Establish Machine Health Standards to Eliminate Defective Products

Why is it necessary?

Establishing Equipment Health Standards

What is Machine Learning?

In simple terms, machine learning is a process where a computer program accumulates data and, through specialized algorithms, autonomously analyzes, statistically processes, and makes decisions or classifications, even predicting outcomes. It helps users improve accuracy and enhance decision-making.

Machine learning is a subset of artificial intelligence (AI), which has historically focused on reasoning, knowledge, and learning. Machine learning is one of the approaches to achieving AI, using data-driven techniques to solve AI-related challenges.

In recent years, industrial equipment has relied on high-performance measurement technologies to improve product yield rates and production efficiency. Additionally, by collecting and analyzing large amounts of data, companies can enhance equipment performance. Therefore, the ability to autonomously assess equipment conditions and prevent unexpected failures has become a key topic for in-depth exploration.

The OLVMS®-ML Machine Learning Intelligent Monitoring System developed by GoodTech is designed for dynamic monitoring of various mechanical equipment. Users can easily establish health standards, and the system learns from accumulated data to perform statistical analysis and decision-making. This enables industries to implement predictive maintenance plans and assists designers in optimizing production line processes.

Problem Solving

Common Abnormal Behaviors in Machinery

Abnormal motor axis drive

Unusual mechanical vibration

Incorrect manufacturing process settings

Abnormal timing in machine operations

Mechanical wear and aging

Unexpected machine collision

Excessive external environmental vibrations

Abnormal machine angle

As factory production processes become increasingly precise, the demands on equipment operation behavior are also rising. By implementing the OLVMS®-ML Machine Learning Intelligent Monitoring System, companies can regulate proper equipment operations, detect anomalies, and resolve various equipment issues, ultimately enhancing production line efficiency and reducing costs.

Feature Description

For Periodic Production Equipment

The OLVMS®-ML Machine Learning Intelligent Monitoring System developed by Goodtech is designed for dynamic monitoring of periodic (repetitive) production equipment.

Users can easily establish health norms, allowing the system to learn from operational patterns, accumulate data, perform statistical analysis, and make informed decisions.

This enables industries to establish predictive maintenance plans and helps designers optimize production line workflows.

Unlike conventional measurement instruments with single-function usage, the OLVMS®-ML Machine Learning Intelligent Monitoring System can autonomously learn and record complex mechanical movements,

assess equipment health, and predict various complex dynamic behaviors such as potential mechanical failures, aging, and misalignment.

Fast Learning

Quickly select target signals and establish learning operations.

Instant Measurement

Fast installation regardless of pre- or post-equipment setup.

Automatic Identification

Real-time recognition of actions and accurate cycle extraction.

Multi-task Detection

Executes multiple identification algorithms simultaneously.

Intelligent Computing

Provides AI-powered calculations for data reference.

Result Display

Alerts can be integrated with external I/O output.

