Monitor Environmental Temperature, Humidity, and Particles

Why is it needed?

Beware! Defects in the Process Caused by Environmental Factors!

In certain precision manufacturing processes, environmental factors such as air temperature, humidity, and particle concentration can significantly impact product quality.

For example, in semiconductor manufacturing, airborne particles adhering to wafers can interfere with electronic components.

Rapid temperature fluctuations may cause uneven thermal expansion in equipment, affecting dimensional stability or causing component detachment.

High humidity levels can lead to condensation on wafer surfaces, affecting photomask precision or causing oxidation layer changes, ultimately impacting chip performance.

The Environmental Factor IoT is primarily used to monitor various environmental parameters, preventing defects in the manufacturing process or equipment failures caused by extreme environmental conditions.

Temperature

Humidity

Particle

Application Description

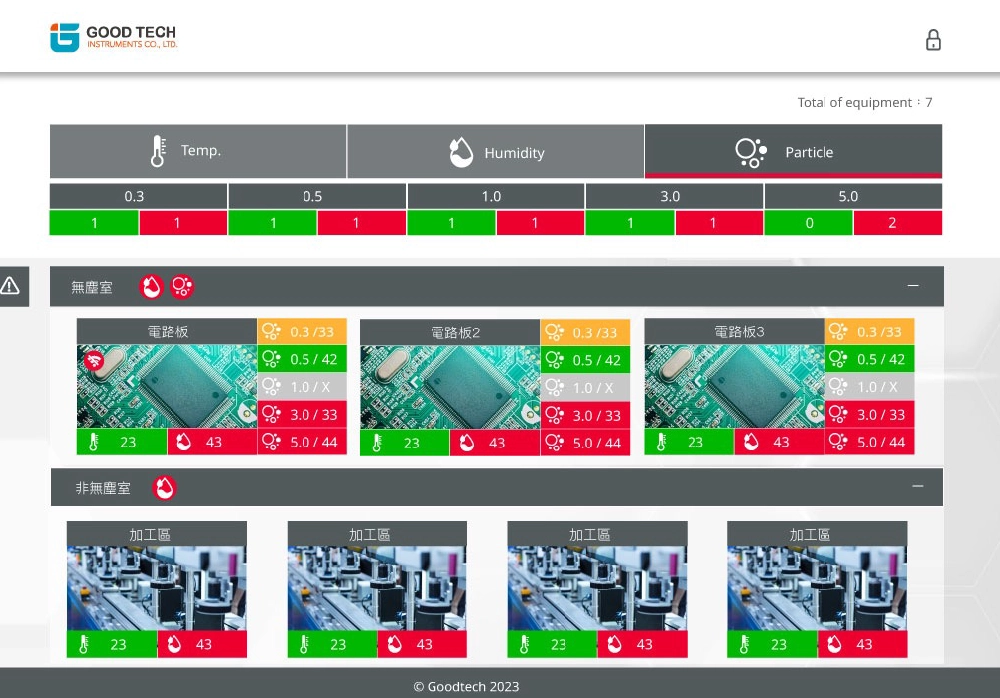

Envir IoT – Specialized for Monitoring Environmental Factors

Temperature Monitoring: Accurate to two decimal places, with sensor-dependent ranges of 0~50°C / 0~100°C / -50~50°C.

Humidity Monitoring: Accurate to two decimal places, with ±2% RH precision, ranging from 0% to 100% RH.

Particle Monitoring: Detects multiple particle sizes, including PM 0.3, PM 0.5, PM 1.0, PM 3.0, and PM 5.0.

Key Features:

1. Edge node directly processes and transmits physical data (no need to send data back to the system for processing).

2. Uninterrupted operation design (dual-layer protection against disconnection).

3. Disconnection alerts and warnings.

4. Flexible expansion for additional monitoring points.

5. Supports multiple signal types: 0-5V, 0-10V, 4-20mA, Modbus RTU, Modbus TCP, I²C, RS485…

Feature Description

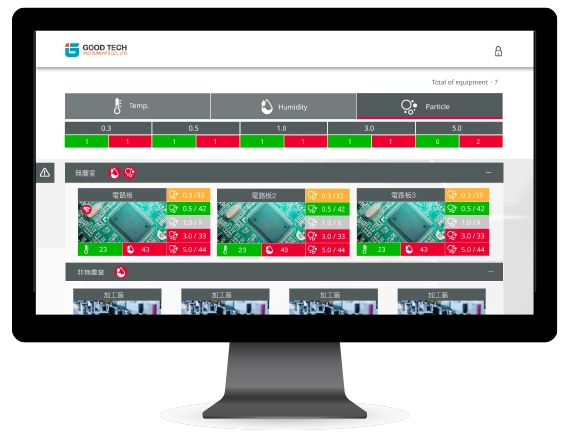

Real-Time Monitoring – Clear at a Glance

Envir-IoT Environmental Factor IoT is designed for long-term monitoring of temperature, humidity, and particles across various industries. The system categorizes all data statuses using indicator lights and displays them on the main interface: Green indicates normal conditions, Yellow signals a warning (first threshold), Red signifies an abnormal state (second threshold), and Gray means monitoring is not in progress. Users can quickly switch between tabs to check the current status and quality of environmental conditions.

