Smart Monitoring for Stamping Processes

Solutions|Smart Monitoring for Stamping ProcessesIn the stamping process, the relationship between the press machine and the mold has a profound impact on product quality. Even a slight abnormality in the early stages, such as poor mold quality, displacement, or tool breakage, can lead to defects throughout the subsequent manufacturing process.

Reasons for Implementation

Ensuring Mold Quality

Immediate Detection and Prevention of Defective Products

In a sequence of continuous stamping operations, any minor anomaly in the early stages, such as mold defects, displacement, or tool breakage, can result in defects throughout the manufacturing process, with a rapidly deteriorating trend. The most critical factor in stamping production is the relationship between the press machine and the mold. Due to the high-speed nature of automated stamping processes, any issues arising during manufacturing—such as mold failures, press machine malfunctions, or production line design flaws—can lead to significant material losses and increased production costs.

Core Concept

Providing More Effective and Faster Solutions!

・Automation of Equipment ・ Unmanned Operations (Human-Machine Ratio) ・ Smart Equipment

Big Data

Machine-Learning

AI

Scientific Data

Avoiding Human Error

Optimizing Analysis Processes

Edge Computing

Data Analysis

AI Training

Process Optimization

Trend Prediction

Optimized Decision-Making

Integrated Architecture

Scalability

High Adaptability

Proactively Eliminating Defective Products and Smart Manufacturing

Execution Challenges

Difficulties in Data Integration Between Monitoring Systems and Equipment?

Stamping equipment consists of multiple components with complex structures. When implementing monitoring, challenges arise not only in sensor deployment but also due to the presence of multiple machine manufacturers. Additionally, data is often managed by third-party equipment vendors, making data integration between machines difficult. How can this challenge be overcome?

How to Execute

Non-Intrusive Measurement Without Machine Data Integration

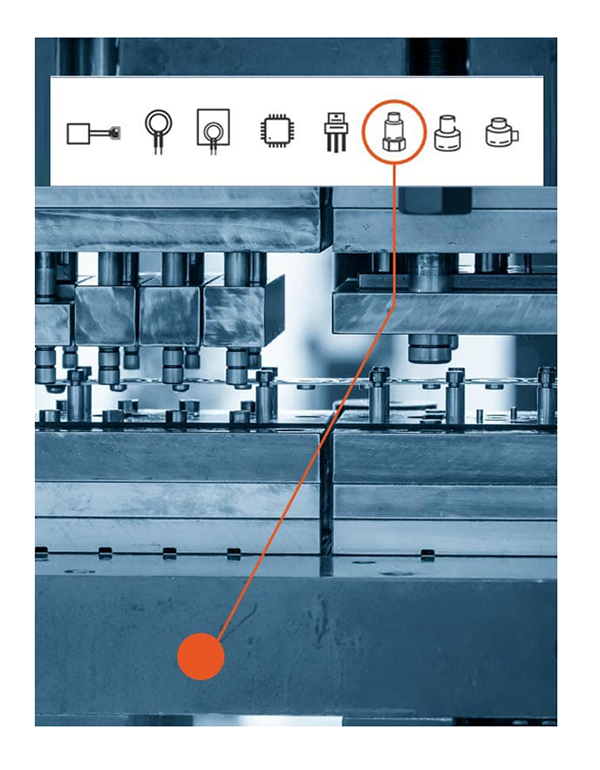

OLVMS®-ML Machine Learning Intelligent Monitoring System eliminates the need for machine data integration,

using a non-intrusive measurement approach to achieve true PLUG & IN.

By installing a single physical sensor based on key process monitoring indicators,

the system can immediately begin monitoring production line quality.

Execution Challenges

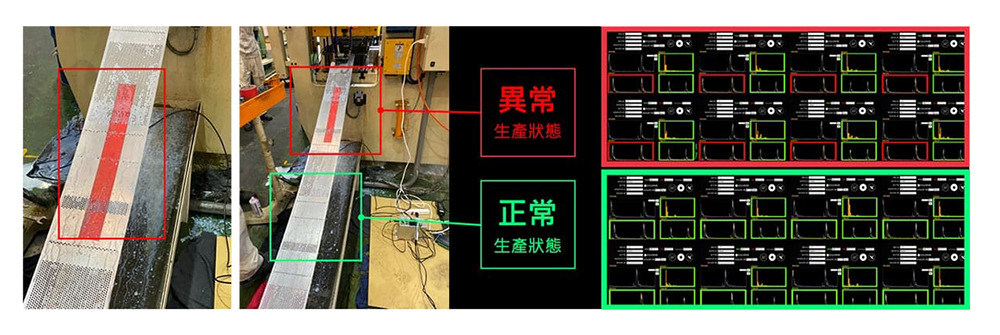

Inconsistent Inspection Standards – How to Standardize and Digitalize Inspection Data?

