Custom-Tailored for Specific Equipment and Functions

Why is it necessary?

The growing need for additional monitoring systems

Regular inspection needs in equipment manufacturing? There are various types of precision equipment in factories, and the internal components of these systems operate in complex workflows. When abnormalities occur, multiple issues often arise simultaneously. While most precision equipment comes with built-in monitoring systems from manufacturers, converting equipment data into usable resources for production line optimization and accurately diagnosing and resolving abnormalities remains a challenging task. This has led to an increasing need for additional monitoring systems.

Problem Solving

Common Issues in Equipment Monitoring Systems

Equipment Condition Limitations

Data Storage Issues

Software Operation Difficulties

Alarm Requirement Mismatch

Unclear Visibility

Insufficient Development Budget

When factory or production line engineers attempt to install additional monitoring systems,

they often encounter issues such as the equipment manufacturer not providing data

or differences in programming making data extraction impossible.

Additionally, monitoring systems may have too many complex features, making them difficult to operate.

In some cases, alarm settings may not match actual needs, causing confusion among users,

while unclear data interfaces make it difficult to interpret the results.

With so many monitoring systems on the market, how do you choose the right one?

Are all the features of a monitoring system truly necessary for the user?

Factory automation equipment is a significant investment—how can users find an optimal monitoring solution

that fits within a limited budget while meeting their specific needs?

Feature Overview

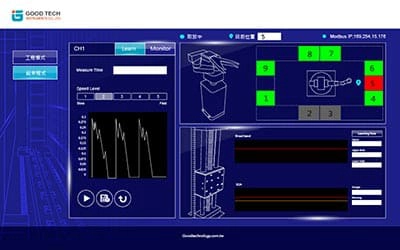

Real-Time Online Monitoring & Measurement Functionality

OLVMS®-M SERIES Customized Monitoring System is designed to monitor critical core equipment in factories. It is developed based on user needs, allowing for flexible monitoring system planning and the ability to gradually expand based on budget constraints. Not only does it provide measurement data, but it also incorporates a series of algorithms, allowing on-site measurement results to be instantly analyzed and converted into actionable assessments.

Feature Overview

Dynamic Equipment & Steady-State Environmental Data

OLVMS®-M SERIES Customized Monitoring System is equipped with powerful measurement and analysis capabilities tailored to factory-specific needs. It enables real-time measurement and monitoring, allowing for instant detection of equipment issues. Additionally, the system provides various analytical data that help process developers design more refined manufacturing processes and parameters.

Feature Overview

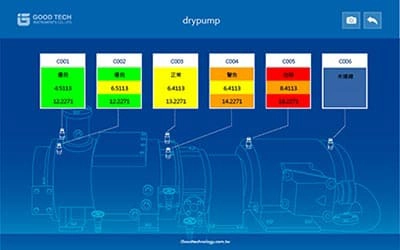

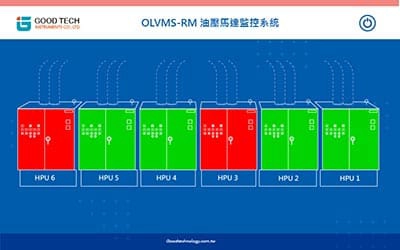

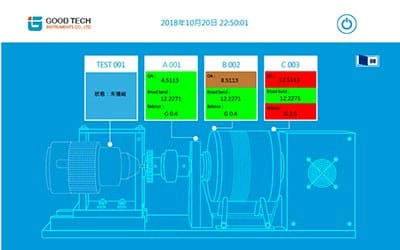

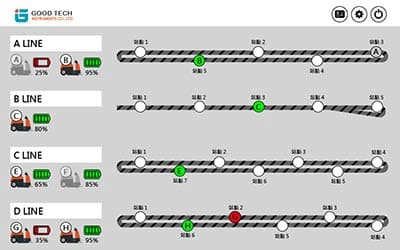

Factory Equipment Customized Interface

With numerous monitoring systems in a factory, it is essential to maintain a unified format or corporate-branded visual interface. OLVMS®-M SERIES Customized Monitoring System allows for a fully tailored user interface and color scheme based on factory-specific requirements.

