Semiconductor and Packaging Industry

Case|Semiconductor and Packaging Industry

In the semiconductor and packaging industry, equipment precision and stability are critical.

By monitoring equipment, we can enhance manufacturing accuracy, ensure stable operation, and ultimately improve product quality and production efficiency.

Vacuum Suction Abnormality in Pick-and-Place Operation?

The Pick & Place Machine has become an essential device on production lines. With precision mechanisms and vacuum suction technology, it enables fast and accurate positioning and transfer of components.

Pick-and-Place Operation?Impact of Environmental Micro-Vibrations on Laser Grooving Machines?

The impact of environmental micro-vibrations on high-precision manufacturing equipment cannot be ignored.

Even the smallest vibration can cause laser focus misalignment, affecting the accuracy of grooving.

How can we ensure operational quality?

Bond Head Arm Operating Status?

What is the operational status of the Bond Head arm in the Flip Chip process?

The Bond Head is responsible for connecting chips to connectors, ensuring electrical connectivity and packaging.

How can we verify that the Bond Head arm is operating stably?

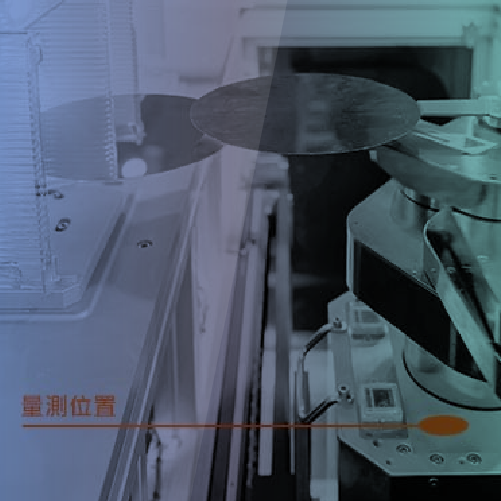

How to Measure Wafer Grinding Spindle?

Does the grinding spindle affect wafer quality?

During the grinding process, the spindle, which has a protective cover, may introduce noise into the measurement data.

How should the measurement be performed effectively?

How to Ensure Stability of Photoresist Coating Machine Arm?

The robotic arm used for wafer transfer in photoresist coating machines must operate with high precision and stability.

To minimize the impact of mechanical vibrations on the wafer surface, how can stability be ensured?

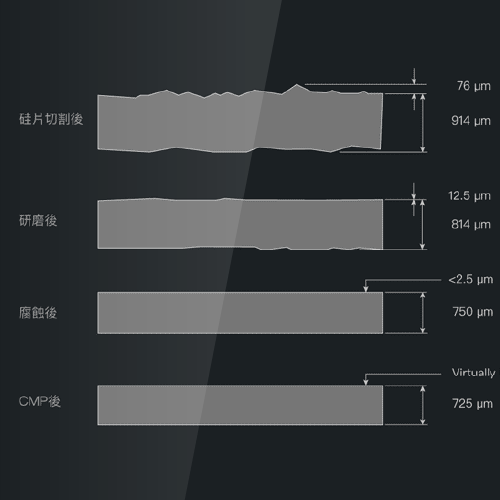

Wafer Grinding Flatness Uneven?

During the grinding process, equipment abnormalities can lead to poor wafer flatness.

How can issues such as rough surface, chamfering defects, and edge polishing irregularities be avoided?

How to Ensure Scrubber Cleaning Process Positioning?

While wafer cleaning is a simple process, the cleaning actions of the scrubber directly impact wafer quality.

How can its stability be ensured?

During wafer cleaning, scrubber machines use a solution to remove particles from the wafer surface.

How to Ensure the Stability of the Die Bonder Process?

Die bonder adhesive machine arm malfunction?

In semiconductor packaging, die bonding is a crucial process.

As technology advances and becomes more complex, how can we ensure process stability and yield rate?

How to Perform Measurements on Mask Aligner?

In semiconductor manufacturing, circuits are created on wafers using light waves.

If vibration occurs during the process, defective products may result.

How can we conduct measurements to detect and prevent anomalies?

The Mask Aligner is a critical device used in the manufacturing of MEMS, optoelectronics, diodes, and large-scale integrated circuits.

How to Prevent PCB Cutting Defects from Damaging Products?

A PCB (Printed Circuit Board) cutting machine is a device used in the electronics manufacturing process to cut PCB boards.

The PCB is a crucial component of modern electronic products, containing electronic components and wiring that support and connect the device’s functions.

