Semiconductor Packaging

Solutions|Intelligent Monitoring Solutions for Semiconductor PackagingIn the semiconductor packaging industry, wafer equipment quality has a significant impact on production capacity and product quality. Avoiding unexpected equipment downtime and monitoring equipment health in real-time is essential.

Reasons for Adoption

Industry Trends

The advanced packaging market is projected to surpass traditional packaging by 2027.

According to a Yole Développement industry analysis report, the IC packaging market was valued at $84 billion in 2021,

with the advanced packaging segment accounting for $38 billion (44% of the total market).

The increasing demand for advanced semiconductor chips and complex packaging structures is a major driver of market growth.

By 2027, the advanced packaging market is expected to grow to $65 billion, with a Compound Annual Growth Rate (CAGR) of approximately 10%,

eventually accounting for over 50% of the total market.

*Other application fields include industrial, aerospace, and medical sectors.

*Source: Yole Développement, Technology Development Monitoring Platform

Benefits of Implementation

Precision Maintenance & Repair

With the growing trend of manufacturing automation and optimized workforce allocation, it is essential to shift from traditional sequential maintenance to precision-based maintenance. By optimizing workforce deployment, engineers can improve maintenance efficiency. Instead of trial-and-error component replacements, precision-based repair ensures accurate diagnostics, reducing wait times for critical parts, minimizing misreplacement costs, and improving production recovery scheduling efficiency.

Monitoring Priorities

Key Equipment in Front-end Manufacturing

Unexpected equipment downtime can severely impact production scheduling. Real-time monitoring of equipment health is crucial to maintaining production efficiency. By implementing manufacturing process monitoring, we can establish a quality protection strategy and provide instant abnormality alerts. This helps prevent the mass production of defective products and safeguards customer interests. Additionally, addressing environmental factors, ESG initiatives, and optimizing power and carbon management helps reduce costs and enhance operational control.

Application Cases

M-Series

Monitoring the Stability of Dispensed Adhesive Volume

Controlling the dispensed adhesive volume is crucial for ensuring process stability. Excessive or insufficient adhesive can negatively impact the manufacturing process. A precise dispensing volume ensures uniform distribution, prevents the formation of air bubbles or uneven adhesion, and maintains sufficient bonding strength to keep the wafer from shifting or misaligning during processing.

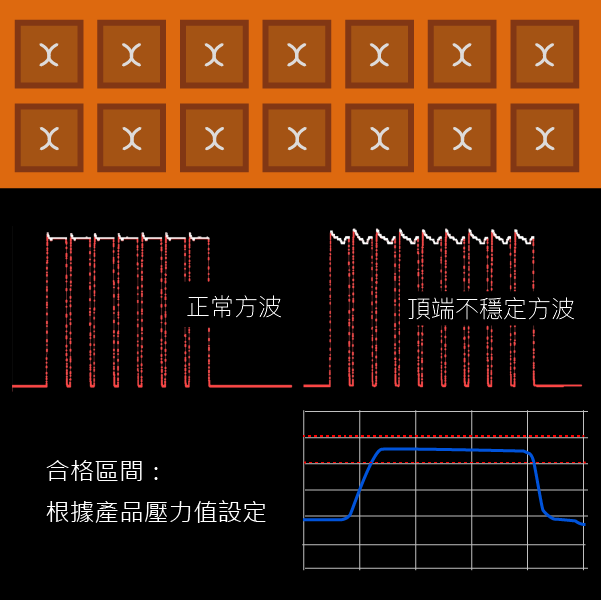

VMS-DDP Ultra-High-Speed Pressure Monitoring System

This system monitors the dynamic pressure signals of each dispensing cycle

to ensure a consistent and uniform adhesive application.

Dispensing pressure settings are customized for each product,

and thresholds are set based on precision standards.

Each dispensing action is logged for future abnormality analysis.

Dynamic dispensing process data is visualized in trend charts,

serving as a secondary criterion for detecting anomalies over time.

2.5D Chip Placement & Reflow Process Monitoring

During the 2.5D packaging reflow process,

chips are pressed and bonded to the substrate.

