Monitor Spindle Condition to Prevent Production Line Quality Issues

Why is it needed?

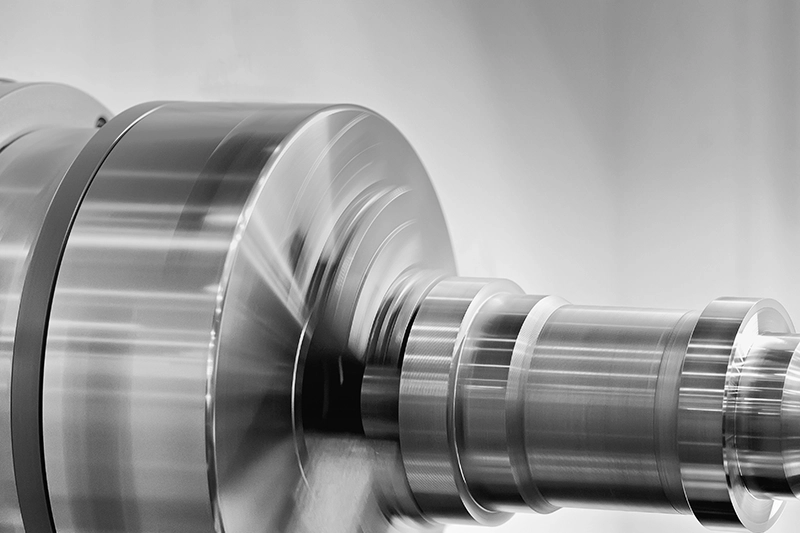

Why is spindle quality important?

The motion precision and structural rigidity of a spindle determine machining quality and cutting efficiency, significantly impacting product quality. External environmental factors or improper usage can lead to machining precision errors or spindle wear, further shortening the lifespan of the machine or increasing product defect rates. Therefore, the spindle is often referred to as the "heart of the machine tool" and is a critical component of equipment, requiring stringent quality standards.

Understanding spindle quality and conducting timely maintenance ensures stability, extends spindle lifespan, and prevents unexpected repairs or failures during operation. But with numerous machine tool spindles and equipment spindles in the factory, how can an efficient inspection and management system be established?

Common Issues

Common Spindle Failures?

Machine tool spindles typically use servo variable-speed motors, which have a relatively simple structure. However, common spindle failures often occur in these key components. When a critical spindle experiences abnormalities, the root cause is usually multifaceted. Typical signs of spindle failure include rapid overheating, decreased rotational accuracy, increased operational noise, and frequent component failures leading to shortened lifespan.

Spindle Overheating Rapidly

Decreased Rotational Accuracy

Increased Operational Noise

Frequent Component Failures

How to Solve

What Data Should Be Collected for Spindle Management?

ISO Standards

Spectral Characteristics

Acceleration, Velocity, Displacement

Resonant Speed

Many critical pieces of equipment cannot afford to fail. Over the past decade, detection technology has matured, and various diagnostic techniques have been applied in factories, integrating with preventive maintenance programs. By measuring key characteristics of the equipment, users can monitor the condition of their machines and schedule maintenance or repairs in advance.

For spindle health monitoring, GoodTech has introduced the portable IMS-SC Spindle Health Inspection Analyzer, allowing users to efficiently manage spindle conditions. The system is specifically designed for spindle diagnostics, incorporating comprehensive international ISO recommended standards, making it easy to assess spindle status and providing users with essential data to schedule timely maintenance and repair.

Feature Description

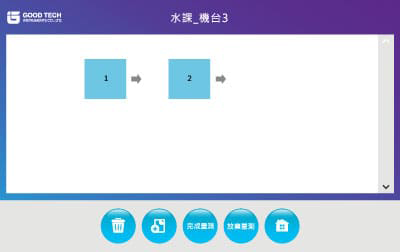

Creating a Dedicated Inspection Map for Machine Tool Spindles

IMS-SC Spindle Health Inspection Analyzer is designed to provide the necessary measurement functions for machine tool spindles. It allows users to create customized inspection maps based on different workshop attributes and set up various measurement points for each piece of equipment.

