Monitor Turbine Pump Status and Make Accurate Decisions

Why is it needed?

Common Turbine Pump Issues in Factory Operations

Is the equipment in good condition?

With numerous turbine pump motors, conducting inspections one by one consumes a significant amount of time. Organizing and analyzing data is also a complex task to accurately assess equipment status.

How to plan maintenance?

After data analysis, scheduling maintenance remains dependent on human experience, leading to inconsistent standards across equipment. A more data-driven approach is needed for reliable planning.

How to determine spare parts inventory?

Many components require early procurement. When a failure occurs without a clear cause, the only option is to return it to the manufacturer for replacement. Some parts have long lead times, making inventory planning difficult.

Unplanned downtime causes losses

Even with routine inspections, a lack of real-time equipment monitoring can result in unexpected shutdowns. This not only raises safety risks but also disrupts production lines, leading to increased scrap rates.

Common Issues

Common Failures in Turbomolecular Pumps

The Turbomolecular Pump, abbreviated as Turbopump, utilizes high-speed rotating blades to convert gas molecules into compression energy. Due to the complexity of its structure compared to traditional mechanical pumps, monitoring a turbopump is more challenging. When malfunctions occur, they can pose serious safety hazards and significantly impact production quality. Implementing a proper inspection and maintenance strategy is crucial to avoiding unplanned downtime, ensuring predictive maintenance, and extending the equipment's lifespan.

Overload

Suction Failure

Blade Collision

Oil Backflow

Overheating

Foreign Object Ingress

How to Solve

Effectively Improve Inspection Efficiency

Customize inspection maps based on industry or factory area.

Apply customized standards to interpret pump conditions and display real-time measurements.

Measurement data, spectrum analysis, and algorithms combined for user-defined thresholds.

Users can name and create multiple measurement points for turbine pumps.

Monitor pump conditions, identify abnormalities, and provide precise maintenance guidance.

Inspection maps clearly show equipment status, historical reports, total measurements, and trends.

Easily create turbine pump inspection maps with simple steps—no technical background required.

Portable measurement device with IP65-certified waterproof and dustproof industrial-grade computer.

Feature Description

Create Inspection Maps for Turbomolecular Pump Equipment

IMS-TP Turbomolecular Pump Inspection Analyzer allows users to categorize and create customized maps based on different factory areas and equipment attributes. Users can also set up multiple measurement points for each piece of equipment.

The system provides real-time status updates on the map, with indicator lights to assess equipment condition, helping users efficiently schedule maintenance and inspection tasks.

Feature Description

Applicable Predictive Maintenance for Various Turbomolecular Pumps

IMS-TP Turbomolecular Pump Inspection Analyzer is suitable for quality inspection of various turbomolecular pumps. Users can set different standards based on specific model speeds, allowing greater flexibility in application. Facility personnel can utilize trend charts and numerical data to assess equipment conditions, enhancing maintenance efficiency.

Feature Description

Users Can Set Custom Threshold Values

IMS-TP Turbomolecular Pump Inspection Analyzer integrates user-defined standards with specialized algorithms, providing real-time equipment status updates with clear results. Users can establish custom measurement threshold values or opt to use manufacturer-provided data for setting benchmark standards.

No need to wait for inspection personnel to arrive—issues can be resolved immediately. This system also helps users develop their own in-house equipment health management standards.

Feature Description

Portable and Intuitive Touch Interface for Easy Operation

The portable IMS-TP Turbomolecular Pump Inspection Analyzer enables on-the-spot measurements. By applying customized standards, users can easily perform inspections without requiring a specialized technical background.

Proper Implementation of

Inspection and Maintenance

With a large number of turbomolecular pump units, implementing the correct inspection and maintenance procedures at the right time ensures smooth production line operations. Furthermore, it can even extend the lifespan of the pumps.