Pneumatic cylinders are commonly used to control the mechanical pressure applied during bonding,

which is critical for ensuring proper contact and reliable solder joints.

VMS-M14 2.5D Packaging Reflow Furnace Monitoring

This system monitors flip-chip bonding stages during the 2.5D process,

focusing on chip placement equipment.

It ensures high-quality bonding after adhesive application by

monitoring and locking onto specific vibration characteristics generated

when pneumatic or electric cylinders move the heated platen up and down.

By detecting abnormal vibrations caused by aging or malfunction,

this system prevents misalignment and bonding defects.

Application Cases

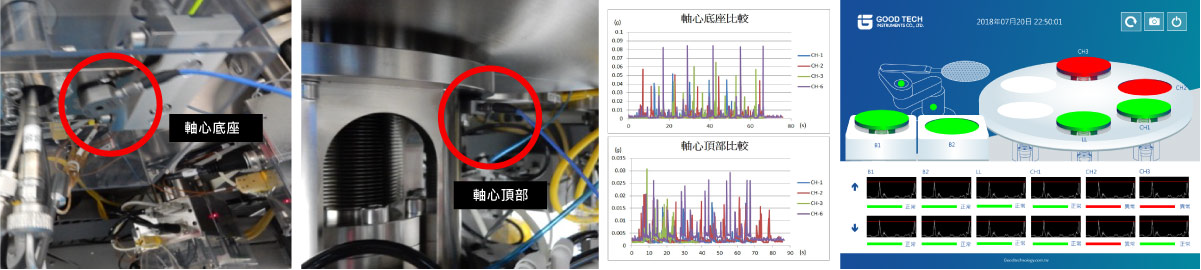

VMS-ML

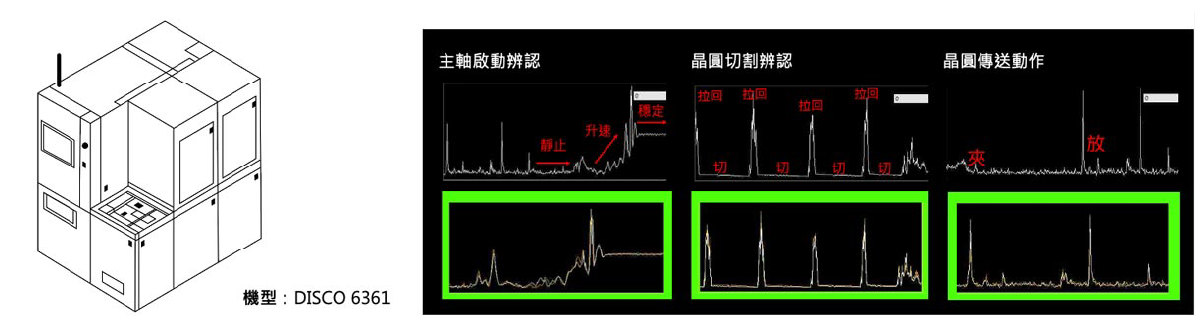

How to Monitor the Mechanical Motion Quality of a Wafer Dicing Machine?

By capturing vibration signals that occur synchronously during spindle acceleration, wafer dicing, and other mechanical operations,

the system learns normal operation patterns and evaluates movement quality.

By comparing with predefined standards, it detects repetitive movements and ensures mechanical motion quality.

VMS-ML Machine Learning Intelligent Monitoring System

This system can monitor the air-bearing spindle quality, blade holder and thread quality, blade and cover fastening status, X Y Z axis movement, servo motor performance, positioning stability, and post-maintenance efficiency.

