Visible Vibrations on the Melt Surface of the Crystal Growth Furnace – How to Identify the Source?

Diagnostic Achievements|Visible Vibrations on the Melt Surface of the Crystal Growth Furnace – How to Identify the Source?The wafer is the most critical material in semiconductor integrated circuit manufacturing. How to diagnose crystal growth furnaces and prevent abnormal vibrations that may lead to defective crystal seed formation?

Crystal Growth Furnace and Wafers

Wafer

Wafers are the most crucial materials in semiconductor manufacturing. Various factors affect crystal seed formation quality. The Czochralski process is used to melt polysilicon, with a small silicon seed crystal introduced into the melt and slowly pulled out to form a cylindrical single crystal silicon ingot. This process, known as "crystal growth," can be disrupted by abnormal vibrations, leading to poor purity, uneven impurity distribution, and abnormal growth.

Solution and Monitoring Description

VMS-PH Equipment Dynamic Analyzer

Investigation Focus: Identifying the cause of melt surface vibrations and designing a data-driven control method.

Detection Method: Comparing vibration data from furnace 1 (abnormal) and furnace 2 (normal) to identify possible vibration sources.

Instrumentation: Using the VMS®-PH dynamic quality analyzer to measure vibration near the crucible.

Optimization Process: Digitizing vibration data to support future process quality control.

Measurement Status

How to Monitor Abnormal Vibrations in the Crystal Growth Furnace

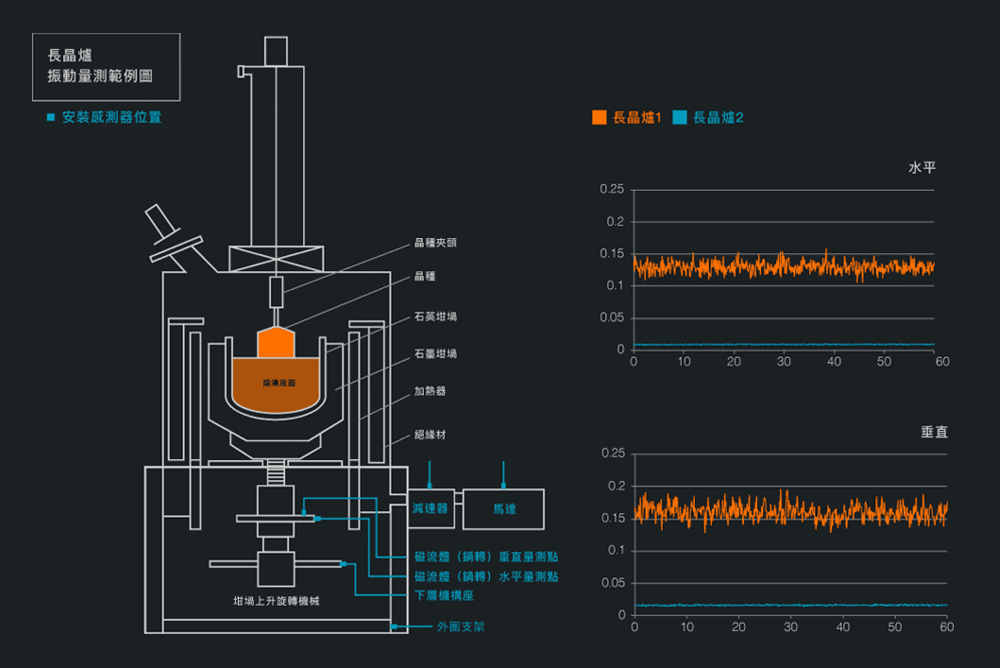

Identifying vibration sources in the furnace using the VMS®-PH dynamic quality analyzer by comparing the normal and abnormal furnaces. Sensors were installed at suitable measurement points (as shown below). Results indicate that both horizontal and vertical vibrations in Furnace 1 are significantly greater than Furnace 2, confirming visual observations. The data can serve as a benchmark for future vibration monitoring.

Vibration Source Investigation Analysis

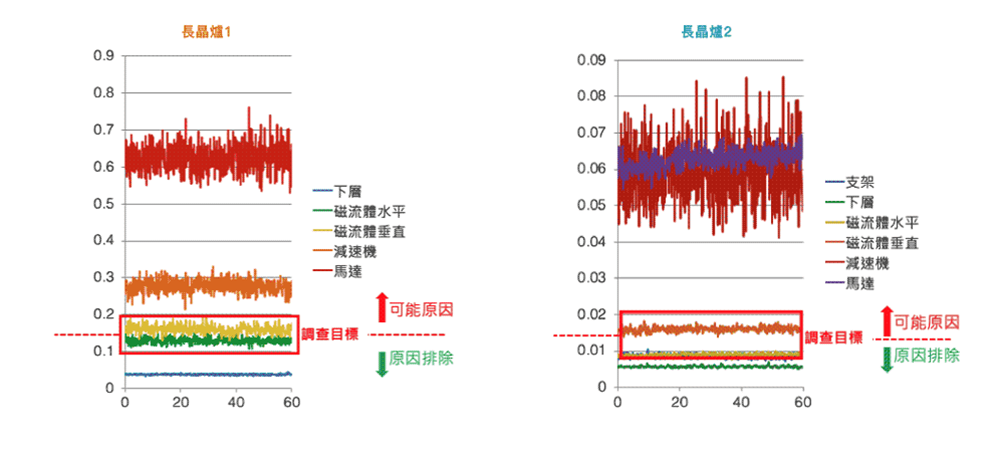

Vibration analysis showed that lower structure vibrations were minimal, ruling them out as the source. Measurements of furnaces 1 and 2 confirmed that the motor and gearbox vibrations were the primary contributors.