The system displays real-time equipment status on the map, using indicator lights to assess quality conditions. This provides users with a clear basis for immediate maintenance and scheduling of preventive care.

Feature Description

Predictive Maintenance for Various Spindle Types

IMS-SC Spindle Health Inspection Analyzer evaluates spindle health by measuring vibration signals at non-rotating parts of the spindle. It is suitable for quality assessments of direct-drive, gear-driven, belt-driven, and built-in spindles, helping to prevent unnecessary emergency shutdowns.

Engineers and operators can utilize trend charts and numerical data to assess equipment conditions, thereby improving maintenance efficiency and effectiveness.

Feature Description

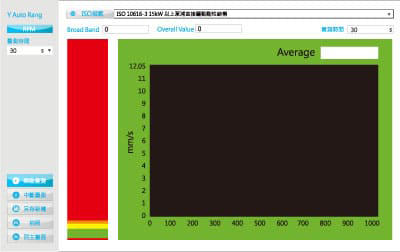

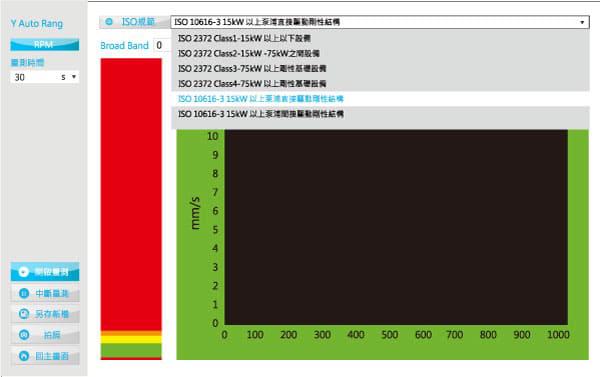

Built-in ISO Vibration Reference Standards

IMS-SC Spindle Health Inspection Analyzer defines equipment status based on ISO vibration standard guidelines, categorizing it into four levels: Excellent, Normal, Warning, and Dangerous. Users can also define custom threshold standards. Measurement results are displayed instantly, providing clear insights without needing to wait for an inspection team to arrive, enabling immediate issue resolution.

Additionally, Goodtech leads the market by integrating the latest ISO 20816 standard, offering users a more comprehensive tool for managing motor and spindle components.

Feature Description

Portable, Intuitive Touch Interface for Easy Operation

The portable IMS-SC Spindle Health Inspection Analyzer allows instant measurements anywhere. With an IP65-certified waterproof and dustproof industrial computer, this portable analyzer can be used for easy inspections without requiring professional expertise.

With just a few simple steps, users can categorize and manage spindles across different workshops in the facility, making equipment management more efficient and streamlined.

The Heart of Machine Tools

Predictive Diagnostics

The spindle, a critical core component of machine tools, benefits greatly from the implementation of predictive diagnostics and proper inspection and maintenance plans. This approach effectively enhances machining precision and product quality, reduces defect rates, and extends spindle lifespan.

Feature Description

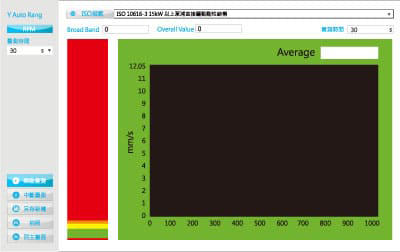

UI Functional Interface

Real-time Monitoring of Spindle Health

IMS-SC Spindle Inspection Analyzer displays spindle health status using indicator lights:

Red: Abnormal / Green: Normal.

Users can immediately respond and make maintenance decisions accordingly.