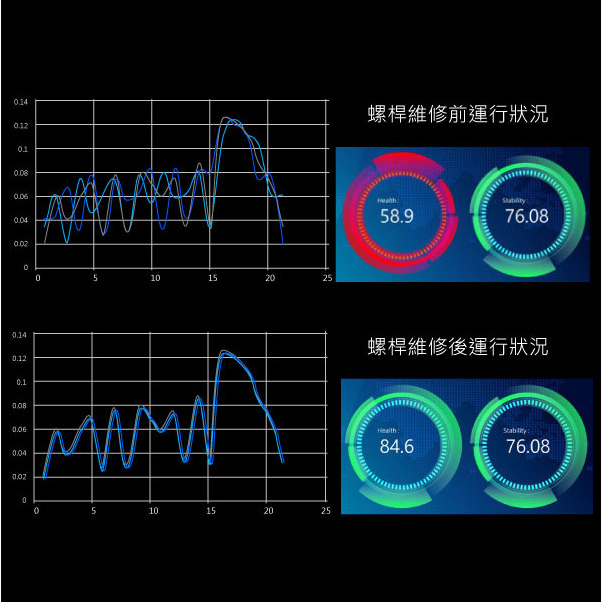

Die Bonder Lead Screw Monitoring?

The lead screw controls the movement of the die bonder, ensuring that the die (semiconductor chip) is precisely placed on the substrate. The precision and stability of the lead screw directly affect the accuracy of die positioning. Some die bonders use the lead screw to adjust pressure, ensuring that the die is properly pressed onto the substrate. Correct bonding pressure ensures proper soldering or adhesion, which impacts the reliability of the packaging process—a critical factor for semiconductor packaging success.

Die Bonder Lead Screw Anomaly?

VMS-ML Machine Learning Intelligent Monitoring System

Using machine learning, the system establishes a dynamic standard for lead screw operation,

enabling comparison of screw performance before and after maintenance.

As shown in the diagram below, before maintenance, timing inconsistencies exist,

leading to a lower dynamic similarity score.

However, after maintenance, timing becomes more consistent, and the similarity score recovers.

Application Case

IIoT

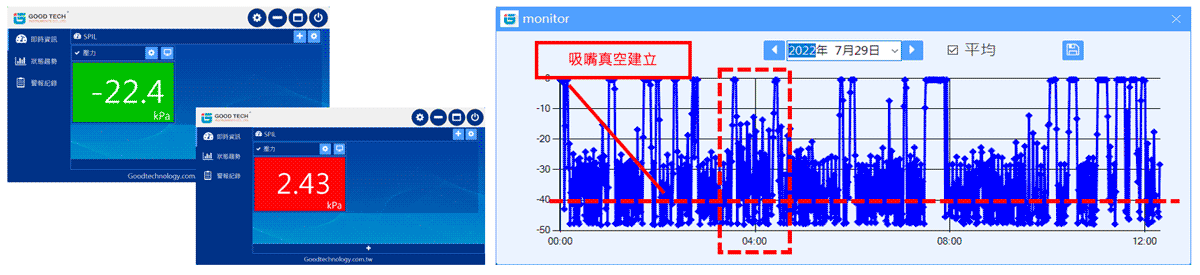

Datacon 8800 Flip Nozzle Pressure Monitoring?

At specific time intervals, the system checks whether the suction action has been triggered properly.

If suction occurs, the system extracts the negative pressure characteristics

and sets a threshold value based on these characteristics.

For example, if the minimum negative pressure is higher than -40, it is considered an anomaly.

Possible causes of pressure anomalies include solenoid valve failure or pipeline damage.

IIoT Pressure Anomaly Alert System

The system allows for the following alarm settings:

・Alarm when negative pressure drops below the threshold

・Alarm when positive pressure exceeds the threshold

Additionally, the system records detailed pressure anomaly events for the Flip Nozzle,

logging the exact time and pressure value of the alarm, and displaying it in real time.

Simultaneous Management of Energy Efficiency and Carbon Reduction?

Companies are increasingly required to achieve carbon neutrality or emission reduction goals

as part of a global effort toward sustainable development.

Effective energy management is a crucial factor in achieving sustainable production,

and reducing energy consumption helps to decrease dependence on natural resources and lower carbon footprints.

Additionally, many large corporations now demand that their supply chain partners participate in

carbon reduction and neutrality initiatives, making carbon emission management within the manufacturing process even more critical.

EMS Energy Management System

This system centralizes power consumption management across dispersed equipment to improve energy efficiency.

It also converts power data into utilization rates and carbon emissions,

allowing for cost-efficient digital management, automatic metering to reduce labor burden,

and precise energy tracking.

Furthermore, it enhances safe production practices and improves equipment efficiency.

Support

Other Semiconductor-related Fields