How to Ensure Screw Manufacturing Quality and Prevent Mold Damage?

Case | How to Ensure Screw Manufacturing Quality and Prevent Mold Damage?The operational efficiency of continuous molds and equipment in screw manufacturing directly impacts production capacity. How can we ensure the quality of screw manufacturing and prevent mold damage?

Screws and Molds

Small but Mighty Screws

Though small and inconspicuous, screws are found in various objects and machinery in daily life.

From small machines to large industrial equipment, screws play a crucial role. Their quality is vital across industries,

as they impact manufacturing efficiency, product performance, and overall safety.

The efficiency of continuous molds and equipment directly affects the productivity of screw manufacturing plants.

Mold quality also influences screw performance. So, how can we ensure high-quality screw manufacturing, prevent mold damage,

and reduce the probability of reworking defective products?

Threads

Threads are essential for fastening multiple objects together. They are used to create threaded holes that work with screws, bolts, or nuts.

The design and quality of threads impact assembly strength, torque resistance, and sealing performance.

Thread quality plays a critical role in distributing torque and preventing structural failure. Screws often endure different levels of torque forces,

and these forces must be evenly distributed along the thread surface to prevent breakage or deformation due to stress concentration.

High-quality threads enhance durability, structural stability, and overall reliability.

There are various methods for processing screw threads, including turning, milling, rolling, extrusion, tapping, die-cutting, and grinding.

The monitoring in this case focuses on thread rolling in the screw extrusion process.

Screw Extrusion

Screw extrusion, also known as thread rolling or screw forming, is a process for manufacturing threads through plastic deformation.

This method applies pressure to shape threads on a material without cutting, making it ideal for mass production of screws and bolts.

Thread rolling requires materials with good plasticity and is mainly used for small-diameter threads.

The rolling die forms the thread shape through plastic deformation, ensuring a chip-free, high-strength, and high-precision process suitable for large-scale production.

Solution and Monitoring Explanation

VMS-ML Machine Learning Intelligent Monitoring System

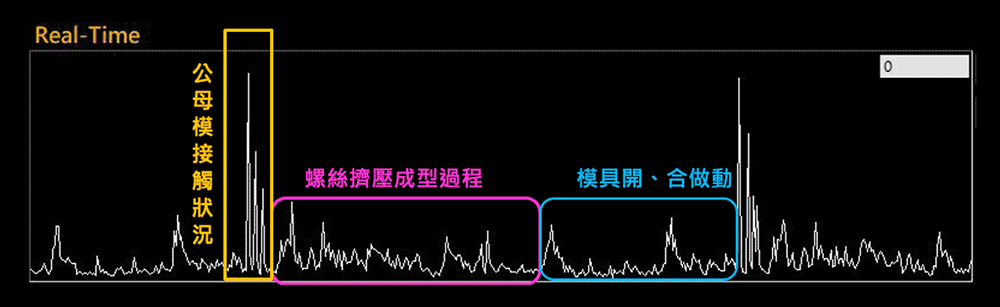

Sensors are installed close to the production mold to capture dynamic signals from proper operational movements.

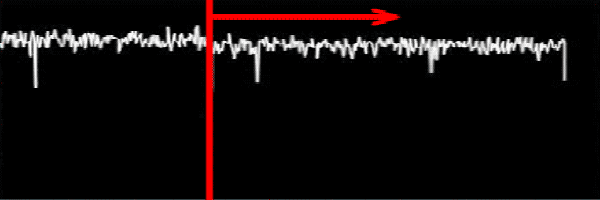

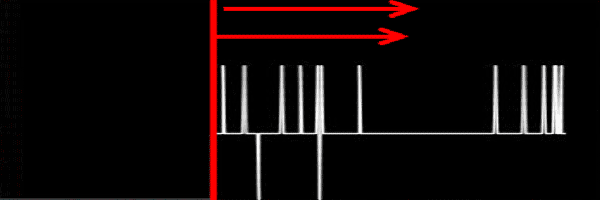

The VMS-ML system learns these signals and compares them to detect abnormalities. By continuously measuring and analyzing trends,

the system identifies the optimal timing for mold replacement, preventing large-scale defective production and minimizing rework.

Measurement Status

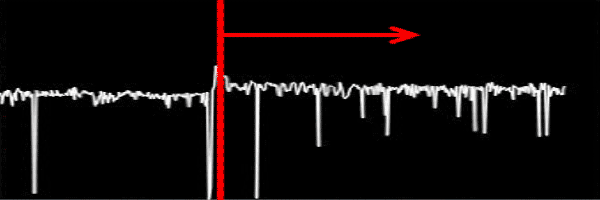

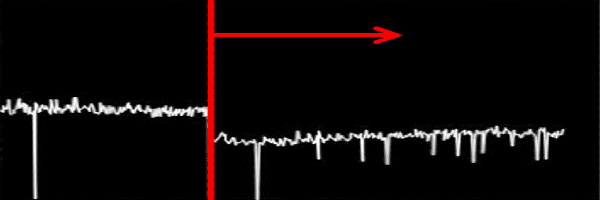

Establishing Learning Standards for Correct Operational Signals

Detecting Anomalies through Changes in Processing Dynamic Signal Similarity

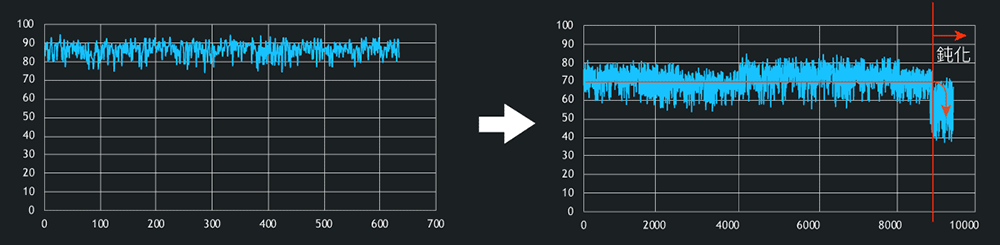

Feature Trend Charts

Similarity Trend Chart – Red Line Indicates Mold Replacement Timing

Frequency Overlimit Trend Chart – Red Line Indicates Mold Replacement Timing

SOA Value Trend Chart – Red Line Indicates Mold Replacement Timing

Frequency Similarity Trend Chart – Red Line Indicates Mold Replacement Timing

Measurement Conclusion

The continuous stamping equipment can efficiently produce up to 43,200 screws per day. With a unit processing cost of approximately 0.3 NTD per screw, the daily production value is estimated at 12,960 NTD. A batch shipment every two weeks (10 days) amounts to around 129,600 NTD. With approximately 10 continuous stamping machines in operation, each mold is valued between 1.2 to 1.5 million NTD, resulting in a daily production value exceeding 1,296,000 NTD.

| Optimization Items | Description | KPI Benefits |

|---|---|---|

| Manual Product Inspection | Can be replaced with Alarm Diversion, Assign One Inspector, 3 > 1 Staff | Annual salary savings for 2 staff: ~1,250,000 NTD |

| Production Line Utilization | Normal tooling has 2.69x better yield than blunted tooling | 5-day batch value: ~400,000 NTD |

| Prevent Mold Damage | Repairs can be performed when the mold is slightly damaged | Per machine damage prevention: ~1,200,000 NTD |

| Prevent Unexpected Downtime | Equipment repair takes around 2-3 days | Utilization capacity value: ~400,000 NTD |

The monitoring system not only helps determine the optimal mold replacement timing through trend analysis, but also prevents equipment damage, ensures high machine utilization, and significantly enhances factory efficiency.

VMS-ML Machine Learning Monitoring System