Does the Vibration Quality of the Reflow Oven Blower Motor Affect Temperature?

Case|Does the Vibration Quality of the Reflow Oven Blower Motor Affect Temperature?Reflow soldering gradually melts the solder and slowly heats the connection interface to prevent damage to electronic components caused by rapid heating. Therefore, the quality of the blower motor is closely related to temperature control.

Reflow Soldering

Reflow soldering is a common surface mount technology (SMT) used to solder surface-mounted components (SMT components) onto printed circuit boards (PCBs).

This soldering process typically uses solder paste and is carried out using a device called a reflow oven.

Solder paste is applied or printed onto the PCB using templates that align with the soldering positions, and the SMT components are placed at the designated solder joints.

General Process of Reflow Soldering:

Preheat Zone: The PCB enters the preheat zone of the reflow oven. The temperature gradually rises to preheat the solder paste to its melting point without causing soldering yet.

Reflow Zone: The PCB enters the reflow zone, where the temperature is high enough to melt the solder paste. The melted solder connects the SMT components to the PCB, forming solder joints.

Cooling Zone: The soldered PCB enters the cooling zone, where the solder joints solidify. Proper cooling ensures uniform joint formation and strength.

Reflow Oven

The reflow oven is a crucial piece of equipment in PCB manufacturing. Its primary function is to gradually melt the solder and slowly heat the connection interface,

followed by cooling to achieve proper electronic component soldering while preventing thermal damage due to rapid heating.

Reflow Oven Air Circulation System

The hot air motor and fan work together to distribute hot air evenly within the oven chamber.

This ensures that the solder paste on the PCB pads melts uniformly, allowing the components to bond with the board effectively.

After passing through the cooling stage, solid solder joints are formed.

Therefore, the performance of the reflow oven blower motor significantly impacts soldering quality,

and monitoring the motor's condition is essential to ensuring product quality.

Monitoring Explanation

SMS-RC Rotating Machinery Vibration Detection Analyzer

The SMS-RC system is used to measure motor quality by directly selecting corresponding rotor ISO standards.

It provides immediate verification of the hot air system's motor performance, preventing motor failures or abnormalities that could lead to temperature control issues

and product defects, ensuring the normal operation of the reflow soldering process.

Measurement Conditions

Measurement points are shown in the diagram below, with a total of 14 measurement points.

Measurement Results

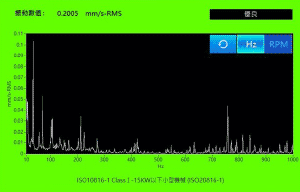

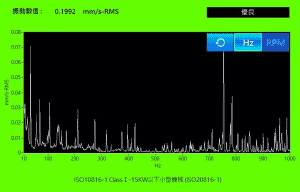

Motor 1

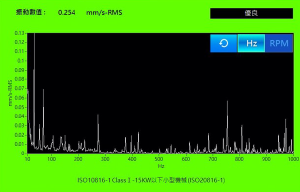

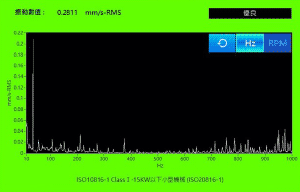

Motor 2

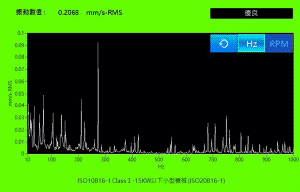

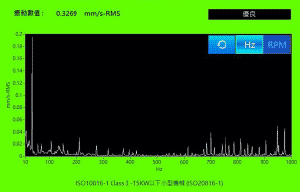

Motor 3

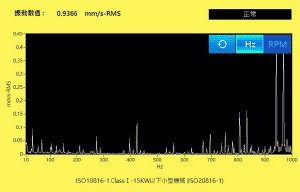

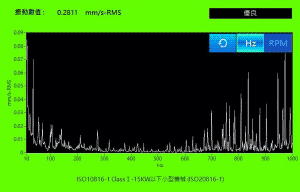

Motor 4

Motor 5

Motor 6

Motor 7

Motor 8

Result Explanation

Measurement Conclusion

The SMS-RC Rotating Machinery Vibration Detection Analyzer enables rapid assessment of motor quality. Based on the results, it can be observed that all blower motors are in excellent condition except for Motor 4 and Motor 13, which are in normal condition. Future monitoring can be conducted using RM-IoT-NET for long-term online management, enabling timely maintenance actions when warning signals are detected to prevent unexpected shutdowns that may cause abnormal temperatures inside the reflow oven, ultimately ensuring product quality.

SMS-RC Rotating Machinery Vibration Detection Analyzer