Feature Description

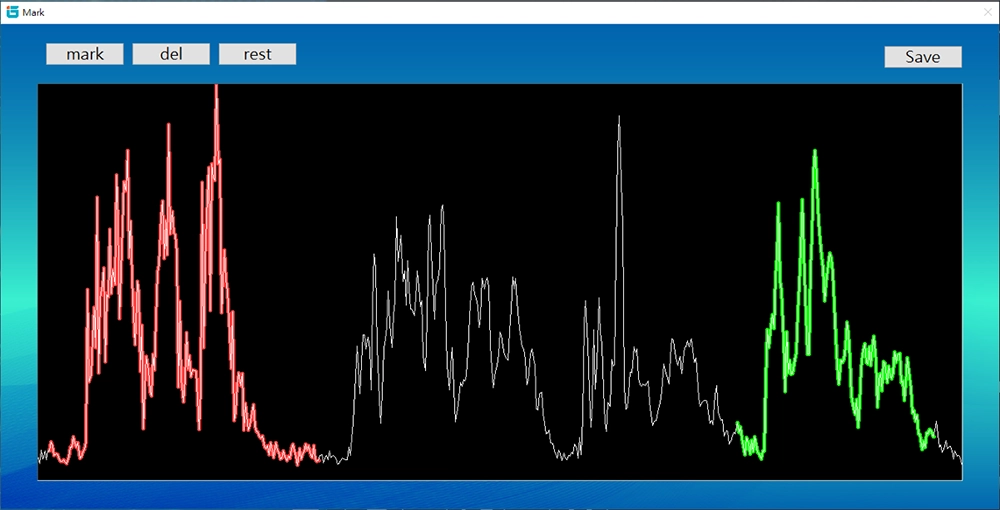

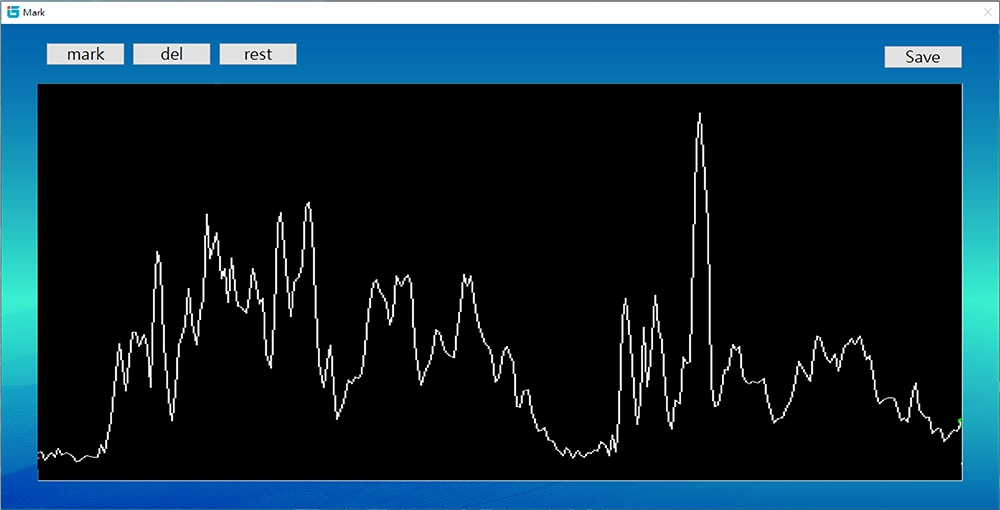

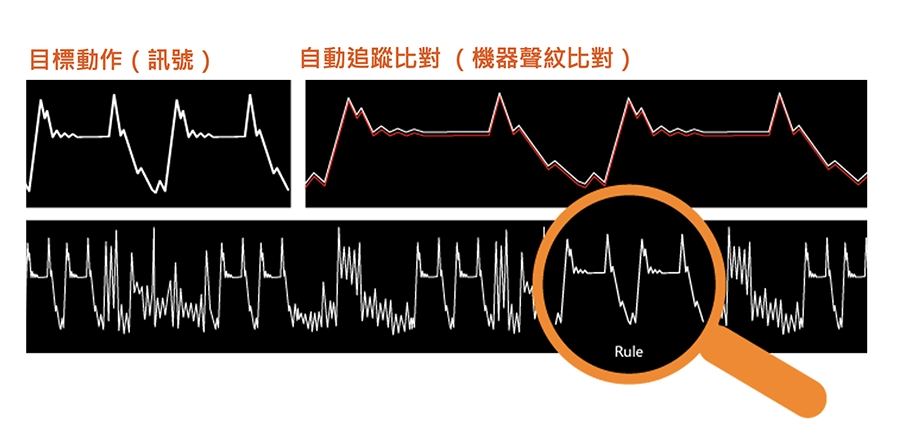

Transfer Human Experience, Rapidly Learn Target Motion Cycles

The OLVMS®-ML Machine Learning Intelligent Monitoring System allows users to design customized health state patterns for inspection.

It enables real-time and rapid learning (calibration) of repetitive or semi-repetitive production behaviors,

transforming human experience into a rule-based monitoring system.

By learning accurate machine motion signals, the system retains only the critical segments for monitoring,

avoiding unnecessary signal collection and focusing solely on key areas.

It performs production quality monitoring tasks without requiring direct machine handshake.

The system learns different mechanical motion scenarios, and when the machine performs various operations,

it automatically compares real-time signals with its model library, identifies matching signals, and applies the appropriate monitoring model.

Built-in Monitoring Models: Vibration, Frequency, Phase, Wavelet, Standard Deviation, Stability, and other algorithms.

Feature Description

Automatically Track Target Processing Signals and Identify Results in Real-Time

The system learns and records different machine operation models. When a machine performs various actions, it automatically compares real-time signals with its model library, identifies matching signals, and uses the corresponding model for monitoring. Even if mechanical anomalies or external interferences occur during the manufacturing process, the automatic tracking and recognition technology can still accurately determine whether the data signals belong to the same cycle operation and classify the results accordingly.

