How to Prevent Poor Cutting Smoothness in Wire Cutting Machines for Crystal Rods?

Case | How to Prevent Poor Cutting Smoothness in Wire Cutting Machines for Crystal Rods?For cutting processes requiring minimal warping, uniform thickness, and reduced kerf loss, how can machine conditions be effectively managed to optimize cutting efficiency and prevent losses caused by equipment issues?

Wafer Processing

Wafer cutting is a critical step in semiconductor processing, significantly affecting wafer yield and quality. Common cutting machines include outer diameter saws, inner diameter saws, and wire cutting machines. Regardless of the type, the cutting tool is a key factor. For instance, in wafer outer diameter cutting, if the blade cannot withstand the pressure from the crystal, deformation and lateral movement may occur, resulting in uneven cuts and increased crystal loss.

Solution and Monitoring Explanation

Wafer Cutting

Detect Mechanical Issues Early?

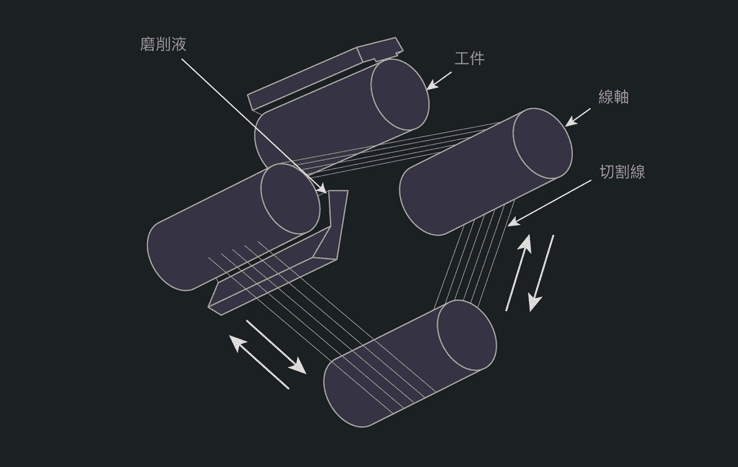

Wire cutting machines are primarily classified into three-axis and four-axis types.

The quality, precision, efficiency, and yield of wafer cutting are closely related to the performance of the cutting blade,

the cutting wire, installation methods, and tensioning techniques. Wire cutting is a free grinding process,

where diamond microparticles are plated onto the cutting wire. The wire spool is grooved according to the required wafer thickness,

and the cutting wire is wound around the spools. During operation, the input and output spools rotate at high speed,

guiding the crystal rod into the cutting zone. Assisted by cutting fluid, the process is completed with high precision.

Measurement Conclusion

During the cutting process, tool wear from high-speed operation or damage to the cutting wire and blade can significantly increase silicon wafer loss rates. Therefore, machine monitoring is essential to detect mechanical issues early. If abnormalities occur in the product, measurement data can be used for retrospective analysis to determine the root cause of the issue.