Customize Inspection Zones, Equipment, and Tasks

Why is it needed?

Why is Inspection & Monitoring Important?

Routine inspections involve scheduled checks of equipment operating conditions, while spot checks focus on specific key assessments at set intervals. The cycle and standards may vary depending on the equipment. Implementing a structured inspection and monitoring system not only ensures standardized management but ultimately aims to enhance equipment stability and reliability by detecting potential abnormalities early and preventing failures.

Key Features of the Equipment Inspection System:

Fixed Monitoring: Clearly defined monitoring points, locations, and inspection parameters.

Fixed Cycles: Different inspection schedules based on equipment type and monitoring points.

Fixed Standards: Specific assessment criteria depending on the inspected equipment section.

Fixed Formats: Standardized documentation and record-keeping for equipment inspections.

By consistently performing routine inspections and monitoring, businesses can:

- Effectively reduce maintenance costs.

- Improve equipment reliability.

- Prevent workplace safety incidents.

- Implement predictive maintenance strategies efficiently.

Common Challenges

Issues Faced in Routine Inspections

Diverse Equipment Types

High Development Costs

Limited Equipment Compatibility

Complex Operation & Usage

As we enter the Industry 4.0 era, factories and production lines are becoming increasingly automated. However, factory environments contain a vast array of equipment with different sizes, specifications, and brands—such as motors, pumps, compressors, air conditioning units, and cooling towers. Large-scale enterprises may have already implemented smart monitoring systems or centralized control rooms, but the **cost of developing these systems is extremely high, and some are even restricted to specific equipment types. For traditional manufacturing plants that operate on limited budgets, many still rely on manual data logging for inspections. With so many essential daily-use devices, is there a more efficient and standardized approach to managing routine equipment inspections?

Feature Description

Compatible with All Smart Devices

No longer constrained by traditional inspection devices,

IMS Industrial Monitoring & Inspection System allows users to freely choose from existing tablets,

laptops, or smartphones. The software system supports both Android and iOS, and users may also opt

for Gude's professional industrial-grade tablets for inspection management.

A unified login system ensures data consistency, preventing duplication or missing records.

Feature Description

Simple Setup for Clear Oversight

Inspection tasks are already complex enough—eliminating tedious manual processes can significantly improve efficiency. IMS Industrial Monitoring & Inspection System removes unnecessary configuration settings, allowing users to start inspections simply by connecting to the internet. This helps reduce workload, improve equipment visibility, and ensure better condition tracking.

Feature Description

Storage on Local Server or Private Cloud

IMS Industrial Monitoring & Inspection System provides the flexibility to store data either on a private cloud server or a local server, ensuring maximum data security for industrial facilities. Users can log in via any existing mobile device, and the system offers customizable deployment based on budget, user needs, and environmental conditions to achieve optimal efficiency.

Feature Description

Flexible Management Structure

IMS Industrial Monitoring & Inspection System is not limited to any specific industry, as it is designed for various inspection and monitoring applications. Since different industries require different inspection methods, the system enables users to customize their management structure, including inspection zones, equipment, and tasks. This allows for the creation of a fully tailored inspection management system.

Benefits

Lower Costs & Easier Management

Reduce Daily Costs

Achieve smart manufacturing by transitioning to digital records, enabling a paperless environment.

This significantly reduces working hours for inspection personnel while accommodating various types of factory equipment.

Enhance Management Efficiency

The IMS Industrial Monitoring & Inspection System prevents human errors caused by unclear records,

allowing faster organization of diverse equipment data.

Minimize Risks & Anomalies

The system provides real-time alert indicators, ensuring thorough inspection & monitoring.

Users can analyze trend data for specific periods and easily retrieve historical records for review.

Strengthen Predictive Maintenance

Assists inspection personnel with wide-area patrol inspections and targeted spot checks.

Standardized processes ensure effective predictive maintenance, keeping equipment in optimal condition.

High Flexibility

No Usage Barriers

IMS Industrial Monitoring & Inspection System offers greater flexibility compared to other inspection systems that require high-cost budgets or impose hidden maintenance fees on users.

UI Features

Customizable Inspection Thresholds

IMS Industrial Monitoring & Inspection System allows users to customize and add specific management details,

define inspection thresholds, and set inspection cycles. This helps maintenance teams prioritize inspection tasks efficiently.

Users no longer need to worry about traditional inspection systems that limit them to specific types of equipment.

UI Features

Status Indicators for Equipment Monitoring

Managing a large number of inspection points can be challenging. IMS Industrial Monitoring & Inspection System simplifies this process with a color-coded indicator system. - Red Light Indicates equipment malfunction or missed inspection. - Green Light: Equipment operating normally. The system also displays a countdown for urgent inspections, allowing users to stay on top of maintenance schedules and track equipment health status effectively.