Function Description

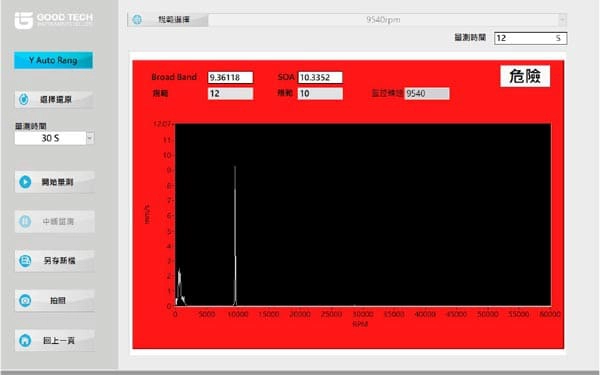

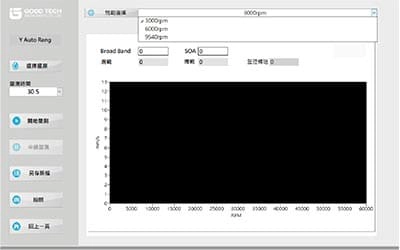

UI Functional Screens

Real-Time Equipment Status Display

IMS-TP Turbomolecular Pump Inspection Analyzer will trigger a red danger alert on the system interface if either the Broad Band value or SOA value exceeds the set threshold.

Custom Measurement Standards

IMS-TP Turbomolecular Pump Inspection Analyzer does not have preset standard values. Users can establish an optimal threshold by measuring well-functioning equipment. Once the standard is set, users can create a measurement map and perform inspections on pumps with the same rotational speed type.

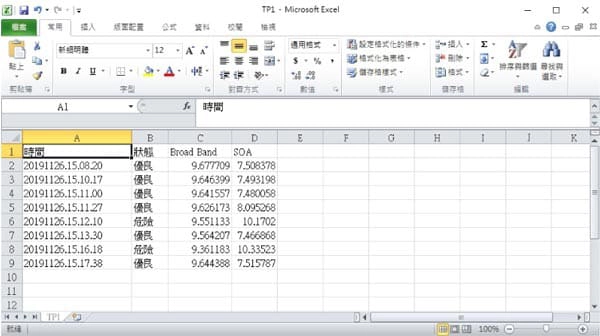

Report Representation

IMS-TP Turbomolecular Pump Inspection Analyzer allows users to manage raw data efficiently and generate trend data reports for each measurement point in CSV format.

Benefits

Instant Feedback

IMS-TP Turbomolecular Pump Inspection Analyzer features a lightweight touchscreen with an intuitive interface, designed for easy operation. The system is tailored for the specific measurement functions of turbomolecular pumps, allowing for plug-and-measure functionality. It enables inspection personnel to conveniently carry out on-the-spot assessments, with real-time display of equipment status on a tablet screen. This tool provides precise maintenance guidelines and predictive maintenance references, helping users optimize maintenance planning, prevent unexpected production line shutdowns, and reduce excessive maintenance costs.

Quick Learning Curve

Equipment Monitoring

Accurate Repairs

Improved Efficiency

Prevent Downtime

Lower Costs

Applications

Target Users

Factory Maintenance Department:

Factory equipment maintenance and inspection personnel, replacing human intuition with data-based verification.

Facility/Equipment Engineers:

Confirm equipment status, providing data-based evidence for repair requests.

Outsourced Equipment Maintenance Contractors:

Facility-wide maintenance contractors responsible for periodic inspections and maintenance services.

Equipment Manufacturers:

Verify equipment issues during scheduled maintenance, providing customers with repair/replacement services and assisting in record-keeping.

Equipment Repair Providers:

Provide data-based maintenance insights or offer routine inspection services for clients.

Applications

Target Equipment

Precision Analytical Instruments (Mass spectrometry, microscopy, etc.)

Semiconductor Industry (Electronic components, integrated circuits, solar cells, etc.)

Optics/Glass Industry (Thermal protection, anti-reflective coatings, reflective coatings, optical filters, etc.)

Vacuum Coating Technology (Surface protection, decorative coatings, display technology, screens, etc.)

Vacuum Metallurgy (Vacuum welding, vacuum sintering, vacuum alloying, vacuum furnaces, etc.)

Gas Leak Detection (Vacuum systems, vehicle fuel tanks, airbags, vacuum packaging industry, etc.)

Scientific Research Facilities (Nuclear particle physics, nuclear fusion research, laser applications, etc.)

LED & Lighting Industry (Lighting production, etc.)

Specifications

Perfect Integration of Hardware, Electronics, and Software

Equipped with a USB interface for easy access to measurement data, featuring a fully touch-operated input system and a 10-inch full-color screen. Measurement data and computation results are displayed in real time. The lightweight design makes it easy for users to carry the device to on-site measurement environments. Additionally, it supports an optional camera for capturing images, allowing seamless documentation of measurement conditions. Certified with IP65 international protection standards for water and dust resistance.

Support

Other Topics Related to Rotating Machinery