Equipment Installation Environment

Download

Environmental Micro-Vibration Detection Analyzer

Prevent Performance Degradation Caused by Environmental Vibrations

Environmental Micro-Vibration

What are the Main Sources of Micro-Vibration?

What is micro-vibration? It is generally defined as vibration with a frequency range of 2–100 Hz and an amplitude below 50 μm/s. Inside the factory, various factors contribute to vibration sources, including floor strength, equipment operation, the influence of other equipment, factory noise, and vibrations caused by workers or moving transport vehicles. External factors include transportation, heavy vehicles passing near the factory, nearby construction, pile driving for buildings, wind, and earthquakes. Any external force acting on the building can cause micro-vibration.

Equipment

Operation

Vibration Isolation

Platform Components

Human Work

Influence

Transport Vehicle

Movement

External Vibration

Influence

Natural Weather

Factors

Why is it needed?

Why do factories need to pay special attention to environmental micro-vibrations?

Equipment performance is affected by environmental vibrations,

and the level of sensitivity to external vibrations varies depending on the precision of the equipment.

Generally, the higher the precision required, the stricter the environmental conditions must be.

For example, atomic force microscopes (AFM), electron microscopes, high-magnification microscopes,

semiconductor lithography machines, and optical component module mirror processing

are highly sensitive to external vibrations, which can significantly impact equipment performance and results.

If the vibration conditions in the factory environment do not meet the vibration specifications required by the equipment,

manufacturing yield will decrease, and measuring instruments will not be able to magnify at higher levels

to detect increasingly fine linewidths. This directly impacts the development of advanced manufacturing processes.

As a result, environmental micro-vibrations are now recognized as a critical factor

that directly affects production yield.

Feature Description

Specialized for Factory Environmental Micro-Vibration Measurement

In high-tech industries such as semiconductors, precision equipment and instruments require stricter environmental vibration standards. While users may not perceive micro-vibrations in the environment, these vibrations can directly impact production machinery and product quality.

By confirming the suitability of the installation environment beforehand, installation time can be reduced, and future vibration issues can be minimized. The VMS®-EM Environmental Micro-Vibration Detection Analyzer is specifically designed for measuring micro-vibrations in factory environments, helping users find the most suitable installation location effectively.

Feature Description

Long-Term Measurement and VC Curve Comparison

There are many factors that cause micro-vibrations in the environment,

and some of them occur only for a very short duration.

Therefore, long-term measurement is necessary to identify the causes of vibration.

The VMS®-EM Environmental Micro-Vibration Detection Analyzer

supports long-term measurement of environmental micro-vibrations

for up to 3 hours. It averages vibration velocity spectra every 10 seconds

and compares them with the VC curve.

The software includes a VC curve classification reference table,

allowing users to easily understand the current environmental vibration level.

Feature Description

Low-Frequency Dynamic Spectrum Peak Tracking

Within a factory, numerous machines and equipment operate simultaneously,

generating low-frequency vibrations that are difficult to filter during measurement.

The VMS®-EM Environmental Micro-Vibration Detection Analyzer

features a low-frequency dynamic analysis function,

which averages vibration values every 5 seconds and plots the spectrum peak variations.

This allows users to easily compare results and effectively measure vibration states

even in complex background environments.

Feature Description

Portable Measuring Device for Instant Measurement & Storage

The VMS®-EM Environmental Micro-Vibration Detection Analyzer

is a portable measuring device that allows users to easily carry and measure anytime.

It simplifies complex measurement operations and data conversion,

and users can create project folders as needed for better data organization.

It can also be used for pre-measuring environments before installing new precision equipment in the factory.

Based on the measurement results, users can plan the equipment placement,

preventing unnecessary relocations that may cause damage.

Precision Equipment

Environmental Testing

Designed for detecting micro-vibrations in high-tech factory environments and pre-installation testing of precision equipment. Allows users to pre-check if the environment is suitable, preventing increased costs due to poor equipment performance caused by environmental vibrations.