Does Exhaust Fan Motor Abnormalities Affect the Manufacturing Process?

If the exhaust fan motor suddenly fails, the fan may not function properly, significantly impacting the production process or the environment.

In some manufacturing processes, specific gases or chemicals must be quickly expelled from the equipment to maintain stable process conditions.

Does Environmental Micro-Vibration in Laboratories Affect Equipment Accuracy?

Using the VC-Curve standard, precision instruments can be strategically placed to prevent performance degradation or accuracy loss due to environmental micro-vibrations, reducing unnecessary costs.

Environmental Micro-Vibration in LaboratoriesCan Excessive Particle Concentration Affect Wafer Quality?

In semiconductor manufacturing, particles refer to extremely small solid or liquid particles, typically measured in microns or nanometers.

These particles can cause instability in the manufacturing process, potentially leading to defects.

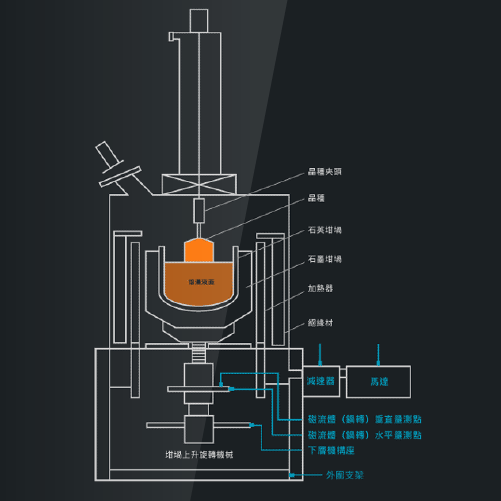

Abnormal Oscillation of the Melt Surface in Crystal Growth Furnace?

Wafers in FAB processes are the most crucial materials in semiconductor manufacturing.

How to diagnose crystal growth furnaces? Preventing abnormal oscillations in the furnace can help avoid defects in seed crystal formation.

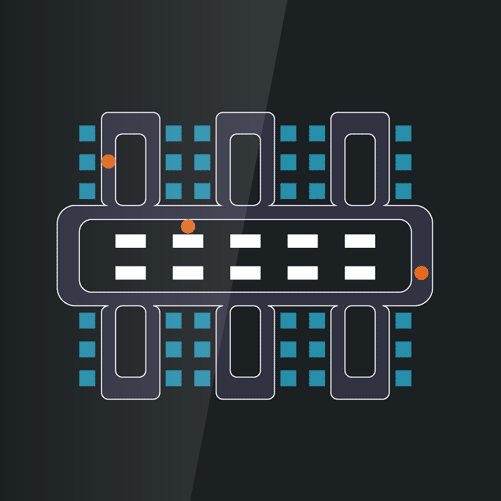

Abnormal Vibrations in OHT Overhead Transport System?

Wafers in FAB processes are the most crucial materials in semiconductor manufacturing.

How to diagnose OHT overhead transport systems? Preventing abnormal vibrations ensures stable wafer handling.

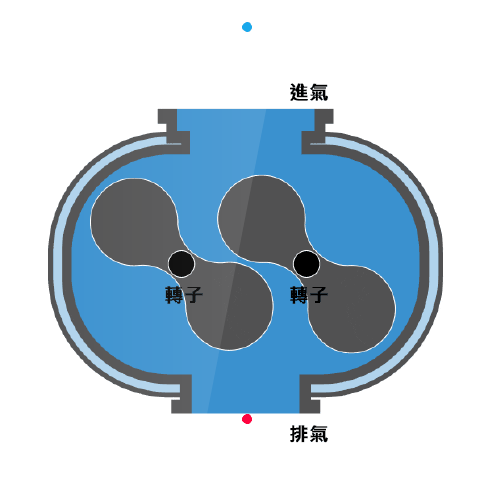

How to Quickly Identify the Cause of Vacuum Dry Pump Failure?

In semiconductor manufacturing, many devices rely on vacuum pumps.

Among them, the Dry Pump plays a critical role in the production process.

How can we prevent unexpected shutdowns of this essential equipment?

Uneven Coating and Film Deposition in the Coating Process?

In semiconductor manufacturing, coating and film deposition processes require extreme precision.

If any abnormal vibration occurs, it can cause uneven coating and defects in the final product.

How can we use measurement tools to ensure process stability?

How to Ensure the Stability of PVD and CVD Machine Arms?

The purpose of thin-film deposition is to enhance the conductivity of wafers.

