Wafer Grinding Unevenness?

Case|Wafer Grinding Unevenness?During the grinding process, equipment abnormalities can lead to poor wafer flatness, rough surface finish, chamfering defects, and edge polishing defects. How can we prevent these issues?

Grinding / Polishing Processing

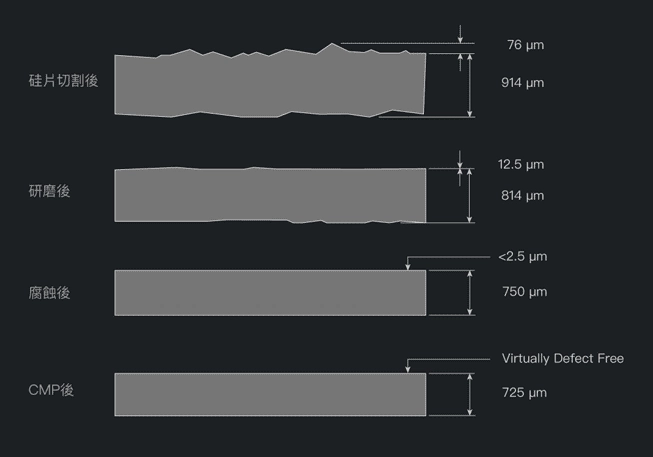

Before wafer grinding, a special protective film is applied to the backside of the wafer to ensure that the front IC is not damaged before proceeding with the grinding phase. Wafer grinding (Back Grinding) mainly involves grinding the wafer from the backside to control the thickness within an acceptable range. The purpose of polishing is to improve micro-defects left by previous processes, enhance wafer flatness, and prevent particle adhesion.

During the grinding process, the wafer thickness will also affect the final IC completion. For example, if the wafer is too thick, it can cause poor heat dissipation, while being too thin may lead to breakage. With the increasing demand for 12-inch wafers, the difficulty of grinding processes has also increased.

Solutions

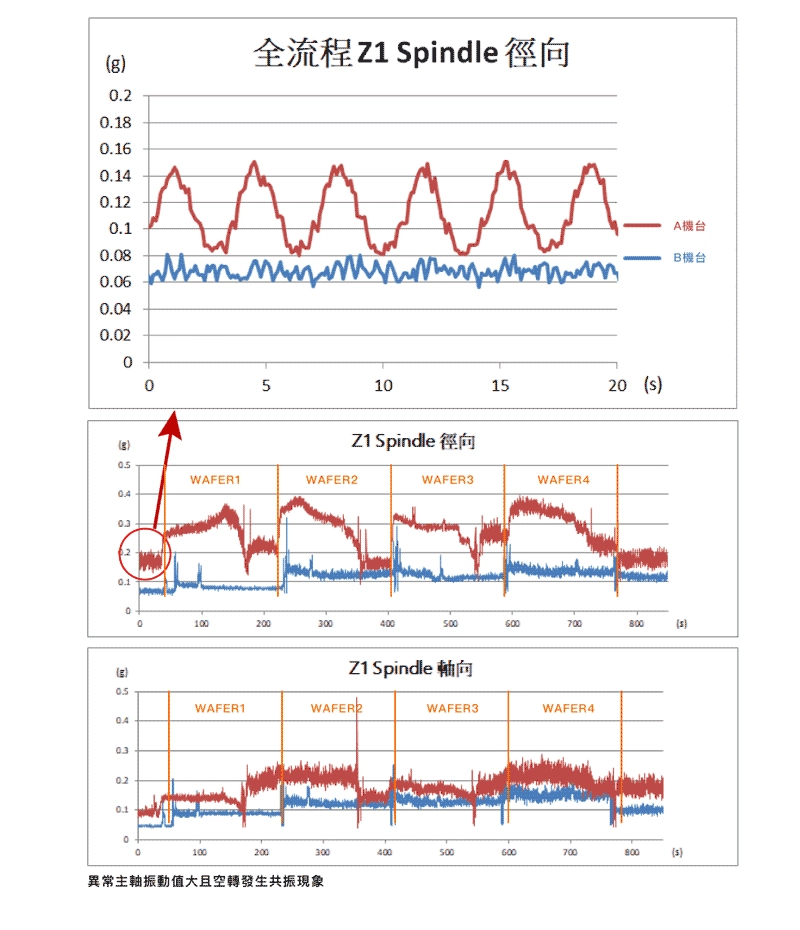

Grinding/Polishing machine quality monitoring helps determine the final wafer thickness and surface roughness. Excessive vibration signals during the process can lead to poor wafer flatness, rough surface finish, chamfering defects, and edge polishing issues. Through machine monitoring, mechanical issues can be detected early. If product anomalies are found, measurement data can be traced back to identify the root cause.

Measurement Conditions

As shown in the figure below, by measuring the dynamic vibration changes perpendicular to the wafer surface during grinding, it can be confirmed whether the wafer stress changes are influenced by equipment vibrations. When the rotary spindle malfunctions, excessive vibration values and resonance during idle operation can significantly increase wafer breakage rates.

Measurement Conclusions

The purpose of using wafer grinding/polishing machines is to remove micro-defects from previous processes, improve wafer flatness, and prevent particle adhesion. The wafer undergoes processes such as sawing, grinding, mechanical polishing, and chemical polishing.

Due to the high precision requirements of the equipment, during the grinding process, wafer breakage and scratches are common issues. Therefore, users need a comprehensive monitoring plan for the entire process to avoid losses caused by machine abnormalities.