In stamping processes, product inspection is often subjective, relying on human experience and judgment, leading to inconsistencies. Additionally, minor defects may not be detected in real time, reducing inspection effectiveness. How can inspection standards be unified to prevent quality inconsistencies?

How to Execute

Prevent Human Intervention and Standardize Data Management

Utilizing the VMS®-ML Machine Learning Intelligent Monitoring System, real-time monitoring is conducted. By learning correct process patterns, scientific data is analyzed through algorithms, displaying key results in a simple traffic light system (red, yellow, green) and numerical scores. This eliminates inconsistencies caused by human intervention. Through data-driven management, each workpiece is aligned with quality standards, ensuring consistent product quality.

Execution Challenges

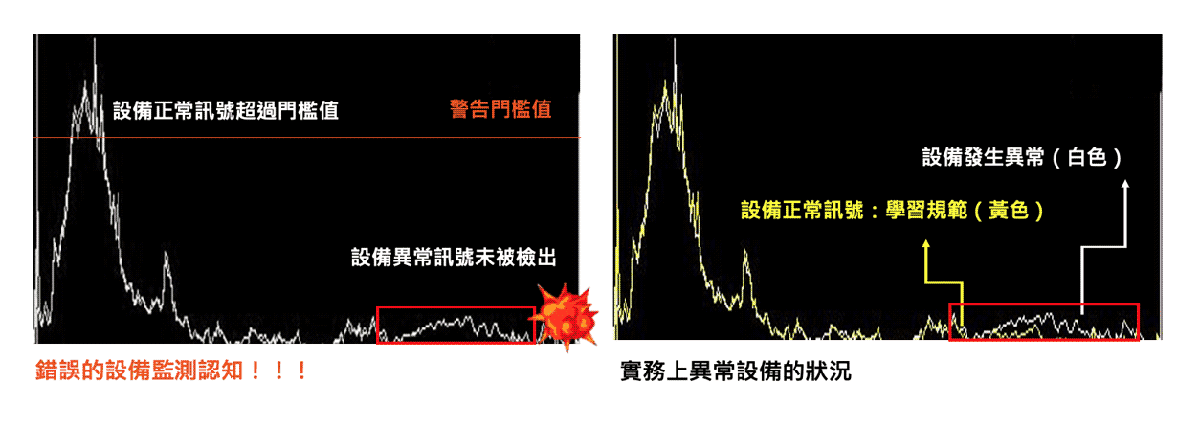

Monitoring with Vibration Thresholds Alone Leads to Misjudgments?

In stamping processes, various transient signals often occur, and normal operation signals frequently mix with abnormal signals. Thus, setting a single vibration threshold as a warning mechanism is insufficient. Additionally, even with the same machine and mold, different materials and rotation speeds will result in varying signal patterns.

How to Execute

Automatically Track and Identify Actions from Simple to Complex

The VMS®-ML Machine Learning Intelligent Monitoring System automatically tracks machining signals and applies different learning models for different manufacturing modes, enabling customized threshold monitoring. Additionally, it automatically detects pre-labeled target signals in real-time monitoring. Even if mechanical motion anomalies occur or external interference is present, the tracking recognition technology can still correctly determine whether the signal belongs to the same periodic action and provide scoring and results.

Execution Challenges

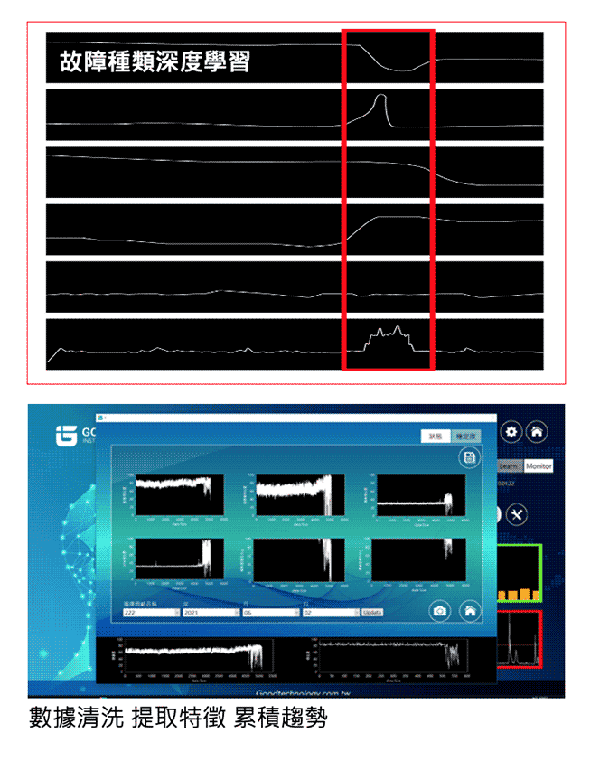

Long Data Collection Time, No Immediate Results?

