What is SOA?

FAQ|What is SOA?SOA (Spectrum Overall Value) distinguishes valid signals from environmental system noise. Its specialized algorithm suppresses noise for a clearer and more efficient resolution.

Feature Description

Early Fault Detection is 4 Times More Effective

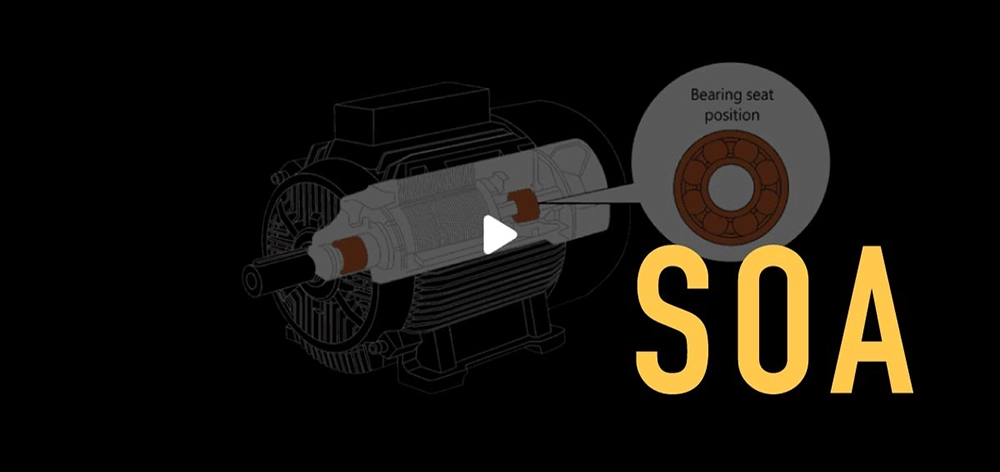

SOA (Spectrum Overall Value)

Good Tech's SOA value differs from traditional OA values on the market. SOA distinguishes valid signals from environmental system noise. Its specialized algorithm suppresses noise for a clearer and more efficient resolution, making early fault detection 4 times more effective than other market algorithms.

SOA value management tendencies:

- Same Machine Comparison - Baseline values: Normal: NA; Warning; Danger.

- Same Type Comparison - Machines of the same model under identical installation and operating conditions.

- Standard Comparison - Utilizing commonly adopted domestic and international standards for setting warning and danger thresholds.

Principle Explanation

Users Can Easily Understand Changes in Vibration Characteristics

OA Value:

The OA value refers to the overall level of a full frequency bandwidth or a specific frequency band (Band).

The Overall Value is used to measure the total energy in a signal, representing the relationship between total energy and time or rotational speed.

The calculated OA value may vary depending on different software.

Rotor Quality:

Vibration analysis is conducted based on internationally recognized ISO standards. The results are displayed in green, yellow, orange, and red.

After completing the rotor quality measurement function (ISO 10816 Class 1 Management Analysis),

users can perform appropriate maintenance or repairs based on recommendations for orange and red areas.

If results remain in the green or yellow zones, it will trigger Class 2 Management Measurement.

Class 2 management includes two critical functions: Vibration Anomalies and Feature Diagnosis.

Both are equally important, and if either test result is abnormal, it is best for the equipment user to arrange repairs immediately.

Vibration Anomalies:

According to ISO standards, each machine has its own vibration tolerance threshold.

A sudden increase in vibration levels during operation is a warning sign of machine failure, which should not be ignored by equipment users.

The rotor health monitoring system detects and establishes a vibration anomaly baseline using the VRMS value (within green and yellow zones).

It further evaluates vibration increments, with the system’s specialized algorithm using ISO 10816 as a standard for determining results.

Feature Diagnosis:

For many types of mechanical equipment, vibration measurements provide values that reflect equipment status.

In frequency spectrum analysis, we can easily identify abnormal characteristics of the equipment.

By quantifying spectrum vibration values, we derive an overall intensity value known as **SOA**—an unlimited quantification of spectrum values.

By monitoring SOA changes, users can effortlessly understand variations in vibration characteristics.

Implementation Benefits

How to Quickly Manage Equipment Efficiency

Solve Wiring Issues and Maintain Continuous Monitoring

In traditional manual inspection mechanisms, it is often challenging to conduct comprehensive monitoring due to inaccessible equipment locations or high-risk environments (such as high temperatures or elevated areas).

The RM-IOT-B Wireless Rotor Health Monitoring System (Battery-Powered) uses a LoRa LPWAN wireless receiver with a transmission range of 500-800 meters (depending on the configuration of on-site obstacles). A single wireless receiver can support up to 500 wireless sensors.