Machine Acoustic Fingerprint Matching

Machine acoustic fingerprint matching refers to a technology that analyzes and compares unique acoustic

characteristics within sounds to verify or identify an entity. Similar to human fingerprints, every

individual's voice has unique characteristics such as frequency, pitch, speed, and pronunciation style,

forming a distinct "voice fingerprint." By collecting the dynamic signals of machines, we can treat them

as acoustic fingerprints, each possessing unique properties.

In simple terms, automatic tracking and recognition technology extracts dynamic features from signals,

including spectral characteristics, vibration patterns, and dynamic changes. These features are then used

in a matching algorithm to determine whether the detected signal belongs to the required dynamic signal.

Built-in monitoring models: Vibration, Frequency, Phase, Wavelet, Standard Deviation, Stability, and other algorithms.

Feature Description

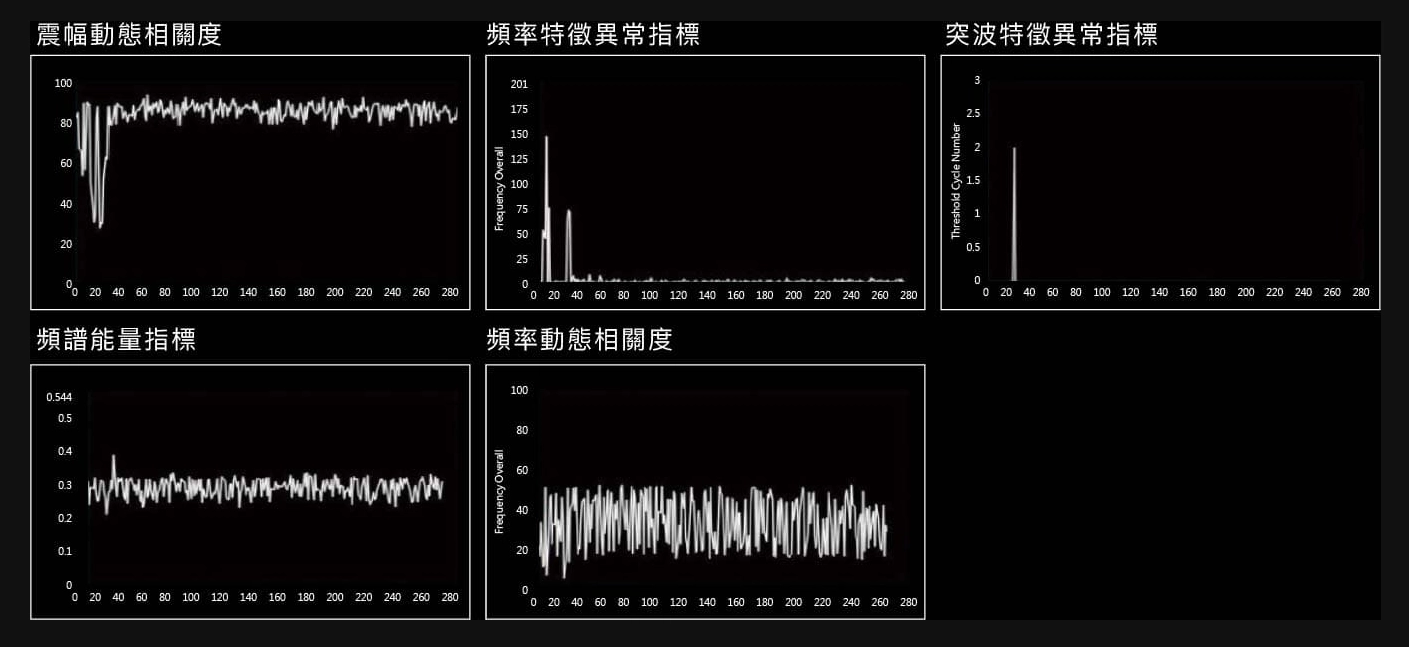

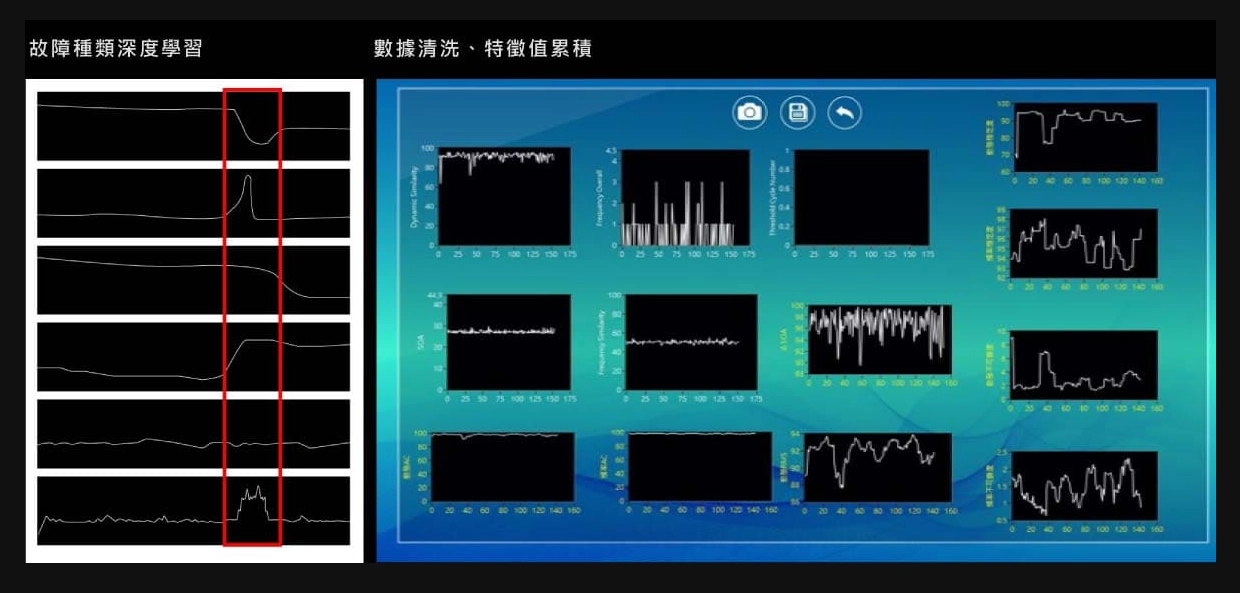

Waiting for Anomalous Events & Machine Feature Recognition Accumulation Technology

Amplitude Dynamic Correlation: Describes the stability of periodic manufacturing operations. A downward trend indicates equipment instability and potential degradation.

Frequency Feature Anomaly Index: Indicates the level of abnormal frequencies generated internally or externally within the manufacturing process.

Spike Feature Anomaly Index: Describes the degree of abnormal spikes occurring internally or externally within the manufacturing process.

Spectral Energy Index: Describes the stability of various moving parts and structures within the manufacturing process.

Frequency Dynamic Correlation: Describes the frequency stability of periodic manufacturing operations. A downward trend indicates equipment instability and degradation.

The classification of processing behaviors and manufacturing process types has already been completed, allowing a clean process database to be directly incorporated into event execution training.

Transfer Human Experience ⮕ Real-time Monitoring ⮕ Trend Management ⮕ Data Cleaning ⮕ AI Integration

Feature Description

Provides AI Calculation Parameters and Integrates with Trend Graphs

The OLVMS®-ML Machine Learning Intelligent Monitoring System adopts a high-performance measurement approach,

learning dynamic mechanical signal behaviors while providing AI computational parameters.

Product developers and testing personnel can utilize this data for validation and verification, helping to

optimize production line design and processes.

As AI technology rapidly advances in the era of Industry 4.0, various industrial demands, such as managing

complex machine operations, simplifying production processes, increasing productivity, and maintaining product

quality, become increasingly important. By leveraging AI-powered high-performance measurement systems, various

equipment issues can be efficiently resolved. Additionally, deep learning, a subset of AI technology, enables

machines to process large amounts of data through specialized algorithms, allowing them to learn, analyze, and

predict future trends.