When implementing a monitoring system, a large amount of data must be collected and accumulated before anomaly detection can extract meaningful features. For different events or manufacturing processes, additional data collection and AI retraining are required. This prolonged data collection process delays the visibility of monitoring benefits, making it difficult to assess system effectiveness in the short term.

How to Execute

Machine Feature Labeling and AI-Based Automatic Identification

VMS®-ML Machine Learning Intelligent Monitoring System rapidly learns and establishes process standards based on correct machine signals,

enabling real-time anomaly detection without the need for extensive data collection periods.

The system also provides AI computing parameters, allowing product developers and test engineers to analyze data for validation and testing.

By categorizing processing behaviors and manufacturing processes, key features are labeled, and a clean process database can be directly incorporated into event-based training.

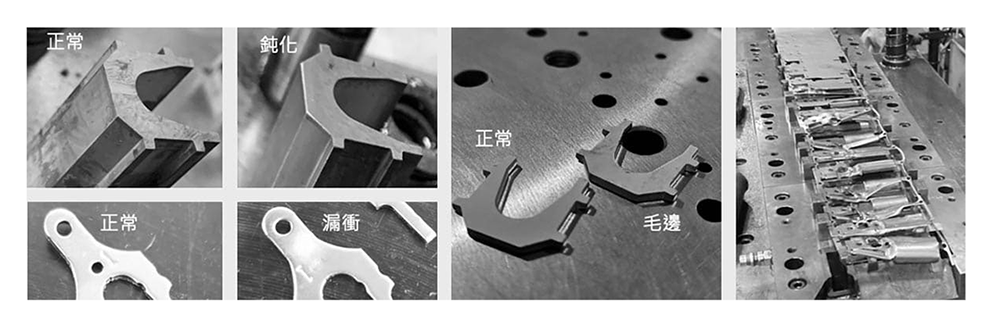

Execution Challenges

How to Proactively Prevent the Production of Large Quantities of Defective Products?

Automated stamping production lines operate at high speeds, meaning that even a minor issue can result in a large number of defective products. For example, tool dulling can lead to burrs on metal components, or displacement can cause finished products to be crushed during processing. How can early detection of production line conditions be achieved to proactively prevent defective products from being produced?

How to Execute

Eliminate Minor Equipment Issues and Predict Future Machine Conditions

VMS®-ML Machine Learning Intelligent Monitoring System can detect even the slightest changes in equipment conditions in real-time. By leveraging system-predicted degradation trends, it provides insights into equipment lifespan. Through predictive maintenance planning, it helps prevent unexpected anomalies and stops the mass production of defective products, allowing for better control over future machine conditions.

VMS®-ML Machine Learning Monitoring System

・Transfers human expertise to quickly learn target motion cycles

・Automatically tracks processing signals and determines results in real time

・Waits for abnormal events and accumulates machine characteristic recognition data

Execution Process

Smart Monitoring Solution for Stamping Processes

Implementation Benefits

Optimized Decision-Making, Problem Resolution

Reducing Idle Time and Increasing Production Efficiency

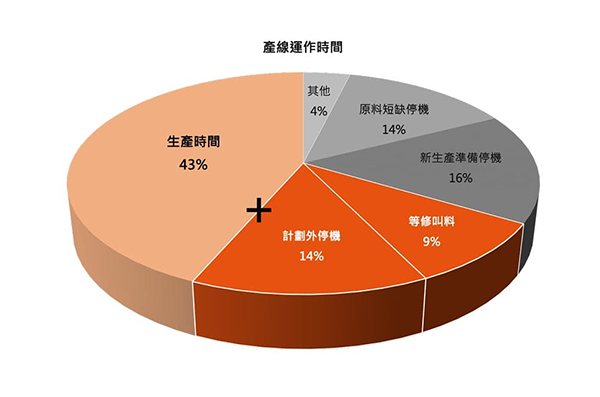

By implementing predictive maintenance planning, production lines can be effectively managed, avoiding unplanned maintenance

and waiting times for parts. This increases usable production time by up to 23%.

Benefit: Efficiently Scheduling Production Lines

Early Detection of Anomalies to Prevent Major Failures

By predicting equipment failures in advance and detecting early warning indicators, maintenance and part procurement can be planned in time.

This reduces the risk of unexpected shutdowns and severe damage by up to 95%.

Benefit: Minimizing Wear and Tear