How can we prevent abnormalities in PVD and CVD machine arms from affecting the process?

How can we ensure stable operation?

Vibration Anomalies in Packaging Stations Leading to Product Failures?

Vibration anomalies at packaging stations can lead to product failures.

The wafer packaging process is highly complex and precise.

If unexpected vibrations occur at a station, how can we immediately stop operations to avoid production losses?

Pneumatic Cylinder Abnormality Leading to Insufficient Thrust?

When a pneumatic cylinder malfunctions, it may cause air pressure backflow, making it impossible to regulate pressure properly and leading to insufficient thrust. How can abnormalities be detected early to prevent production disruptions?

Pneumatic Cylinder AbnormalityHow to Monitor and Measure Equipment Status in PVD Processing?

A well-controlled processing environment is essential for improving production yield. How can the equipment status in PVD processing be effectively monitored and measured?

PVD Processing Equipment StatusHow to Prevent Wafer Scratches During Transport?

When transporting wafers using a wafer-handling robotic arm (Wafer Robot),

unexpected vibrations during transit can cause wafer scratches or collisions.

How can we proactively prevent wafer damage and avoid unnecessary waste?

Die Bonder Screw Abnormalities Causing Poor Product Quality?

Can Die Bonder screw abnormalities lead to product quality issues?

If the lead screw in the Die Bonder is defective, it may cause misalignment of the chip

or improper bonding to the substrate, resulting in positioning errors or weak attachment.

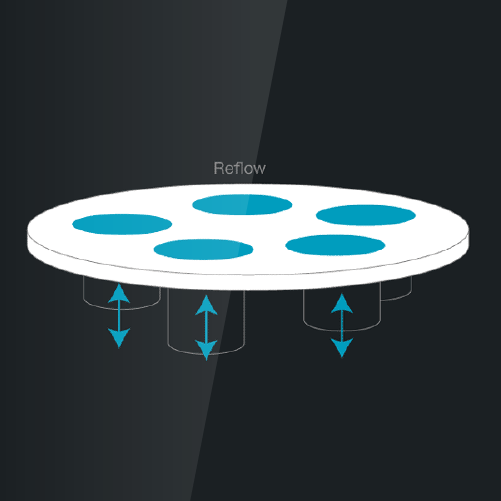

Does the Vibration Quality of the Reflow Oven Blower Motor Affect Temperature?

Reflow soldering involves gradually melting solder and slowly heating the bonding interface

to prevent damage to electronic components due to rapid heating.

Therefore, the quality of the blower motor has a direct impact on temperature control.

How to Monitor the Mechanical Performance of a Wafer Dicing Machine?

Wafer dicing machines are critical in semiconductor manufacturing,

and their performance has a significant impact on the entire process and the final product quality.

How can we ensure the stability of the dicing machine's mechanical operation?

Wafer Cutting Defects Caused by Skewed Blades?

Uneven, misaligned, or defective cutting surfaces not only affect the quality of the die but also impact

the performance of subsequent components or chips in the manufacturing process.

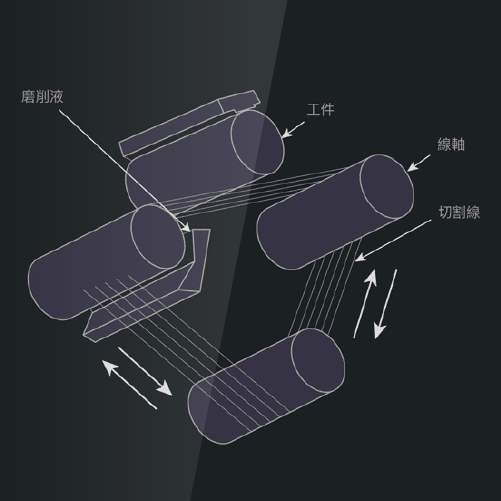

Excessive Vibration Signals in Wire Cutting Machines?

In the cutting process, ensuring minimal warpage, uniform thickness, and minimal blade loss is critical.

How can machine conditions be monitored to maintain cutting efficiency and prevent losses due to equipment conditions?

How to Ensure the Stability of a Dicing Saw?

In the wafer manufacturing process, multiple precision steps can affect the quality and accuracy of chips.

How can the stability of a dicing saw be ensured?

How to Measure the Performance of a Stocker (STK) System?

Stocker systems replace important material transportation tasks.

How can their performance be measured to ensure stable transport? Stockers come in different types and operations depending on the factory requirements.