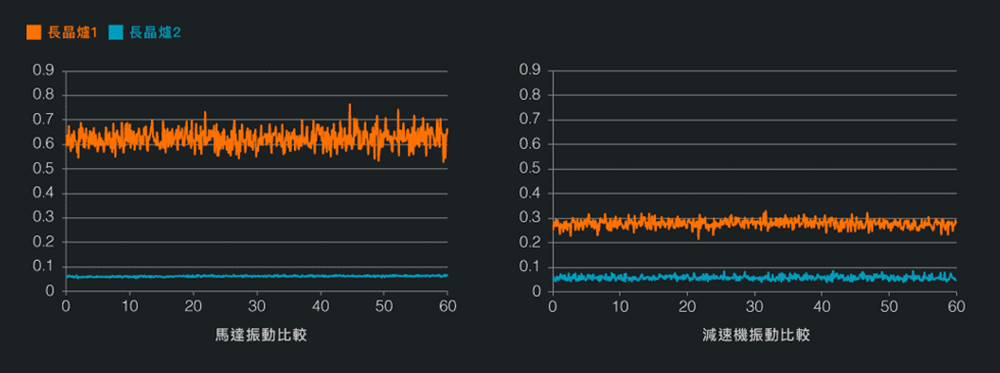

Motor and Gearbox Measurements

In Furnace 1, the motor vibrations were significantly higher than those in Furnace 2, indicating a potential issue with the motor, which transmits vibrations to the gearbox and eventually affects the melt surface.

Measurement Conclusions

Vibration Source:

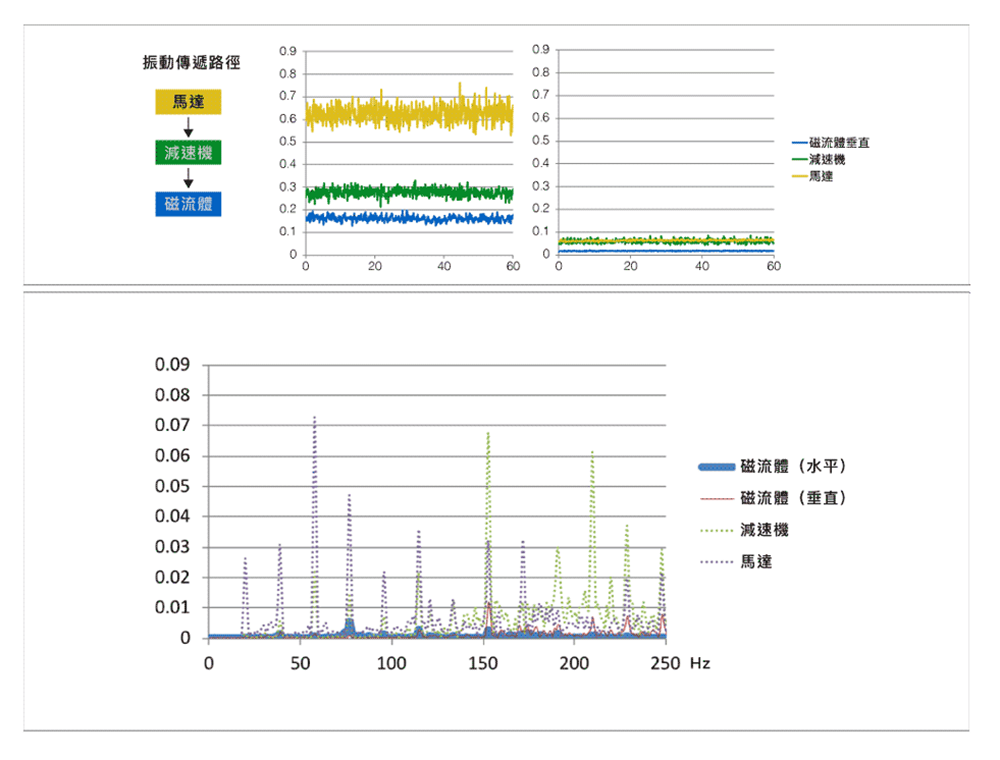

Frequency Spectrum Analysis: The vibration path is identified as Motor > Gearbox > Magnetic Fluid. Future analysis should monitor the relationship between these components to detect potential failures.

Maintenance Recommendations

It is recommended to prioritize maintenance or replacement of the motor to reduce melt surface vibration. A high-quality motor can minimize wear on other equipment components.

The VMS®-PH Equipment Dynamic Analyzer helps establish data-driven standards for vibration control, enabling early issue detection and improving production efficiency.

VMS-PH Equipment Dynamic Analyzer