Portable & Versatile – Suitable for Various Applications

Key Features

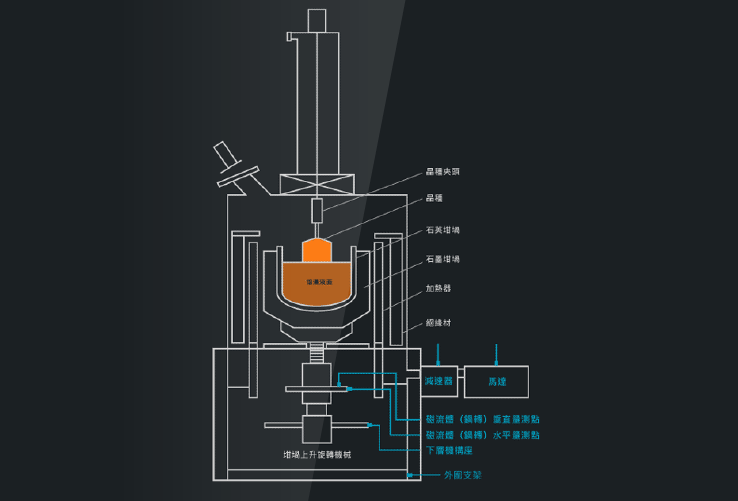

Measure Dynamic Signal Changes in Various Components

VMS®-PH Equipment Dynamic Analyzer is a vibration measurement and analysis device designed for high-end precision instruments.

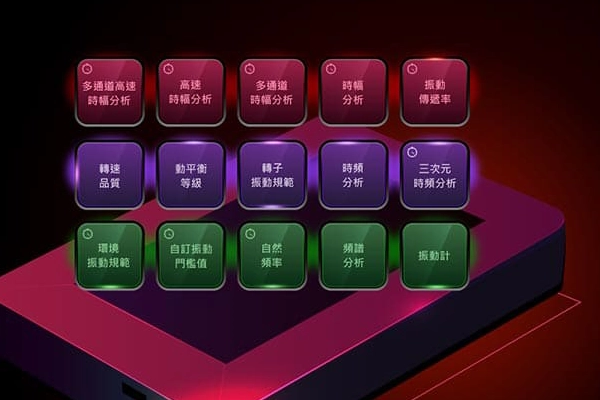

It integrates more than 20 vibration measurement-related features, including spectrum analysis, time-frequency analysis, vibration transmissibility, and dynamic analysis.

It allows on-site measurement and analysis directly at the machine requiring troubleshooting,

helping users quickly and accurately identify the root cause of equipment issues and restore normal production line operation,

ensuring the expected uptime of machinery and equipment.

Key Features

The Most Powerful Portable Measurement Device

VMS®-PH Equipment Dynamic Analyzer is highly portable, featuring a touch screen, four sensor input ports, and a USB transmission port.

It allows users to take measurements anywhere, making it suitable for various applications.

Supporting ultra-high-speed measurement bandwidth and simultaneous multi-channel sampling,

the system can detect dynamic changes in equipment and instrument components in a very short time.

Users can also customize software functionality based on specific requirements.

Key Features

Built-in Advanced Algorithms & ISO Standards

VMS®-PH Equipment Dynamic Analyzer is equipped with a series of advanced algorithms that seamlessly integrate measurement results with ISO standards.

The measured data can be instantly converted into direct quality assessments or classified rankings.

For rotor motor-related measurements, Good Tech surpasses all monitoring software on the market

by incorporating the latest ISO 20816 standard, ensuring more comprehensive management of motor rotor components.

Key Features

A Reference for Equipment Process Design & Development

VMS®-PH Equipment Dynamic Analyzer automatically compares real-time measurement data with its database, providing production process developers with valuable insights for data adjustments, analysis, and production speed optimization. This enables easier fine-tuning of machine operation parameters or testing of equipment performance limits.

Save 36%

Work Time

All vibration measurement functions you can imagine are integrated here, suitable for various monitoring applications: semiconductor factories, machine tools, packaging plants, technology companies, manufacturing plants, facility maintenance providers, rotor machinery, robotic arms, Industry 4.0 smart factories, and more.

High-Speed Multi-Channel Dynamic Analysis

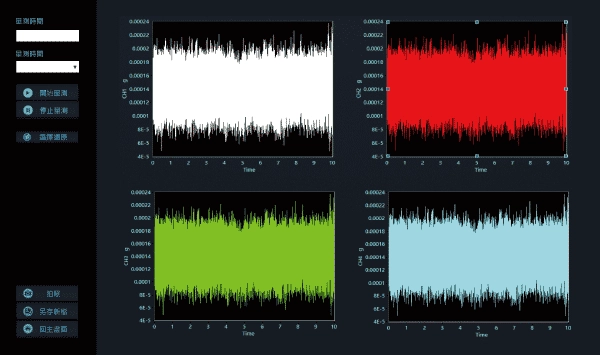

The dynamic analysis device is used to assess the convergence time during dynamic stopping and evaluate the relative vibration between components within an extremely short period. Multiple sensors can be connected to evaluate the level of interference between the main system and mechanical components.

