Does Environmental Micro-Vibration Affect Equipment Accuracy?

Case|Does Environmental Micro-Vibration Affect Equipment Accuracy?Using the VC-Curve classification standard to plan and position precision instruments helps to avoid performance degradation or decreased accuracy caused by environmental micro-vibrations, thereby preventing unnecessary cost increases.

Environmental Micro-Vibration

Environmental micro-vibration refers to the extremely small vibrations generated in natural environments or within buildings. These vibrations can originate from factors such as the structural strength of factory floors, the operation of equipment, the influence of other machinery, noise within the facility, or vibrations caused by personnel and transport vehicles moving around. Some industries that are highly sensitive to such vibrations include:

Electronics Manufacturing: Environmental micro-vibration can lead to poor soldering of electronic components, which in turn affects the quality and reliability of electronic products. Testing electronic components in an environment with abnormal micro-vibrations can also become challenging, as vibrations may interfere with the proper operation of testing equipment.

Research Laboratories: In environments requiring high-precision experiments, micro-vibrations can introduce uncertainties in experimental results, affecting research accuracy. Vibrations may also reduce the precision of scientific instruments, impacting the reliability of experiments.

Semiconductor Industry: In semiconductor manufacturing, micro-vibrations can affect the stability of photolithography equipment. Photolithography is a high-precision process used to transfer patterns onto semiconductor wafers. Micro-vibrations can cause misalignment of the photolithography equipment, leading to inaccuracies in pattern positioning and affecting wafer manufacturing precision. Additionally, micro-vibrations can impact the stability of the Chemical Vapor Deposition (CVD) process, which is used to deposit thin films onto wafers. Vibrations can lead to uneven gas distribution, affecting the uniformity of the deposited layers and ultimately impacting the quality and performance of the wafers.

Therefore, conducting pre-installation environmental assessments helps prevent performance degradation or accuracy issues caused by environmental vibrations, reducing unnecessary costs.

To avoid or mitigate the impact of environmental micro-vibrations, the following measures can be considered:

Vibration Isolation Technology:

Utilize vibration isolation devices such as air flotation tables and spring isolators to reduce the transmission of external vibrations to equipment or experiments. These technologies effectively isolate ground vibrations and enhance equipment stability.

Proper Installation of Machinery:

Ensure that machinery is properly installed and securely fixed to minimize vibrations generated during operation. Positioning equipment away from vibration sources, such as heavy machinery, helps reduce external interference.

Environmental Vibration Monitoring:

Implement an environmental monitoring system to regularly measure and record the levels of micro-vibrations. This helps identify vibration sources and enables appropriate control measures.

Regular Equipment Maintenance:

Conduct regular inspections and maintenance of isolation devices and other anti-vibration facilities to prevent excessive abnormal vibrations caused by mechanical operations and ensure normal functioning.

Monitoring Description

VMS-EM Environmental Micro-Vibration Detection Analyzer

The VMS-EM Environmental Micro-Vibration Detection Analyzer, combined with sensors and directional adapters, measures the environment of intended precision equipment to confirm whether the micro-vibration quality meets the required standards and helps identify the most suitable installation location.

Measurement Conditions

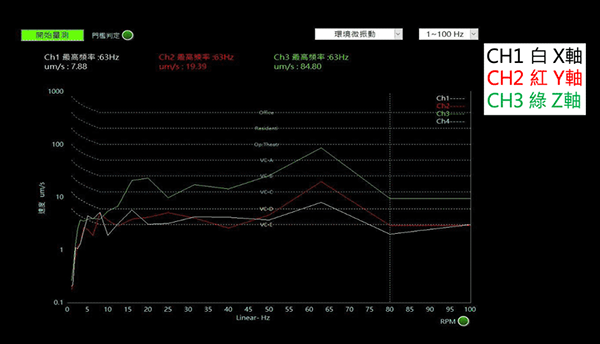

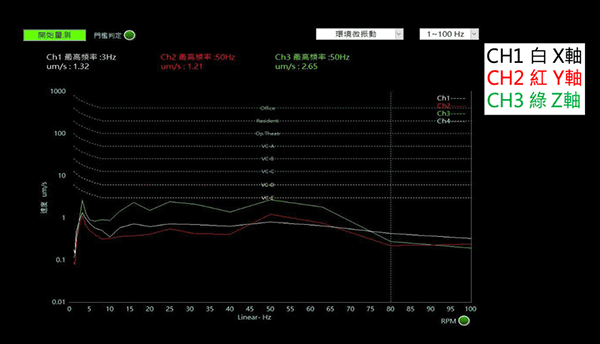

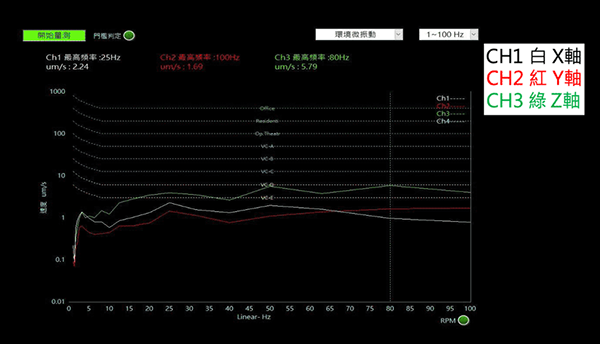

Position A: Operating Theatre Level

Position B: VC-E Level

Position C: VC-D Level

Environmental Micro-Vibration Measurement Levels

• Frequency: 1~100 Hz (1/3 Octave Band Display)

• Unit: Vibration velocity um/s (RMS)

• Duration: 60-second average

• Directions: X, Y, Z axes

Measurement Standard: VC-Curve Micro-Vibration Specification

Measurement Contents: Predefined Measurement Positions A, B, and C

Measurement Conclusions

Position A - Operating Theatre Level:

Vibrations are hardly noticeable, making it suitable for most operating rooms, suites, 100x microscopes, and other low-sensitivity equipment.

Position B - VC-E Level:

Adequate for the most demanding sensitive systems, including long-path, laser-based small target systems, nanometer-scale electron beam lithography systems, and other applications requiring exceptional dynamic stability.

Position C - VC-D Level:

Generally suitable for stringent equipment requirements, including many scanning electron microscopes (SEM and TEM) and electron beam systems.

Based on these results, users can plan the placement of their equipment according to the measured vibration levels at different locations.

By confirming the suitability of the installation environment in advance, installation time and potential vibration mitigation issues can be reduced. The VMS-EM Environmental Micro-Vibration Detection Analyzer is specifically designed to assess micro-vibration levels in factory environments, helping users find the most suitable installation locations.

VMS-EM Environmental Micro-Vibration