Spindle Vibration Quality Inspection Standards

ISO-10816

Measurement Types: Small, Medium, and Large Rotor Machinery

Speed Range: 120-15000 RPM

Test Conditions: No-load testing

Classification Criteria: Power, Shaft Height, Structure (Flexible or Rigid)

ISO-17243

Bearing Type Restriction: Rolling Bearings

Speed Range: 600-30000 RPM

Spindle Type: Built-in Spindle

Test Conditions: No-load testing (No cutting, milling, or grinding)

Classification Criteria: Power, Maximum Speed, Bearing Type (Ball or Roller Bearings)

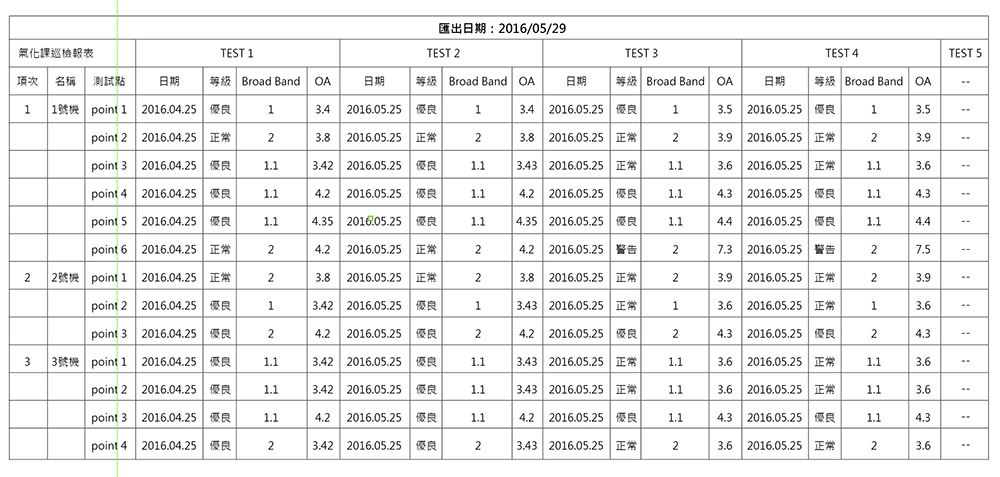

Report Display Example

IMS-SC Spindle Inspection Analyzer automatically categorizes and generates historical measurement reports for quick preview.

Usage Process

Simplified Setup Process

IMS-SC Spindle Inspection Analyzer allows users to create an inspection map independently. With just a few simple steps, users can classify and manage spindles in different workshops within the factory, making spindle management more efficient and convenient.

1. Create a Map

2. Establish Inspection Points

3. Define Measurement Points

4. Measurement Interface

5. Select the Appropriate Standard

6. View Equipment Results

Benefits

Instant Feedback

IMS-SC Spindle Health Inspection Analyzer features a lightweight touchscreen with an intuitive interface. Designed specifically for spindle measurement needs, it allows for plug-and-play functionality, enabling inspectors to conveniently carry and test spindle equipment. The tablet screen instantly displays the device status and test results, providing precise maintenance recommendations and predictive maintenance insights. This helps users optimize maintenance planning, effectively prevent spindle failures caused by wear, and reduce unnecessary maintenance costs.

Quick to Learn

Equipment Control

Precision Maintenance

Enhanced Efficiency

Reduce Wear

Lower Costs

Application

Target Equipment

Application Fields:

Semiconductor industry, petrochemical plants, food factories, pharmaceutical factories, paper mills, panel manufacturers, LED factories, power plants, pumping stations, wastewater treatment plants, manufacturing, equipment manufacturers, maintenance service providers, etc.

Target Equipment:

Direct-drive spindles, belt-driven spindles, gear-driven spindles

Built-in spindles: Internal grinding built-in spindles, engraving machine built-in spindles, machining center built-in spindles.

Lathe spindles: Belt-driven horizontal and vertical lathe spindles, gear-driven types.

Milling machine spindles: General machining spindles, drilling machine spindles, gear-driven spindles.

Grinding machine spindles: Internal grinding spindles, external grinding spindles.

Specifications

Perfect Integration of Hardware, Electrical, and Software

Equipped with a USB interface for easy access to measurement data, full-touch input, and a 10-inch full-color display for real-time measurement data and computation results. The lightweight design allows users to easily carry it for on-site measurements. It also supports an expandable camera function for capturing measurement environments effortlessly. Certified with IP65 international protection rating for water and dust resistance.

Support

Other Topics Related to Rotating Machinery