Ensure Production Line Stability

Download

Rotor Health Monitoring System - Wired Version

Ensure the Stability of Key Production Line Equipment

Why is it needed?

The Importance of Monitoring Critical Rotors in the Manufacturing Process?

Monitor Key Equipment Status to Ensure Production Line Stability

Key equipment includes high-precision servo motors, precision positioning system motors, high-speed motors, linear motors, and high-reliability drive systems. These rotor-driven motors provide high-precision control and positioning, significantly impacting production line quality.

If critical process equipment experiences unexpected downtime, it can lead to damage of semi-finished products on the production line. Monitoring key equipment status is essential for maintaining production line stability.

Common Challenges

Common Issues in Monitoring Key Rotors in the Manufacturing Process

Inconsistent Equipment Brands and Models

The factory has a large number of rotor devices from various brands, models, and purposes. How can they be managed uniformly?

Production Lines with Zero Downtime Tolerance

Critical rotor equipment in essential production processes cannot be stopped. How can monitoring and management be executed?

Complex Monitoring Software Operation

Monitoring system setup conditions are complicated. How can we make it easier for operators to use and ensure a smooth handover?

Difficult Equipment Status Interpretation

Equipment status is assessed differently based on personal experience. How can data management be effectively implemented to ensure accurate diagnosis?

Effectiveness of Maintenance and Repairs

Is outsourced maintenance effective? When should equipment be repaired? How can maintenance timing be evaluated?

Data Collection and Planning

Haven’t implemented predictive maintenance planning yet? After collecting a large amount of equipment data, are you still unsure how to proceed?

Feature Description

Equipped with a Three-Axis Sensor, Providing Over 20 Types of Data

RM-IoT-Online Rotor Health Monitoring System (Wired Version) utilizes MEMS accelerometers, enabling omnidirectional measurement by simultaneously detecting three axes (X, Y, Z), providing comprehensive 3D data.

Since it can measure multiple directions simultaneously, it simplifies configuration compared to installing multiple single-axis accelerometers. The collected data is highly detailed, offering up to 20+ types of information. Users can leverage this data for AI training, optimizing system processes in the future.

Feature Description

Built-in ISO Standards, Easy to Use Without Technical Background

The system is built with ISO 10816 / 20816 / 2372 standards, defining equipment status into four levels: Excellent, Normal, Warning, and Dangerous. Measurement results are displayed instantly, allowing users to quickly assess conditions without waiting for on-site inspections. This helps users establish their own equipment health management standards.

Additionally, Good Tech takes the lead over all other monitoring software on the market by incorporating the latest ISO 20816 standard, enabling more comprehensive management of motor rotor components.

Feature Description

Wired Architecture for Stable and Uninterrupted Data Transmission

Critical production line equipment significantly impacts product quality, requiring real-time monitoring and rapid status updates. The biggest advantage of RM-IoT-Online (Wired Version) is its ability to provide stable, uninterrupted data transmission.

Compared to wireless solutions like Bluetooth, WiFi, or LoRa, a wired connection offers superior data transfer rates, particularly in scenarios requiring real-time, high-volume data transmission and long-term monitoring. This ensures a more reliable user experience while eliminating the complexities of wireless network configurations.

Feature Description

Integrated Equipment Inspection Data for IoT Dashboard Management

Managing multiple monitoring systems within a facility? RM-IoT-Online Rotor Health Monitoring System (Wired Version) allows users to access raw data, which can be consolidated into an IoT dashboard or integrated with third-party management systems for centralized control.

This feature enables real-time equipment status assessment, reduces troubleshooting time, and enhances overall efficiency. By integrating database-driven real-time monitoring, it provides users with the necessary insights to implement predictive maintenance strategies effectively.

Feature Description

AI-Based Degradation Prediction for Early Maintenance and Inventory Planning

RM-IoT-Online Rotor Health Monitoring System (Wired Version) features an AI-based degradation prediction model that integrates RULE BASE management principles and residual life prediction.

Users can define their desired prediction range, such as weekly or monthly forecasts. The system presents trends in graphical format with color-coded indicators—green, yellow, orange, and red—to help users proactively plan budgets and allocate maintenance resources efficiently.