High-Speed Dynamic Analysis

The dynamic analysis device records instantaneous equipment movement changes and micro-movements. It allows adjustments to machine parameters using data, stabilizing machine operation. It can also convert between acceleration, velocity, and displacement as needed.

Multi-Channel Dynamic Analysis

Enables simultaneous measurement of the interaction between different machine components. It records complex dynamic behavior in multiple channels, making it a highly convenient tool for analyzing changing dynamic conditions.

Dynamic Analysis

For repetitive cyclical movements or variable equipment operations, the built-in proprietary algorithm accurately records and maps the micro-movements of robotic arms and mobile devices. It provides real-time assessment of motion quality.

Vibration Transmission Rate

For the vibration isolation effect of vibration isolation platforms, the equipment dynamic analyzer can easily interpret the current vibration isolation efficiency and its ability to filter various frequency components. The graph displays the transmission status of each vibration component.

Rotational Speed Quality

If variable-speed equipment is accidentally operated at resonant rotational speeds or their multiples, it could cause equipment damage. It accurately depicts the vibration quality of equipment in the rotational speed range, providing reference for optimal setting parameters.

Dynamic Balance Level

Rotating machinery and rotor devices require standard dynamic balance calibration. As the frequency of use increases, the originally calibrated dynamic balance gradually deteriorates. The instrument includes a built-in standard dynamic balance level measurement function.

Air Bearing Vibration Quality

The VMS®-PH equipment dynamic analyzer measures the resonance phenomenon caused by spindle rotation within the measurement range for air-bearing spindles with controllable rotation speed. It can switch between acceleration and velocity units.

Rotor Vibration Quality

The system software integrates built-in ISO Rotor Vibration Standards with real-time calculation and judgment, allowing users to immediately assess the quality of current motor, pump, compressor, and other rotor components.

3D Time-Frequency Analysis

The equipment dynamic analyzer records the overlay of frequency spectra of all dynamic changes within time and, combined with specific analysis functions, allows for fast analysis of frequency information at any specific point during fluctuating times.

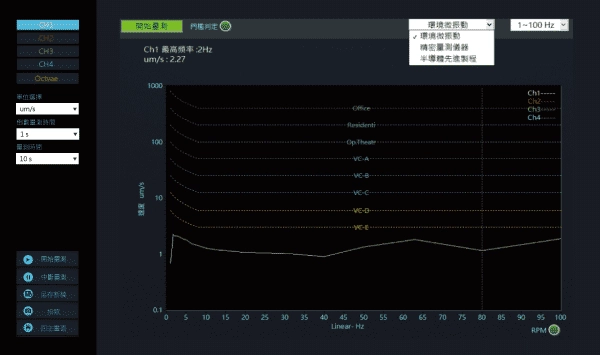

Environmental Vibration Standards

The built-in standard environmental micro-vibration measurement standards, combined with a three-axis adapter, enable users to easily measure the micro-vibration level of the environment, and instantly assess the standards of the equipment's placement or vibration isolation platform.

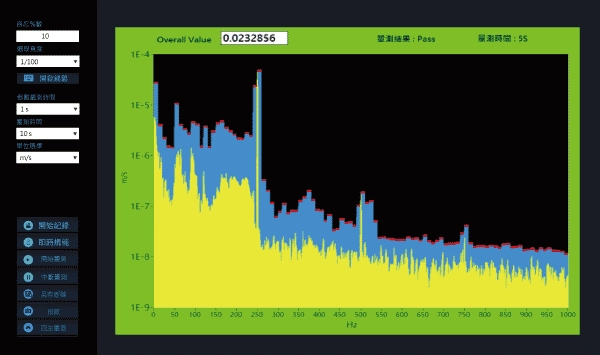

Smart Threshold Frequency Standards

For complex multi-action systems, it provides self-learning and quick establishment of equipment inspection standards. Users can define their own inspection criteria within the factory for different equipment or actions.

Structural Natural Frequency

Analyze the structural natural frequencies that exist when mechanical equipment is placed in its current environment. This provides users with the basis for future structural reinforcement or design adjustments, preventing resonance from affecting the equipment.

