How to Ensure the Positioning Accuracy of the Scrubber Cleaning Process?

Case|How to Ensure the Positioning Accuracy of the Scrubber Cleaning Process?In wafer cleaning, Scrubber machines commonly use solutions to remove particles from the wafer surface. Although the cleaning process appears simple, the effectiveness of the Scrubber directly impacts wafer quality. How can operational stability be ensured?

Wafer Cleaning

In wafer cleaning, Scrubber machines typically use solutions to remove particles from the wafer surface,

effectively eliminating various surface contaminants while preventing surface defects or scratches.

The spray nozzle's spraying angle and flow rate directly influence the impact force and pressure positioning,

which are crucial factors affecting wafer quality.

Principle of Spray Nozzle

The spray nozzle is an atomizing device that utilizes internal nitrogen pressure to drive liquid at high speeds,

creating atomized droplets through impact. These atomized droplets are sprayed onto the wafer surface,

effectively removing microscopic particles. By ensuring that the spray nozzle reaches the designated position,

it is also possible to track the movement trends of related components for better process management.

Monitoring Explanation

VMS-ML Machine Learning Intelligent Monitoring System

The system converts dynamic sensor signals into visual representations,

allowing hidden process insights to be uncovered and used as a basis for future online monitoring.

In addition, servo motors drive various components, and by utilizing the intelligent monitoring system,

the consistency of each servo motor operation and the accuracy of the Spray Nozzle's positioning can be ensured.

Measurement Conditions

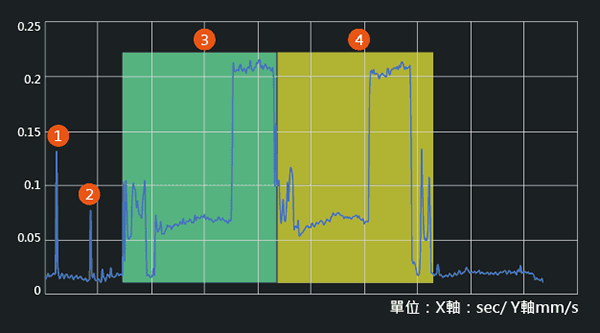

Scrubber Cleaning Process:

1. Z-axis lifting

2. X-axis horizontal movement

3. X-axis horizontal movement + first cleaning

4. X-axis horizontal movement + second cleaning

Single Wafer Cleaning Process

Simulated VMS-ML Machine Learning Monitoring System Measurement

Comparison of Four Wafer Cleaning Conditions

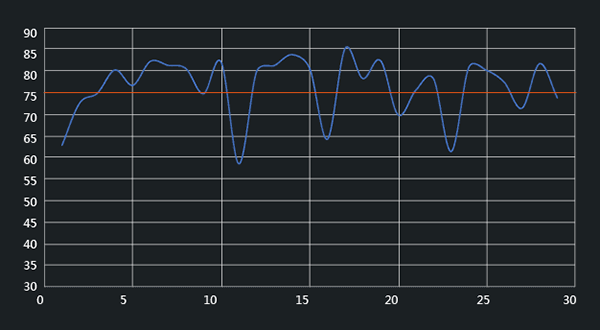

Dynamic Similarity

The system quickly learns and identifies repeated or partially repeated behaviors during the process, with VMS-ML scoring the movement similarity and conducting trend analysis management.

Measurement Conclusion

Benefits of VMS-ML Machine Learning

Equipment Integration: No need to integrate with equipment systems, start monitoring after sensor installation.

Time/Frequency Domain: Simultaneous management of time and frequency domain relationships with VMS-ML.

Edge Computing: No need for large storage space for raw data.

Visual Management: Graphical visualization of equipment operating status.

Focused Management: Visual analysis to pinpoint abnormal axial issues for maintenance.

Pre/Post Maintenance: Assess whether maintenance is needed and verify machine quality after servicing.

AI Trend Analysis: Fine-tuned thresholds and predictive maintenance standards.