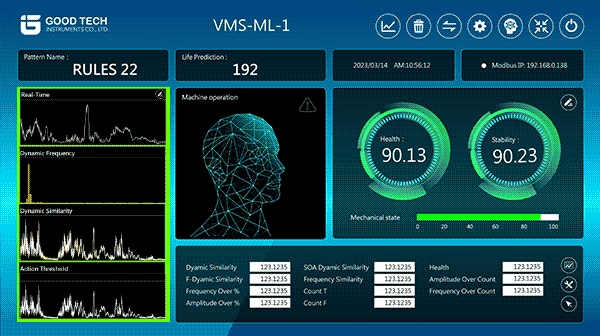

Motion Similarity Score

Dynamic Frequency Similarity Score

Average Amplitude Score in Motion Cycle

Spike Count Score in Motion Cycle

Continuously Optimized

Measurement System

The OLVMS®-ML Machine Learning Intelligent Monitoring System is a cutting-edge measurement system for industrial machinery, surpassing all other available solutions on the market. It is continuously optimized through customer feedback to enhance its software capabilities.

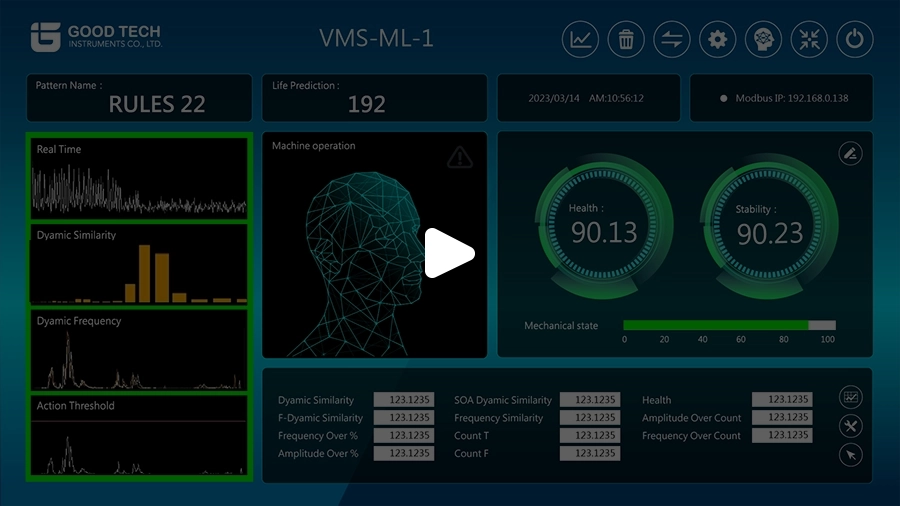

UI Function Screen

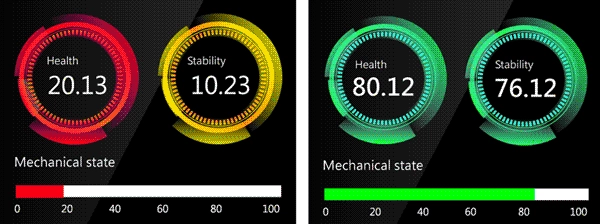

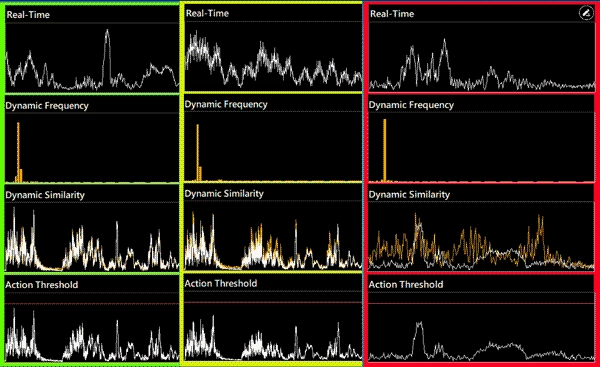

Explanation of Anomaly Identification Methods

The OLVMS®-ML Machine Learning Intelligent Monitoring System simplifies complex and massive data into a scoring mechanism,

allowing users to easily interpret the results.

Outer Layer - Machine Health: The system evaluates the current dynamic conditions based on factors such as

Similarity Score, Vibration Limit Exceedance, Frequency Limit Exceedance, Machine Operation Status, and Overall Score.

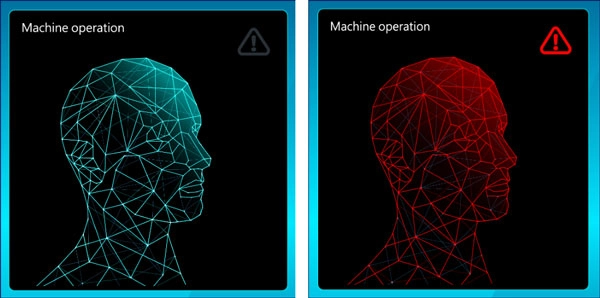

Inner Layer - Dynamic Operation Scoring: A green light indicates normal status, yellow represents a warning, and red signifies an anomaly.