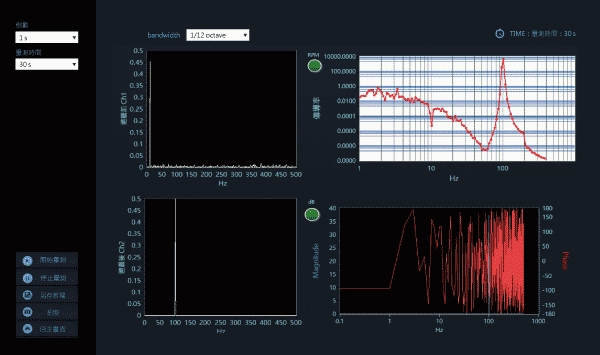

Multi-functional Frequency Analysis

The system has a powerful and complete frequency analysis function, supporting both time-domain and frequency-domain measurements. It offers easy switching between standard Octave frequencies and supports conversion between various physical units and linear transformations.

Vibration Meter

You can connect a multi-channel measurement device to measure the vibration values at each measurement point. Read the values on-site to easily identify the magnitude of vibrations at each measurement point. It also allows conversion between various vibration units such as acceleration, velocity, and displacement.

Feature Description

UI Function Screens

Vibration Transmission Rate

Measures the signal difference between two accelerometers, and can measure vibration transmission rate, phase shift, etc.

Smart Threshold Frequency Specification

Custom inspection standards for different vibration qualities, allowing users to set bandwidth, standard values, and permissible tolerances.

Environmental Vibration Specification

Based on environmental vibration guidelines, measures vibration targets and classifies vibration levels.

High-speed Multi-channel Dynamic Analysis

Opens multiple channels simultaneously for high-speed vibration measurements, comparisons, and recordings of various vibration behaviors.

Application Description

Recommended Measurement Types and Application Functions

| Measurement Type | Application Function |

|---|---|

| Pump | Rotor vibration standard, dynamic balance grade, spectrum analysis |

| Blower | Rotor vibration standard, dynamic balance grade, spectrum analysis |

| Compressor | Rotor vibration standard, dynamic balance grade, spectrum analysis |

| Motor | Rotor vibration standard, dynamic balance grade, spectrum analysis |

| Machining Spindle | Rotor vibration standard, dynamic balance grade, spectrum analysis |

| Fan | Rotor vibration standard, dynamic balance grade, spectrum analysis |

| Spectrum Analysis | Spectrum analysis |

| Robot Arm Motion Monitoring | Time Amplitude Analysis |

| Environmental Vibration Measurement | Environmental vibration standard |

| Confidential Equipment Placement Environment Measurement | Environmental vibration standard |

| Precision Manufacturing Equipment Placement Environment Measurement | Environmental vibration standard |

| Screw, Slide Rail, and Other Motion Monitoring | Time Amplitude Analysis |

| Various Conveyor Device Motion Monitoring | Time Amplitude Analysis |

| Vibration Isolator, Vibration Platform Measurement | Environmental vibration standard, vibration transmission rate |

| Precision Equipment Composite Motion Vibration Monitoring Analysis | Time Amplitude Analysis, Time Frequency Analysis |

| Large Slow Rotating Equipment Vibration Monitoring Analysis | Time Amplitude Analysis |

| Variable Speed Equipment Vibration Monitoring Analysis | Time Amplitude Analysis |

| Fixed Frequency Component Analysis | Spectrum Analysis |

| Vibration Behavior Independent of Time | Spectrum Analysis, Vibration Transmission Rate, Rotor Vibration Standard, Dynamic Balance Grade |

| Vibration Behavior Dependent on Time | Time Frequency Analysis, Time Amplitude Analysis |

| Simple Predictive Maintenance Testing | Rotor Vibration Standard, Custom Vibration Threshold, Environmental Vibration Standard, Dynamic Balance Grade |

| Professional Predictive Maintenance Monitoring with Data Analysis | Time Frequency Analysis, Time Amplitude Analysis |

Application Fields

Applicable to Various Industry Sectors

VMS®-PH Equipment Dynamic Analyzer is suitable for any equipment requiring measurement analysis, debugging, and identifying abnormal vibration sources during operation. It is applicable in various industry fields, such as precision equipment, rotor equipment quality inspection, vibration isolation systems, machine tools, factory equipment monitoring, environmental vibration measurement, transportation, semiconductor factories, packaging factories, petrochemical plants, manufacturing plants, power plants, automotive factories, etc.

Machine Inspection

Check if equipment components

are operating properly

Production Line Quality

Check if production line vibrations

affect product quality

Rotary Machines

Inspect rotor motors

and other rotary equipment

Arm Inspection

Inspect movements

of robotic arms

Development Basis

Data can be used by

process developers

Predictive Maintenance

Simple predictive maintenance

inspection function

Fault Diagnosis

Identify the root cause

of equipment issues

Installation Environment

Inspect the installation

environment of precision equipment