How to Monitor the Motion of a Photoresist Coating Machine Robot Arm to Ensure Equipment Stability?

Case | How to Monitor the Motion of a Photoresist Coating Machine Robot Arm to Ensure Equipment Stability?The robotic arm used for wafer handling in photoresist coating machines must maintain high precision and stability to minimize mechanical vibrations that may impact the wafer surface. How can we ensure the stability of the robotic arm?

Photoresist Coating Machine Robot Arm

Specialized Robotic Arm for Wafer Handling in Photoresist Coating Machines

Many factors influence wafer quality during the photoresist coating process, including the precision, stability,

speed, and mechanical vibrations of the robotic arm. The robotic arm must exhibit high precision and stability

to ensure uniform photoresist coating across the entire wafer surface. If the arm experiences instability or precision issues,

it may lead to uneven coating layers, affecting subsequent processing steps.

Vibrations from the robotic arm may transfer to the wafer, impacting the uniformity of the photoresist layer.

Therefore, minimizing mechanical vibrations affecting the wafer surface is crucial.

Monitoring Explanation

VMS-ML Machine Learning Intelligent Monitoring System

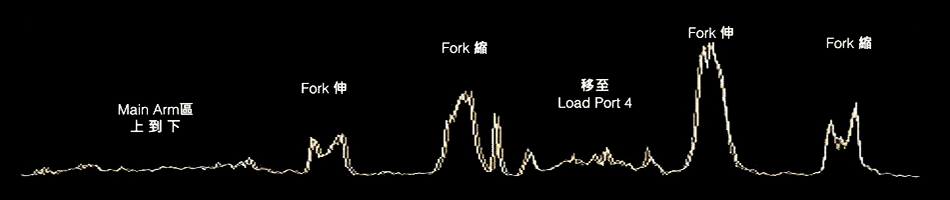

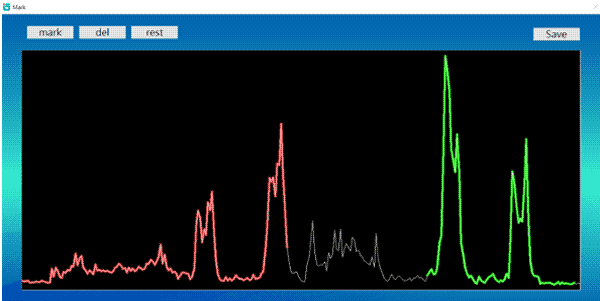

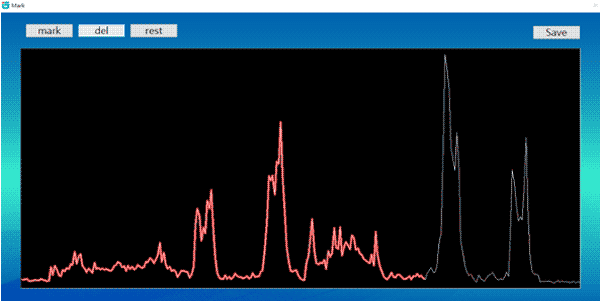

Using the VMS-ML machine learning intelligent monitoring system, we analyze the robotic arm’s movement in wafer

pickup, placement, and transfer processes across the X-axis, Y-axis, Z-axis, and θ-axis. The system learns

the dynamic vibration signals under optimal conditions, enabling pattern recognition and real-time comparison.

The monitoring system detects whether the Z-axis, Y-axis, θ-axis, and X-axis operate in a stable state.

If instability is detected, corrective measures are taken in advance, achieving robotic motion quality detection

and preventive maintenance.

Measurement Status

Action: Robot transfer from main arm to cassette

Detection Objectives: 1. Monitoring the quality of Z-axis movement. 2. Monitoring the quality of X-axis (wafer pickup and placement) movement.

Marker 1: Z-axis only detection

Marker 2: X-axis only detection (Slot 1 placement)

Detection Objectives: 1. Monitoring the quality of Y-axis movement (including θ-axis). 2. Monitoring the quality of X-axis (wafer pickup and placement) movement.

Marker 1: Y-axis and θ-axis only detection

Marker 2: X-axis only detection

Measurement Conclusion

Using the VMS-ML machine learning intelligent monitoring system, the correct motion behaviors are learned and used as benchmarks for monitoring and diagnosis. The system detects anomalies or instability in the robotic arm’s movements in real-time, enabling predictive maintenance and preventing unexpected failures.

Benefits of using VMS-ML for robotic arm health monitoring: Preventing wafer damage due to abnormal arm movements, monitoring the wafer transfer process, and detecting issues such as wafer scratching and misalignment.

VMS-ML Machine Learning Intelligent Monitoring System