The system automatically compares real-time vibration signals with predefined standards. When a match is detected, the corresponding evaluation result is displayed.

Overall Scoring Mechanism (Outer Layer - Machine Health)

Collision Signal (High Vibration Value Detected), Warning Icon Displayed

Machine Status Management (Inner Layer - Dynamic Operation Scoring)

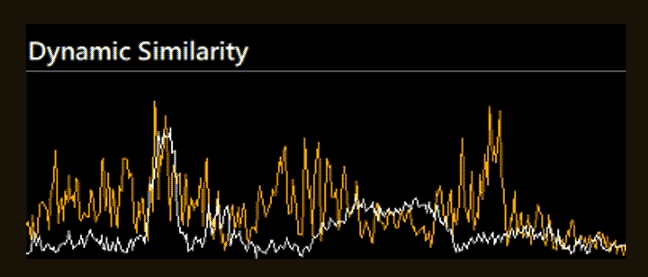

Yellow Line: Defined Dynamic Signal Standard

White Line: Real-time Dynamic Signal

Application Process

Data Refinement Process

The data refinement process converts complex calculations and data into scores and indicator signals.

Architecture Overview

OLVMS®-ML Standalone Single-Channel Version

The OLVMS®-ML Machine Learning Intelligent Monitoring System automatically captures and compares accurate periodic movements. It not only helps assess equipment health but also provides useful insights for manufacturers to make improvements. This allows for early detection of equipment conditions and extends the operational lifespan of machines.

OLVMS®-ML Standalone Single-Channel Version:

● Evaluates whether different equipment operations are suitable for periodic monitoring

● Assesses anomaly detection rates and compares the conditions of good and faulty equipment

● Short-term monitoring of individual equipment to validate continuous online monitoring feasibility

● Manages risks of parallel deployment

● Portable and usable as an inspection tool for equipment status checks

● Collects and verifies stability data after repairs through burn-in testing

Architecture Overview

OLVMS®-ML Standalone Multi-Channel Version

The OLVMS®-ML Standalone Multi-Channel monitoring system is available in configurations of 4, 6, 8, 10, 12, and 16 channels.

OLVMS®-ML Standalone Multi-Channel Version:

● Suitable for factory setups with centralized equipment, supporting up to 16 machines

● Designed for fixed monitoring targets with no future expansion plans

● Ideal for a single core equipment system with multiple critical moving parts requiring real-time monitoring

Architecture Overview

OLVMS®-ML DDS Distributed Architecture

The OLVMS®-ML DDS Distributed Architecture monitoring system consists of three main components: ML CORE Computational System, Edge Data Acquisition Device, and Central Strategy Management System.

● Any edge device and distributed core computational system can operate within the same network domain

● Distributed core computational systems can be added anywhere within the same network

● Edge systems can be deployed anywhere within the same network

● Distributed core computation supports up to 24-channel edge systems

● Software updates are unified across this system

● Edge system configurations available: 1, 8, and 16 channels

AI-Driven Production Line

Eliminate Defective Products

In industrial manufacturing, product quality is the most critical factor.

The OLVMS®-ML Machine Learning Intelligent Monitoring System

enables early detection of production line issues, proactively preventing the creation of defective products.

Usage Benefits

Providing Actionable Insights for Improvement

The OLVMS®-ML Machine Learning Intelligent Monitoring System automatically captures and compares precise periodic movements, generating real-time assessments.

These assessments not only provide insights into equipment health but also offer actionable data for improvement.

By detecting equipment conditions in advance, the system helps extend operational uptime.

This contributes to optimizing production lines, increasing product yield, ensuring equipment stability, reducing maintenance costs, and improving overall work efficiency.

Real-time Anomaly Detection

Quick installation, whether before or after deployment.

Understand Equipment Health

Monitor equipment status and schedule maintenance efficiently.

Predict Mechanical Failures

Identify issues in machinery and take immediate action.

Ensure Product Quality

Establish health standards to guarantee consistency.

Easy Data Collection

Seamlessly gather AI-driven reference data.

Increase Work Efficiency

Significantly reduce workload for engineers and technicians.

Usage Benefits

Providing Actionable Insights for Improvement

Support

Other Machine Learning Applications