermal and nuclear power plants, such as turbine generators and steam turbines,

which function under high temperature, high pressure, and high-speed operation conditions.

Chemical Plant Equipment:

Rotor equipment in chemical plants, such as agitators, reactors, and separators,

which frequently operate in environments with corrosive media, high temperatures, and high pressures.

Core Concept

Layered Management & Predictive Diagnostics

Triple Management Mechanism Provides Accurate Maintenance Guidelines.

Quality Management:

Based on international ISO standards (2372/10816/20816), the system conducts vibration analysis and overall evaluation.

The results are displayed in green, yellow, orange, and red colors, allowing users to take appropriate maintenance

or repair actions based on orange and red indicators. Custom threshold settings are also available.

Feature Diagnosis:

The special SOA algorithm suppresses noise, providing clearer and more efficient resolution.

It enhances early fault detection effectiveness by four times compared to other market algorithms.

Additionally, it offers possible abnormal feature diagnostics based on spectral characteristics.

Predictive Anomalies:

The system incorporates leading AI algorithms, collecting massive data for cross-analysis and visualization.

It predicts equipment degradation trends over the next 7 days, providing users with more precise maintenance scheduling.

Core Concept

RM-IoT-NET Ensures Reliable Management

Layered Management

Easy Expansion

Flexible Architecture

Centralized Management

Enhanced Efficiency

Real-time Monitoring

Architecture Overview

RM-IOT-NET Rotor Health Monitoring System (Network Version)

(Network Topology)

Support

Other Rotor Equipment Related Topics