Function Description

UI Feature Screens

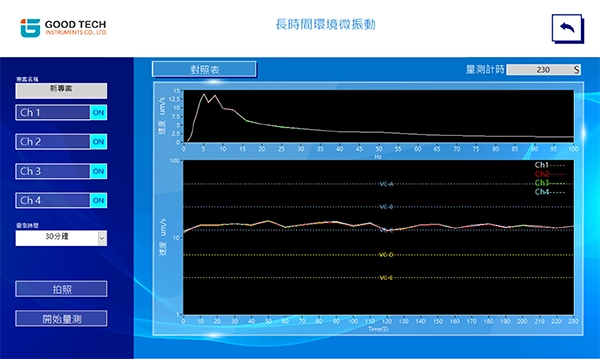

Long-Term Environmental Micro-Vibration

The VMS®-EM Environmental Micro-Vibration Detection Analyzer features long-term environmental micro-vibration measurement, with selectable measurement durations of 30 minutes, 1 hour, 2 hours, or 3 hours. It averages vibration velocity spectra every 10 seconds and compares them with the VC curve. The software includes a VC curve classification reference, allowing users to better understand the current environmental vibration level.

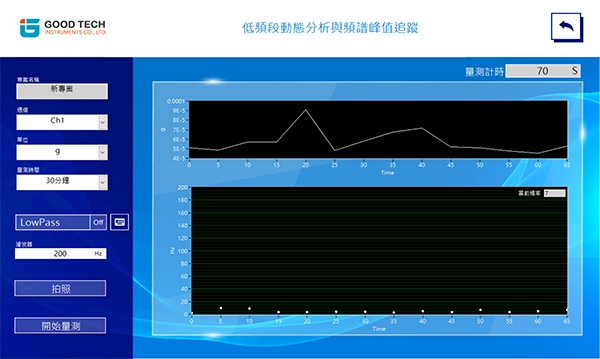

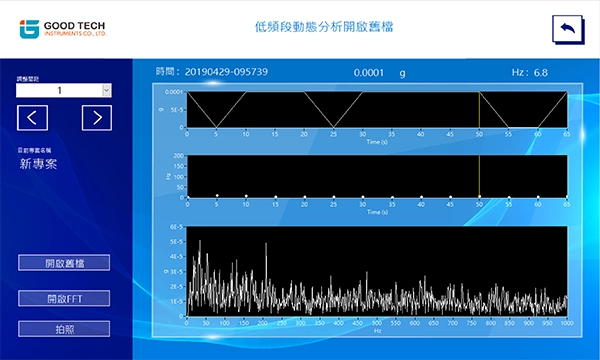

Low-Frequency Dynamic Analysis & Spectrum Peak Tracking

In factory environments, numerous machines and equipment operate simultaneously, generating low-frequency vibrations that are difficult to filter during measurement. The VMS®-EM Environmental Micro-Vibration Detection Analyzer features a low-frequency dynamic analysis function, which averages vibration values every 5 seconds and plots the spectrum peak variations. This allows users to easily compare results and effectively measure vibration states even in complex background environments.

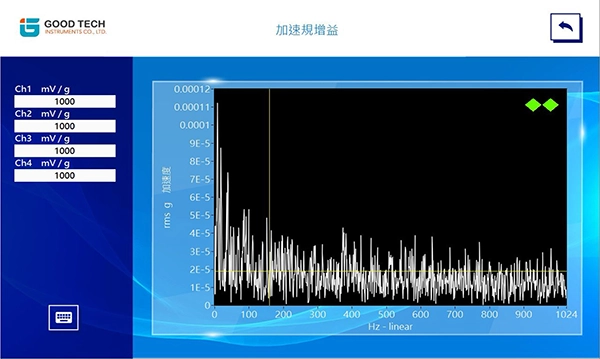

Accelerometer Gain

The VMS®-EM Environmental Micro-Vibration Detection Analyzer software includes a built-in accelerometer gain feature, allowing users to easily calibrate the accelerometer. The operation is simple—just select the input channel connected to the accelerometer, enter the sensitivity value, and the software will instantly calculate the spectrum for calibration comparison with the calibrator.

Applications

Fields and Scope

01. Micro-vibration measurement and analysis for high-tech factory construction sites

02. Floor micro-vibration measurement and analysis during various stages of high-tech factory construction

03. Micro-vibration measurement and analysis for precision equipment and vibration isolation bases

04. Diagnosis and measurement of floor micro-vibration issues

05. Diagnosis and measurement of precision equipment micro-vibration issues

06. Long-term micro-vibration measurement and monitoring

07. Structural dynamic characteristic testing and rigidity measurement

08. Structural vibration mode measurement and analysis

09. Vibration tests for foundation piles, trucks, high-speed rail, and trains

10. Pedestrian walking vibration tests

11. Floor vibration transmission tests

12. Vibration tests for Stocker, AGV, and Robot operations

13. Vibration tests for pumps and motor operations

14. Pipeline vibration tests

15. Press machine vibration, construction vibration tests

16. Earthquake vibration, construction vibration monitoring, and equipment vibration monitoring