How to Ensure the Stability of Coating Equipment in the Coating Process?

Case|How to Ensure the Stability of Coating Equipment in the Coating Process?In semiconductor processes, abnormal vibrations during coating deposition can lead to uneven coating. How can equipment measurement help verify process stability?

Coating Methods

Coating methods can generally be categorized into dry coating and wet coating. Wet coating, which does not require a vacuum environment, is more suitable for mass production and is widely used in industrial applications. The coating liquid is evenly applied to the substrate, followed by a drying and curing process to form a solid thin film.

Principle of Spin Coating

Spin coating is a wet coating process where a substrate (such as a silicon wafer or other smooth object)

is held in place by vacuum suction. The coating liquid is dispensed at the center of the object, and centrifugal force

from spinning evenly distributes the liquid across the surface, expelling excess liquid to form a thin film.

Factors such as rotational speed, spin duration, and drying rate affect the thickness of the formed film.

If the equipment experiences abnormal vibrations during the process, it can lead to uneven coating.

Solution and Monitoring Explanation

VMS-PH Dynamic Quality Analysis Instrument

Using the dynamic analysis features of VMS-PH, we can measure the operating status of the coating machine

and the nozzle rotation speed. By comparing vibration signals at different speeds,

we can determine process stability. The system can monitor and diagnose individual operations,

helping to identify anomalies or unstable conditions early, enabling predictive maintenance to avoid unexpected failures.

Measurement Conditions

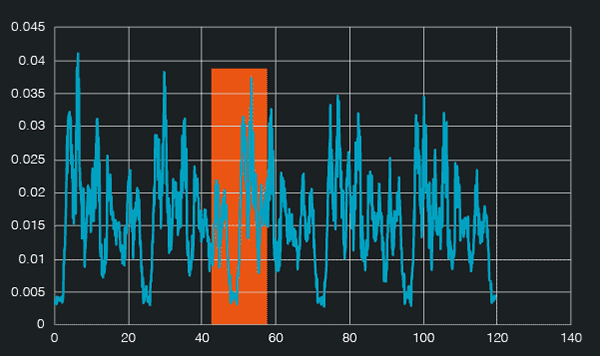

1. Comparison of Acceleration and Deceleration Performance of Coating Machine STAGE

• Measurement Position: Parallel to the STAGE movement direction on the marble table.

• Measured Machine: 001

• Measurement Method: Compare dynamic performance at process speeds of 80 and 120.

• Test Objective: To analyze differences in acceleration and deceleration.

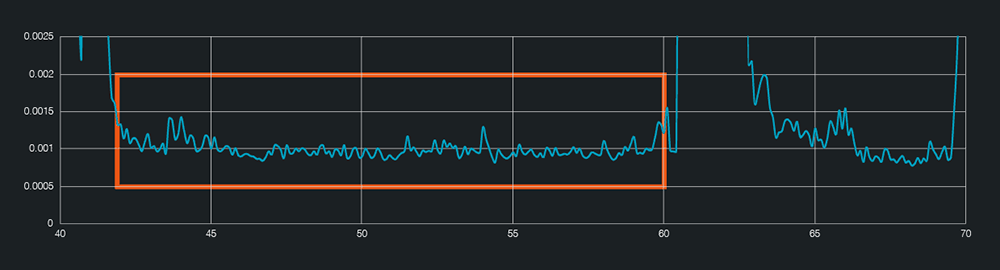

Speed 80

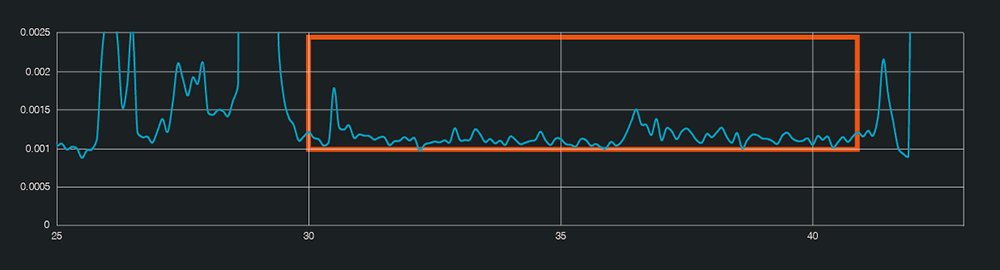

Speed 120

At process speed 120, the coating dynamic signals are higher than at speed 80.

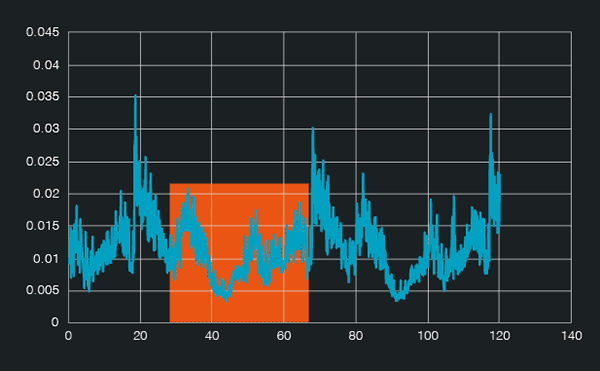

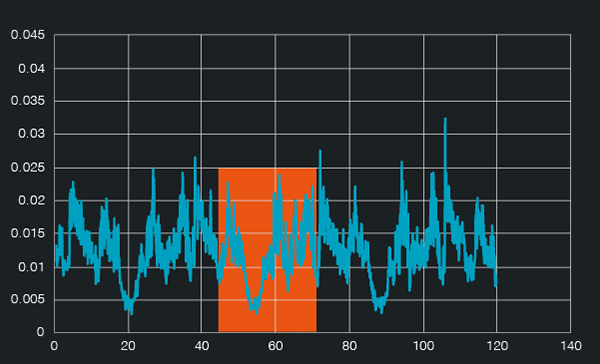

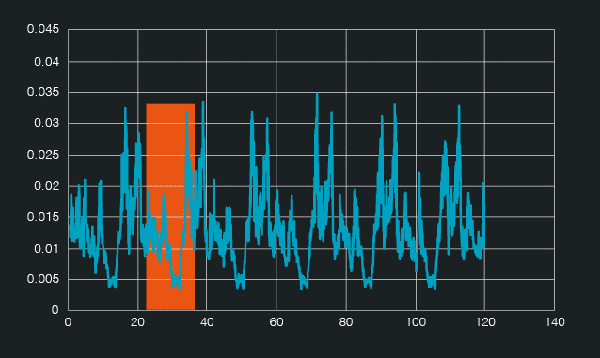

2. Comparison of Nozzle Operation at Different Speeds

• Measurement Position: Magnetic attachment at the vertical position of the nozzle rail.

• Measured Machine: 002

• Measurement Method: Compare operation at speeds of 80, 120, 180, and 240.

• Test Objective: To analyze acceleration and deceleration differences.

Speed 80

Speed 120

Speed 180

Speed 240

Measurement Conclusion

The VMS-PH dynamic analysis function compares the dynamic signal results of target machine operations, allowing early detection of small changes caused by instability, wear, aging, damage, or resonance. This enables predictive maintenance to prevent unexpected failures.

VMS-PH Equipment Dynamic Quality Analyzer