Feature Overview

Judgment Results & Customizable Threshold Standards

OLVMS®-M SERIES Customized Monitoring System integrates industry standards and relevant ISO regulations based on the attributes of the measured equipment, allowing users to easily establish a health management database for their machines. The system provides broad initial result assessments and, depending on measurement functionalities, enables users to define their own monitoring criteria and threshold values.

Feature Overview

Smart Trend Analysis & Prediction System

OLVMS®-M SERIES Customized Monitoring System collects large amounts of data and converts them into graphical analyses, allowing users to clearly understand the real-time status and stability of the production line. Depending on the manufacturing process and equipment characteristics, AI-powered learning and computational functions can be integrated to help users establish their own equipment health management standards and predict equipment failure timelines.

Feature Overview

Alarm Notifications & Online Monitoring System

OLVMS®-M SERIES Customized Monitoring System detects abnormal equipment status and sends alarm notifications to relevant personnel. Alerts are displayed on the system interface, and notifications can be set up via LINE, email, or external buzzer integration.

Customized

Quality Control

OLVMS®-M SERIES Customized Monitoring System is designed to meet specific factory requirements, providing real-time measurement and monitoring to quickly identify equipment issues. By utilizing various analytical data, process developers can design more refined manufacturing processes and parameters.

Performance Cases

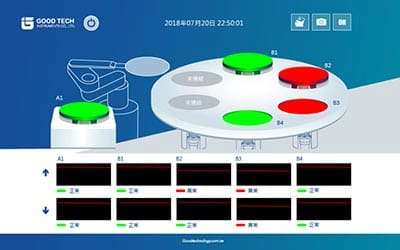

Customized UI Implementation

Core Rotor Equipment

OLVMS®-M SERIES Customized Monitoring System provides tailored monitoring solutions for various rotor-based equipment, integrating optimal monitoring processes. It is designed to support real-time online reporting of factory equipment issues as well as long-term equipment monitoring.

Monitoring Critical Equipment

OLVMS®-M SERIES Customized Monitoring System provides tailored monitoring solutions for various rotor-based equipment, integrating optimal monitoring processes. It is designed to support real-time online reporting of factory equipment issues as well as long-term equipment monitoring.

Equipment Monitoring / Dedicated Control Room

OLVMS®-M SERIES Customized Monitoring System is designed to create tailored monitoring processes based on specific needs and can be integrated with IoT to develop a dedicated control room.

Benefits

Tailored to Your Workflow – A True Customization!

With the rise of Industry 4.0 and smart manufacturing,

the demand for automated equipment has been increasing.

To maintain factory environments and equipment efficiently,

real-time monitoring and unified system integration are essential.

Good Tech, with years of experience in vibration measurement,

leverages edge computing technology to provide customized solutions

for factory equipment.

By transforming complex data collected from sensors into actionable insights,

while preserving the raw data for engineers to optimize production lines,

we help factories integrate systems efficiently.

Additionally, our software simplifies operations,

delivers only the most relevant decision-making results,

and offers a fully customizable UI tailored to factory needs.

OLVMS®-M SERIES Customized Monitoring System

helps users monitor specific equipment and functions precisely,

improving equipment stability, enabling predictive maintenance,

enhancing production yield and capacity, and extending equipment lifespan.

Avoid unexpected downtime of production line equipment

Enhance machine control and management capabilities

Significantly reduce maintenance and repair costs

Maintain product quality and production capacity

Easily collect machine data

Quickly diagnose failures and shorten downtime

Applications

Who Needs OLVMS®-M?

Maintenance & Repair

Engineers

Facility Monitoring

Engineers

Process Design

Developers

Precision Machinery

Users

Manufacturing Line

Managers

Factory Efficiency

Supervisors

Simply put, OLVMS®-M SERIES Customized Monitoring System allows maintenance engineers to monitor real-time machine health and predict the optimal timing for maintenance and component replacements.

With this system, facility monitoring engineers can ensure consistency and reliability in production line machine quality, while process design developers can leverage data-driven management to improve product yield and prevent unexpected downtime. Furthermore, it helps reduce the risk of severe machine damage and extends equipment lifespan.

OLVMS®-M SERIES Customized Monitoring System utilizes vibration measurement data to provide predictive maintenance insights. Precision machinery users can monitor their machines’ operating conditions in real-time and conduct early repairs. Manufacturing line managers can avoid unplanned production halts due to maintenance issues, and factory efficiency supervisors can effectively reduce operational costs for related enterprises.