How to Detect Abnormal Operation of Pneumatic Cylinders?

Case|How to Detect Abnormal Operation of Pneumatic Cylinders?A pneumatic cylinder uses compressed gas as power. When it malfunctions, it may cause airflow backflow, leading to pressure regulation failure and insufficient thrust. How can abnormalities be detected early to prevent process disruptions?

Principle of Pneumatic Cylinder Operation

A pneumatic cylinder is a mechanical component that uses compressed gas to drive mechanisms and produce reciprocating linear motion. During operation, compressed gas enters the cylinder from one end of the piston, applying pressure to displace the piston.

Abnormalities in pneumatic cylinders can arise due to various factors, such as valve clogging caused by oil contamination or valve body wear, misalignment of the piston causing failure to operate, and foreign objects leading to cylinder scuffing. How can monitoring be used to prevent process disruptions caused by excessive wear, aging, and deformation?

Solution and Monitoring Explanation

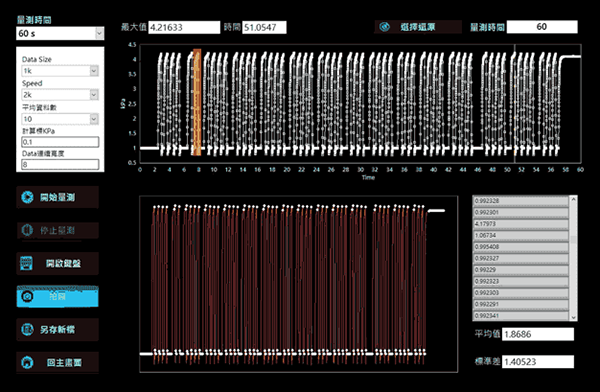

VMS-PH Dynamic Equipment Analyzer

Measures the repeatability of pneumatic cylinder operation in the process and categorizes signal sections based on process stages. By understanding the running conditions of the screw, the system evaluates the cylinder's operation quality. The VMS-ML machine learning intelligent system provides online monitoring and trend management for predictive maintenance planning.

Measurement Condition

Real-time Screw Vibration Measurement

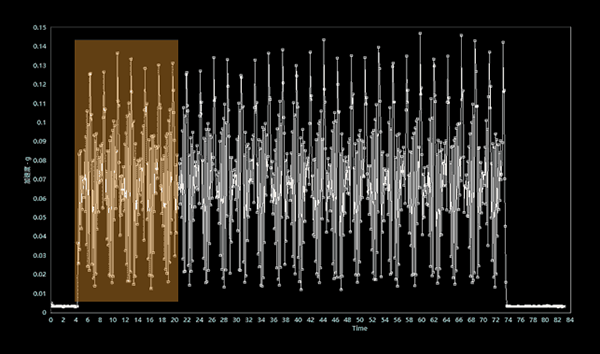

Vibration Signals

Visualization of screw vibration signals.

Zoom in 0~20sec Signal Area

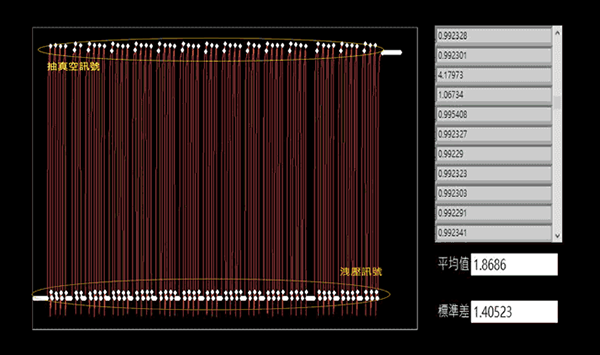

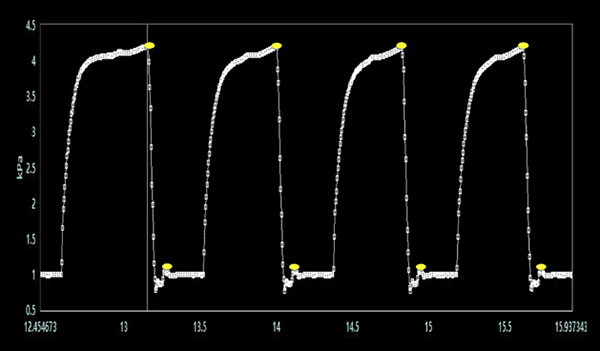

Comparison of Vibration Signals in 4 Process Cycles

Condition A: Stable Operation

Condition B: Large Timing Differences, Unstable

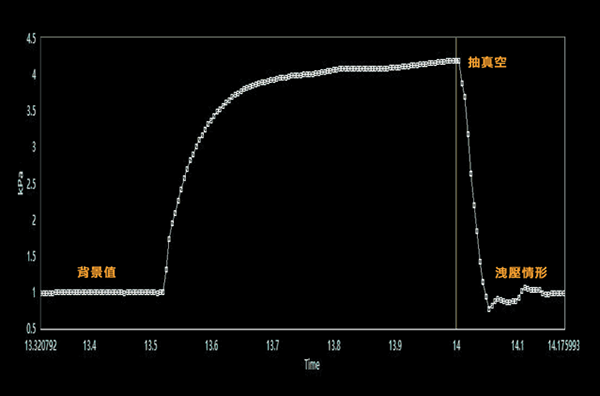

Full Process Pneumatic Cylinder Measurement

Pneumatic Cylinder Operation Signals in the Full Process

Zoom in Signal

Measurement Conclusion

Average Value Management: Real-time monitoring of signal changes within the working interval.

Standard Deviation Management: Real-time stability assessment of operational signals within the working interval.

The VMS-PH Dynamic Analysis Monitoring System features edge computing, integrating signal processing algorithms directly into the firmware. It automatically captures the most significant signals at the edge, the maximum group standard deviation within the effective interval, or characteristic surge points. These extracted feature data are then transmitted to the management system for predictive maintenance and trend analysis. Additionally, a database is established within the system to collect feature data.

The key advantage is that it does not overly consume factory network bandwidth, and the collected feature data (appropriately cleaned) is suitable for clients to conduct their AI training and optimize proprietary AI monitoring models.