Critical Equipment

Stable Monitoring

During critical production processes, unexpected failure of key rotor motors can result in irreversible losses of products or semi-finished goods. Installing the RM-IoT-Online Rotor Health Monitoring System (Wired Version) ensures seamless motor operation on the production line.

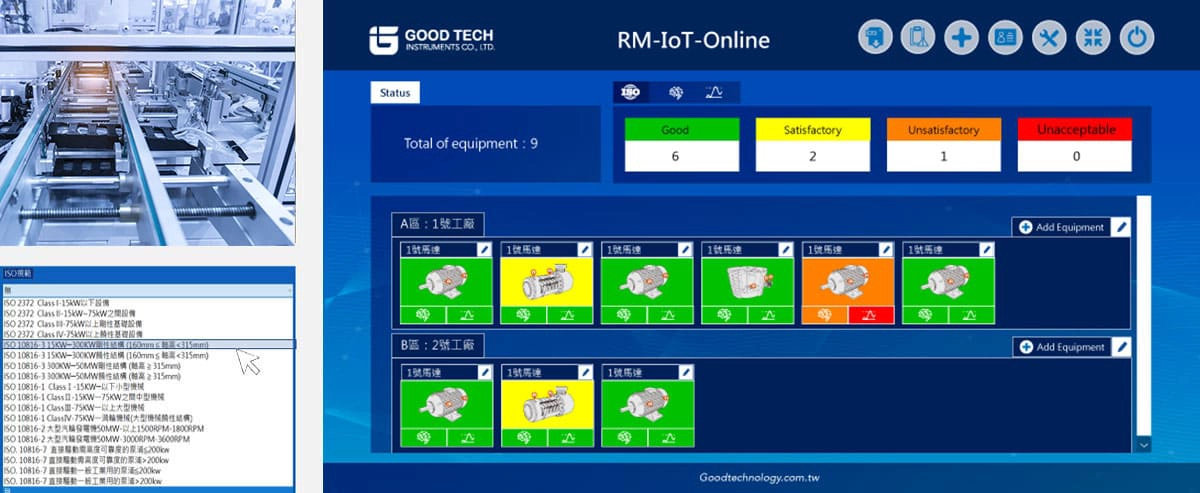

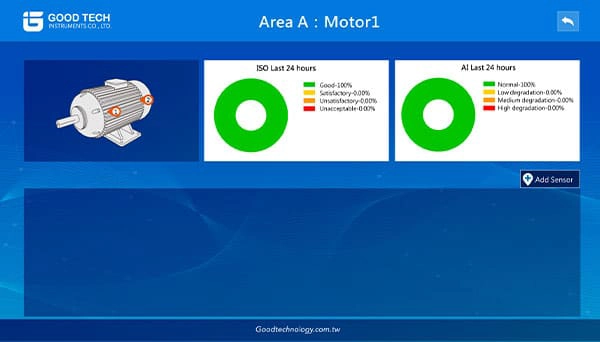

UI Functional Interface

Rotor Quality Standard Management

Software Feature Introduction: The Rotor Quality Standard Management System is built with ISO 10816 / 20816 / 2372 standards, applicable to various rotating machinery in industries ranging from semiconductors to transportation (motors, compressors, pumps, etc.). Users do not need to memorize standard charts; they only need to apply the corresponding standard based on motor output. The software differentiates equipment status using signal colors: Green - Excellent, Yellow - Normal, Orange - Warning, and Red - Danger, allowing users to have a clear overview of the entire facility's equipment status.

