Does Abnormal Vibration in High-Speed Perforation Machines Cause Defective Products?

Case|Does Abnormal Vibration in High-Speed Perforation Machines Cause Defective Products?When a high-speed perforation machine operates at rapid speeds, abnormal shaking and vibration can easily lead to defective products. How can we prevent these issues in advance?

Processing Characteristics of High-Speed Perforation Machines

High-speed perforation machines are characterized by low-variety, high-volume metal stamping processes, primarily processing materials such as steel, aluminum, and stainless steel. They are commonly used to manufacture speaker metal mesh panels. During the expansion process, minimal waste is produced, significantly reducing material costs.

What is a Metal Mesh Panel (Expanded Metal)?

The perforated characteristics of metal mesh panels (expanded metal) not only protect the delicate internal components of speakers but also feature a modern aesthetic, high flexibility, and long service life. These panels are widely used in architectural decoration, vehicle ventilation grilles, construction site facilities, concrete reinforcement, protective barriers, and more. After processing and design, the holes in the panels can take various shapes, sizes, and colors, such as diamond, circular, and hexagonal shapes.

Due to the rapid stamping process of high-speed perforation machines, any abnormal shaking or positional inconsistency can easily lead to defective products. How can we ensure consistency in each operation?

Solution and Monitoring Explanation

VMS-ML Machine Learning Intelligent Monitoring System

Due to the high processing speed of high-speed perforation machines, the quality of the mold significantly affects product quality. Ensuring mold quality in advance can prevent the production of large quantities of defective products. Therefore, by measuring the quality of the mold and applying machine learning to analyze its dynamic processing signals and standardize its management, we can accumulate data over time and define processing conditions for visualized management. With long-term trend analysis, mold conditions can be predicted in advance, allowing for the prevention of defective products.

Measurement Status

Visual Management of Equipment Operation

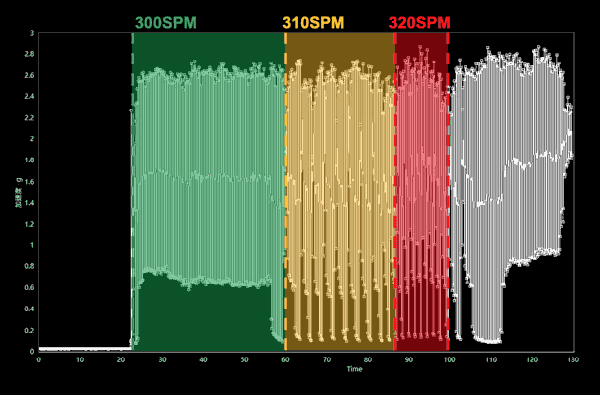

Dynamic signal visualization management converts measured values into intuitive graphical representations, making it easier to identify hidden process issues and providing a basis for future online monitoring.

# Threshold-Based Management: The short-stroke direct drive switch action quantifies the operational behavior.

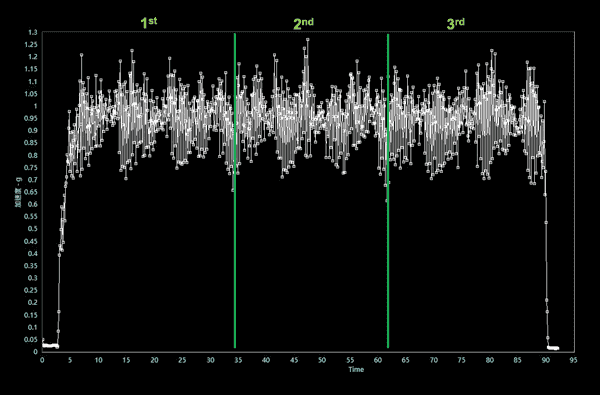

# Machine Learning Management: The machine's operations are managed using machine learning to ensure consistency in each cycle.

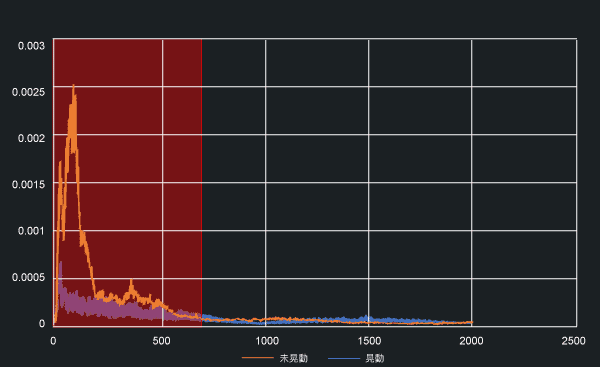

# Identifying Abnormal Signals: In high-speed stamping machines, signals are extremely dense, making traditional upper and lower threshold limits ineffective.

Using the VMS-ML Machine Learning Intelligent Monitoring System, correct specifications can be learned and compared with normal processes to quickly identify abnormal signals.

To quickly diagnose the root cause of anomalies, the VMS-PH Equipment Dynamic Analysis System can be used for dynamic analysis.

Using the intelligent machine learning monitoring system to establish process-specific signal standards.

The image shows the dynamic signal of the expanded mesh machine processing three products.

Using dynamic analysis to define machine processing conditions based on signals from different speeds, achieving visual management and identifying vibration timing differences.

Establishing normal sequence standards using machine learning and comparing them with abnormal timing occurrences.

Machine vibration occurs at low frequencies and can be measured through spectrum analysis.

Measurement Conclusion

Machine vibration can be measured and managed using the VMS-PH Equipment Dynamic Analysis System for dynamic and spectrum analysis. For in-house detection of motors, spindles, screws, rails, XYZ-axis movements, and vibration isolation of the processing platform, the VMS-PM Mechanical Dynamic Analyzer can be used.

Future monitoring of machine processing conditions can be managed using the VMS-ML Machine Learning Intelligent Monitoring System.

VMS-ML Machine Learning Intelligent Monitoring System