What is Environmental Micro-Vibration?

FAQ | What is Environmental Micro-Vibration?When equipment operates, vibrations occur. This generally refers to vibrations caused by various factory equipment, as well as movement from workers or transport vehicles. External factors such as heavy vehicles passing by, construction pile-driving, wind forces, and even earthquakes can exert forces on buildings, leading to micro-vibrations.

What is Environmental Micro-Vibration?

What Type of Vibrations are Classified as Environmental Micro-Vibrations?

Poor Equipment Performance? Could Environmental Micro-Vibrations Be the Cause?

To prevent product defects caused by equipment performance issues, vibration standards have been established for building structures.

These standards not only ensure stability against tilting or collapse but also eliminate micro-vibrations that may affect equipment operation.

Vibrations can originate from internal sources, such as floor structures, machine operations, and factory noise,

or external factors, including vehicle traffic, nearby construction, and earthquakes.

Vibration Sources

What Are the Main Sources of Vibrations in Factories?

Internal Vibration Sources: Vibrations occur during equipment operation,

including those generated by various machinery, workers, and transport vehicles inside the factory.

External Vibration Sources: Heavy vehicles passing by, construction pile-driving,

wind forces, and earthquakes can exert forces on buildings, causing micro-vibrations.

The continuous development of advanced manufacturing processes is a top priority for major semiconductor companies.

While extensive R&D efforts contribute to progress, investments in precision manufacturing equipment and measurement tools

are crucial. These high-precision instruments require an optimal environment to function effectively.

Vibration-related issues have become a significant challenge in integrating advanced processes,

making vibration management a key factor in planning new semiconductor plants.

Environmental Micro-Vibrations

Why Should Factories Pay Special Attention to Environmental Micro-Vibrations?

Equipment performance can be affected by environmental vibrations, and the required vibration tolerance

varies based on the precision demands of different machines. Generally, higher-precision equipment has stricter requirements.

Examples include atomic force microscopes, electron microscopes, high-magnification optical microscopes,

semiconductor lithography machines, and optical module manufacturing.

External vibrations can significantly impact their performance and final product quality.

If factory vibration conditions fail to meet the specified requirements of precision equipment,

production yield rates may drop, and measurement instruments may struggle to achieve higher magnifications

needed for fine-linewidth detection, hindering advanced process development.

Installing precision vibration isolation equipment—both active and passive vibration isolation systems—

is now recognized as a critical factor in maintaining high wafer production yields.

What Type of Vibrations Are Considered Environmental Micro-Vibrations?

Micro-vibrations generally refer to vibrations within a frequency range of **2–100 Hz** and an amplitude

below **50 μm/s**. Vibration sources may stem from internal factory elements such as flooring strength,

machine operations, and noise, as well as external influences like traffic, nearby construction, and seismic activity.

What Vibration Standards Apply to Factory Environmental Micro-Vibrations?

To prevent product defects caused by environmental vibrations, international vibration standards have been

established for building structures. These guidelines not only ensure structural stability but also minimize

micro-vibrations that could affect equipment performance. The **ISO-10816** series outlines mechanical vibration

standards, while various **Vibration Criteria (VC)** classifications have been proposed based on different

equipment requirements, as illustrated below:

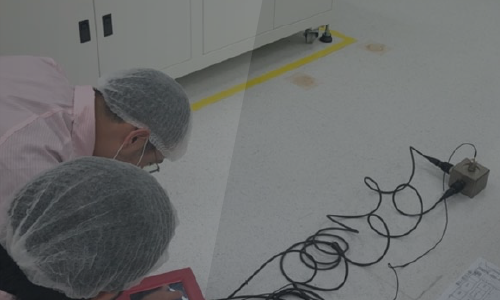

Vibration Measurement Services

Vibrations in laboratories or factories can directly or indirectly affect precision instruments.

Minor vibrations may cause errors in experimental data, while severe cases can lead to equipment damage,

resulting in significant losses.

**Gude Technology** offers professional vibration measurement services to identify the sources

of environmental and machine vibrations. This helps prevent negative impacts on experiments and manufacturing processes.

Additionally, vibration analysis of motors and rotating machinery enables predictive maintenance,

allowing businesses to optimize spending and enhance productivity and efficiency!

Regulation Overview

Applicable Vibration Standards for Factory Environmental Micro-Vibrations

To prevent product defects caused by equipment performance issues, vibration standards have been established for building structures. These standards not only ensure stability against tilting or collapse but also eliminate micro-vibrations that may affect equipment operation. The International Organization for Standardization (ISO) has developed a series of mechanical vibration standards, including **ISO-10816**. Additionally, researchers have proposed vibration standards known as **Vibration Criteria (VC)**, which define different vibration levels based on equipment requirements. The classification is as follows:

| Vibration Standard | Max Vibration Value μm/s (rms) |

Processing Size (μm) | Recommended Application Environment |

|---|---|---|---|

| Office | 400 (84dB) | None |

|

| General Industrial Zone | 800 (90dB) | None |

|

| Residential Area (Daytime) | 200 (78dB) | 75 |

|

| Operating Theatre (ISO) | 100 (72dB) | 25 |

|

| VC-A | 50 (66dB) | 8 |

|

| VC-B | 25 (60dB) | 3 |

|

| VC-C | 12.5 (54dB) | 1 |

|

| VC-D | 6.25 (48dB) | 0.3 |

|

| VC-E | 3.125 (42dB) | 0.1 |

|

As the semiconductor industry advances into nanometer-scale processes, additional vibration standards such as **NIST-A** and **NIST-A1** have been introduced. These standards primarily address deficiencies in VC criteria in the **low-frequency range**.