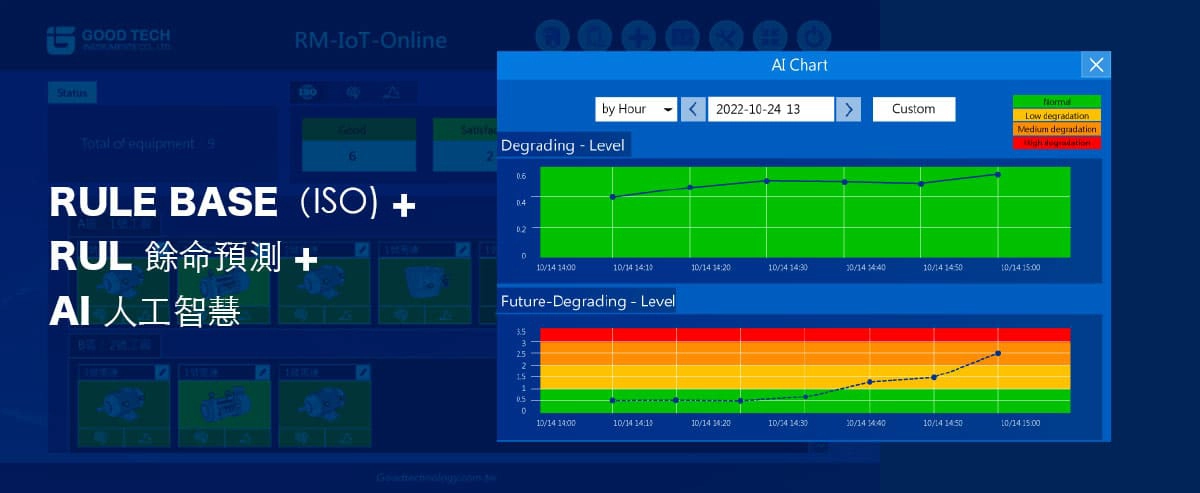

UI Functional Interface

AI Predicted Decline Trend

Software Feature Introduction: AI Predicted Decline Trend

AI prediction refers to the software's ability to automatically retrain its built-in monitoring models over specific time periods. As data accumulates, the AI system continuously optimizes itself within the preset time intervals.

The RM-IOT AI integrates traditional ISO 10816/20816 management principles with Remaining Useful Life (RUL) predictions.

The data cleansing and classification processes are fully automated, meaning users only need to input the specifications of their rotating equipment and the desired prediction time to get started.

UI Functional Interface

User-Defined Standards & Manual Experience Management

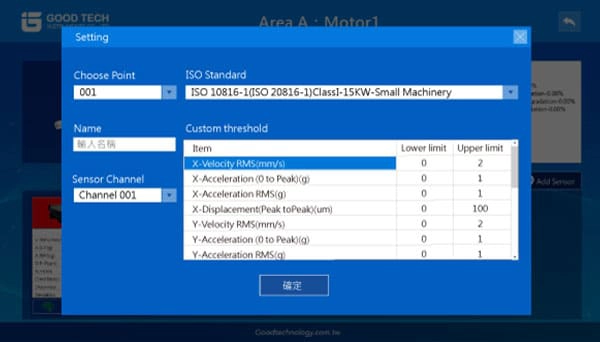

Software Feature Introduction: Custom Monitoring Alarm Threshold

The integrated sensor uses a three-axis MEMS vibration accelerometer, capable of collecting over 20 different monitoring parameters, including temperature, acceleration, velocity, displacement, and more.

When the ISO standards no longer meet specific user requirements, users can manually define threshold values or set limits based on parameters provided by equipment manufacturers.

If a data point exceeds the configured threshold, it will be highlighted in red as an alert. The system displays green for normal conditions and red for warning alerts.

This feature effectively helps users implement tiered equipment management and enables more precise monitoring of device conditions.

Application Targets

Applicable to Various Rotating Equipment Across Industries

Application Fields:

Semiconductor Industry: Stepper motors, cleanroom-specific drive motors.

Petrochemical Plants: Explosion-proof motors, high-temperature-resistant motors.

Food Industry: Drive motors, waterproof and dustproof drive motors.

Pharmaceutical Industry: Drive motors, drive systems.

Pulp & Paper Industry: High-torque motors, paper feeding systems, etc.

Panel Industry: High-precision positioning motors, high-speed motors.

LED Industry: High-brightness and uniformity motors, high-efficiency and low-energy motors.

Power Plants: High-power drive motors, high-durability and harsh-environment-resistant motors.

Manufacturing Industry: Multi-axis control systems, high-speed drive motors.

Setup Process

Easy Setup & Start Monitoring

1. Add New Area & Equipment

2. Define Monitoring Devices & Points

3. Select Applicable ISO Standards & Custom Thresholds

4. Instantly Receive Equipment Status Results

System Architecture

Rotor Equipment & System Framework

Support

Other Rotor Equipment Related Topics