What is Residual Life Prediction of Equipment?

FAQ|What is Residual Life Prediction of Equipment?In smart manufacturing, many factories are increasingly emphasizing the concept of predictive maintenance. By utilizing various monitoring devices to assess equipment health, factories can implement planned predictive maintenance strategies.

Definition

What is Residual Life Prediction of Equipment?

Residual-life Prediction

Residual-life Prediction is the foundation and core of predictive maintenance management, and in recent years, it has become a hot topic in fault diagnosis, equipment reliability, and system engineering research. In smart manufacturing, many factories are placing increasing importance on predictive maintenance. By utilizing various monitoring devices, they can assess equipment health and implement planned maintenance strategies accordingly.

For users, predictive maintenance is not just about knowing when a machine will fail and scheduling maintenance in advance; it is also about understanding how long the equipment can continue to operate. Once the monitoring system issues an alert, how should maintenance be scheduled? What should be the order of machine maintenance?

Under normal operating conditions, stable usage patterns, and consistent demand, the lifespan of equipment becomes a critical factor affecting production efficiency. We can collect various sensor data (data measurement), select relevant data for analysis (data selection), remove noise and interference (data preprocessing), extract critical features, and use these features for machine learning comparisons and evaluations.

Concept Explanation

The Concept of Residual Life Prediction for Equipment

The factors that affect the lifespan of equipment are quite similar to those that influence human longevity. A person’s health condition is initially determined by genetics, and over time, aging leads to physical decline. Additionally, environmental pollution and unhealthy lifestyle habits can further impact a person's lifespan.

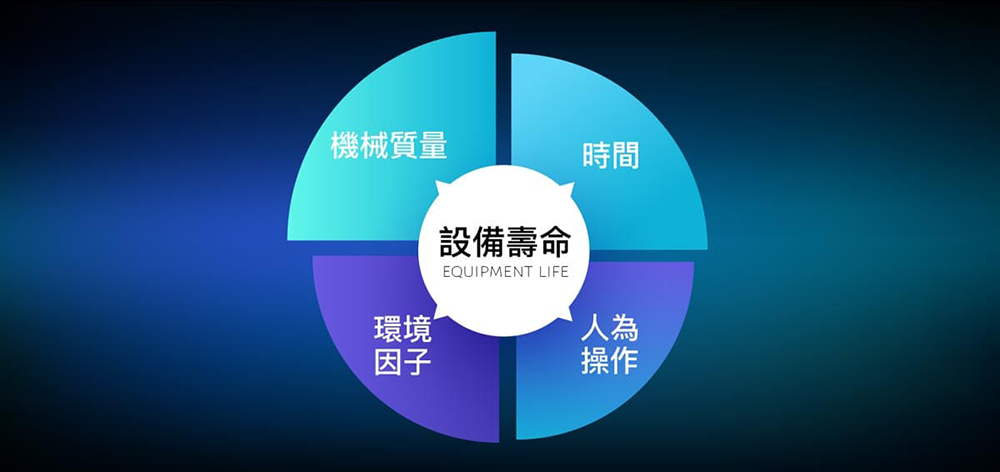

Similarly, the lifespan of equipment is influenced by four main factors: mechanical quality, time, environment, and human factors. While it is impossible to completely prevent the wear and tear caused by long-term usage (time factor), we can still monitor the condition of the equipment, avoid improper environmental usage, and address minor issues early before they worsen. Additionally, proper maintenance can help extend the lifespan of the equipment.

The main purpose of Residual Life Prediction is to provide users with a clear timeline for predictive maintenance based on known forecast data. This allows for proactive planning of repairs and maintenance, reducing production downtime, extending equipment lifespan, and maintaining a consistent quality level of equipment performance.

Predicting Equipment Residual Life

Different Prediction Methods for Various Types of Equipment

Tailored Solutions: Different Prediction Methods for Various Equipment Types

For rotating machinery Goodtech’s VMS-RM Online Rotor Health Monitoring System is equipped with an AI-powered intelligent algorithm that cross-analyzes data. This system not only provides insights into equipment conditions and potential rotor anomalies but also predicts the equipment’s condition trends for the next seven days.

For cyclical production equipment, which operates under complex mechanisms and workflows, the OLVMS-ML Machine Learning Intelligent Monitoring System can be used for real-time monitoring and feature learning. By continuously accumulating and comparing data and characteristic patterns, the system predicts the remaining useful life of the equipment, allowing users to prepare for maintenance in advance.