UI Features

Trend Analysis & Data Visualization

IMS Industrial Monitoring & Inspection System provides trend analysis for selected data periods, allowing users to easily access relevant records. - No need to search through excessive reports or manually compile historical data. - Quick access to past records, eliminating the need to dig through dusty paper archives. - Enhanced clarity on equipment conditions through detailed visual reports.

UI Features

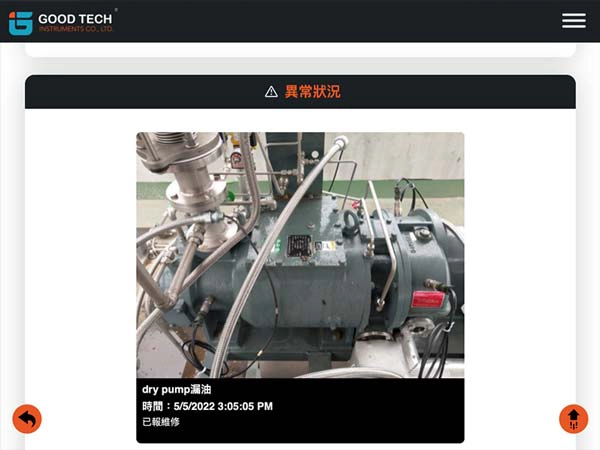

Real-time Photo Upload for Anomaly Reports

IMS Industrial Monitoring & Inspection System leverages smart device cameras for real-time anomaly reporting. - Inspection personnel can instantly capture and upload images when an issue is detected. - Add annotations to document the exact problem. - Reports can be uploaded via mobile devices or desktop computers for better team communication. - Ensures clear, accurate reporting to prevent oversight and speed up repairs.

Applications

Where Can It Be Used?

Machine Inspection

Manufacturing

Equipment Maintenance

Facility Meter Reading

Industrial Safety

Inventory Usage

Energy Management

Environmental Monitoring

Applicable to Any Industry Requiring Inspection

The flexible architecture design allows users to independently set up inspection projects, making it suitable for any industry requiring inspections. Examples include the semiconductor industry, petrochemical plants, wastewater treatment plants, power companies, infrastructure, railway transportation, community property management, pipeline inspection, meter reading personnel, warehouse logistics, fire safety inspections, pharmaceutical and food production, as well as agricultural and aquaculture industries.

Meter Reading Personnel - Equipment Parameter Logging:

Still manually recording inspection data? With IMS, all data is unified and instantly displayed to identify anomalies easily. Applications include production line uptime, good product count, defective product count, visual inspections, operational tests, and various equipment display parameters.

Handheld Inspection Personnel - Routine and Spot Equipment Inspections:

Inspection personnel can utilize mobile devices such as smartphones and tablets. IMS provides the convenience of real-time and on-the-go operations. Applications include temperature, pressure, suspended particles, meter readings, pH values, and various inspection data.

Energy and Power Equipment Management Personnel:

Unsure how to implement ESG initiatives? IMS helps businesses execute power and energy management strategies. Applications include using smart meters or watt meters for measurement and recording data in the system to facilitate power management.

Production Supervisors or Manufacturing Engineers:

For those seeking to optimize production line efficiency and schedule maintenance, IMS assists in planning. Applications include managing various production information and equipment maintenance records.

Safety Supervisors or Environmental Personnel:

Those responsible for industrial safety and environmental control can use IMS to assist in risk assessment and emissions monitoring. Applications include tracking various environmental data and gas emissions records.

Equipment Maintenance Personnel:

Maintenance personnel can use IMS to schedule maintenance tasks, monitor equipment operations, and manage preventive maintenance schedules, reducing downtime. Applications include logging maintenance schedules, identifying failure causes, reporting issues, and tracking maintenance history.

Management or Decision-Making Personnel:

IMS is easy to adopt for managers and decision-makers, providing real-time insights into plant operations, enabling informed management strategies and decision-making. Applications include tracking key data points, production efficiency, energy consumption, and trend analysis.

Problem Solving

Inspection & Predictive Maintenance

The equipment inspection system is not only a basic daily detection method but also a standardized management system. By utilizing the

IMS Industrial Monitoring & Inspection System, users can ease their workload and efficiently manage inspections. According to the

PDCA cycle, the implementation of inspections and point checks follows a structured approach:

Plan (P) → Do (D) → Check (C) → Act (A).

This iterative process enhances production management efficiency and improves equipment quality.

Following the PDCA method, the inspection process begins with broad-range checks to collect data and identify potential equipment issues,

which are then addressed through targeted point inspections. The point inspection system is a structured process of identifying and resolving

problems. Inspections provide a macro-level management approach, while point checks focus on specific problem areas.

Both methods play a crucial role in predictive diagnostics, enabling proactive issue detection and preventive maintenance

to ensure optimal equipment performance.