Normal All values are within the normal range.

Warning Investigation or maintenance is recommended.

Abnormal Abnormal values detected, which may lead to process defects.

Feature Description

Up to Two Years of Data Logging

Still wasting time compiling data reports?

Monitoring environmental factors requires long-term data collection for trend analysis, traceability, and auditing.

Now, compiling and managing this data no longer requires extensive effort.

Envir-IoT Environmental Factor IoT supports long-term data storage, with built-in memory capable of saving up to two years of records.

The system automatically generates daily, weekly, and monthly trend graphs, making quality management and statistical analysis more efficient.

Feature Description

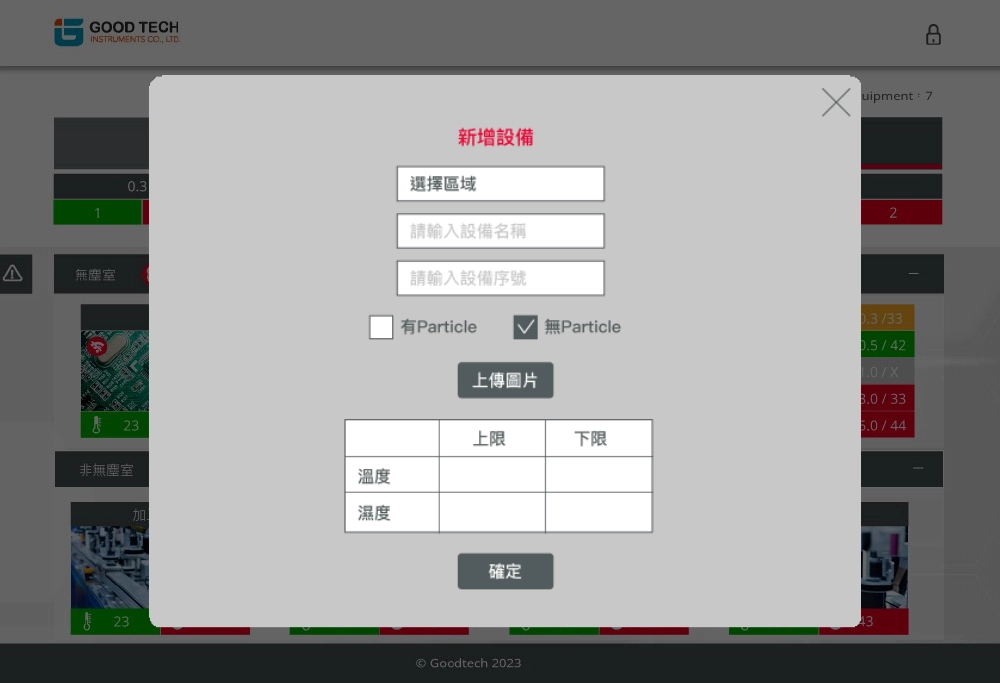

Dual Customizable Thresholds for Each Parameter

Users can set upper and lower threshold limits for temperature and humidity conditions.

If environmental parameters exceed the predefined range, the system will immediately send an alert via email, ensuring a swift response.

Additionally, Envir-IoT Environmental Factor IoT features a dual-threshold system.

The first threshold triggers an alert, allowing users to begin planning or early troubleshooting, effectively preventing critical red-alert anomalies.

Application Scope

Suitable for Precision Manufacturing Processes

Semiconductor Manufacturing:

Manufacturing processes require highly precise control of temperature, humidity, and particle concentration. Even minor fluctuations can lead to product defects.

Real-time monitoring and rapid response are essential to prevent contamination or environmental changes from affecting product quality.

Pharmaceutical Industry:

Must comply with strict regulations such as GMP, ensuring every stage of the manufacturing process takes place in a controlled environment.

Particle and microbial contamination can directly impact the quality and safety of pharmaceuticals.

Biotechnology:

Cell cultures and biological experiments are highly sensitive to environmental conditions, and any fluctuations may affect experimental results.

A sterile environment must be maintained throughout the experiment to prevent microbial and particle contamination.

Precision Machinery Manufacturing:

Airborne particles can affect machining accuracy and surface quality, increasing defect rates.

Additionally, environmental dust can accelerate equipment wear and shorten its lifespan.

Support

Other IoT-Related Topics