Prevent Equipment Failures Caused by Oil Degradation

Why is it necessary?

Poor Hydraulic Oil Quality?

Many hydraulic system failures are caused by contaminated or unclean oil, and even new equipment may contain pollutants.

Poor hydraulic oil quality can lead to unstable machinery operation, reduced transmission efficiency, increased failure rates, and higher energy consumption. The primary causes of oil degradation are poor cleanliness or contamination, which accelerates wear on hydraulic cylinders and pumps, affecting load efficiency and equipment lifespan. Maintaining good oil cleanliness can prevent 80%–85% of hydraulic system failures, ensuring equipment reliability and stable production line operations.

External Contamination

Internal Contamination

Oxidation Reaction

Thermal Decomposition

Condensation Phenomenon

Seal Failure

Why is it necessary?

How to detect changes in lubrication oil?

Conductivity:

High conductivity may indicate contamination in the oil, such as water or metal ions. When ions and polar molecules move more freely within the oil, oxidation and degradation accelerate, affecting oil quality. Therefore, pure oil has an extremely low actual conductivity, and by using high-precision conductivity measurement, we can detect changes in oil properties.

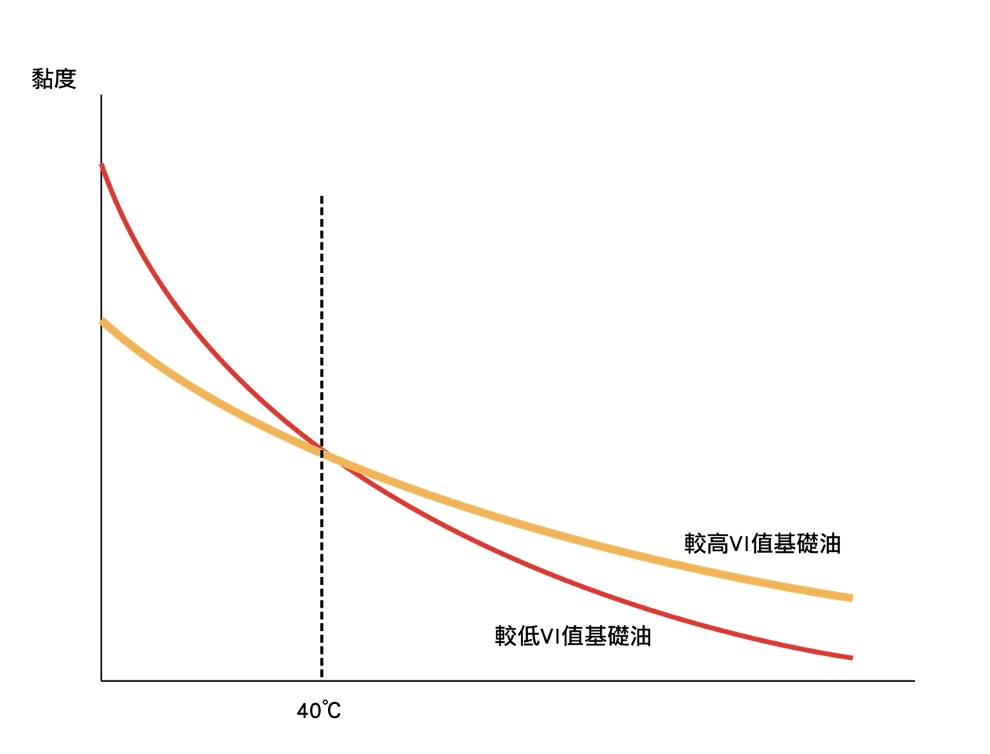

Temperature:

When the temperature rises, oil viscosity decreases. If it is too low, lubrication performance is affected, leading to excessive wear on mechanical components. Conversely, excessively high temperatures increase operational resistance and energy consumption. High temperatures may also cause the oil to form gel-like substances or deposits, affecting its cleanliness.

Feature Description

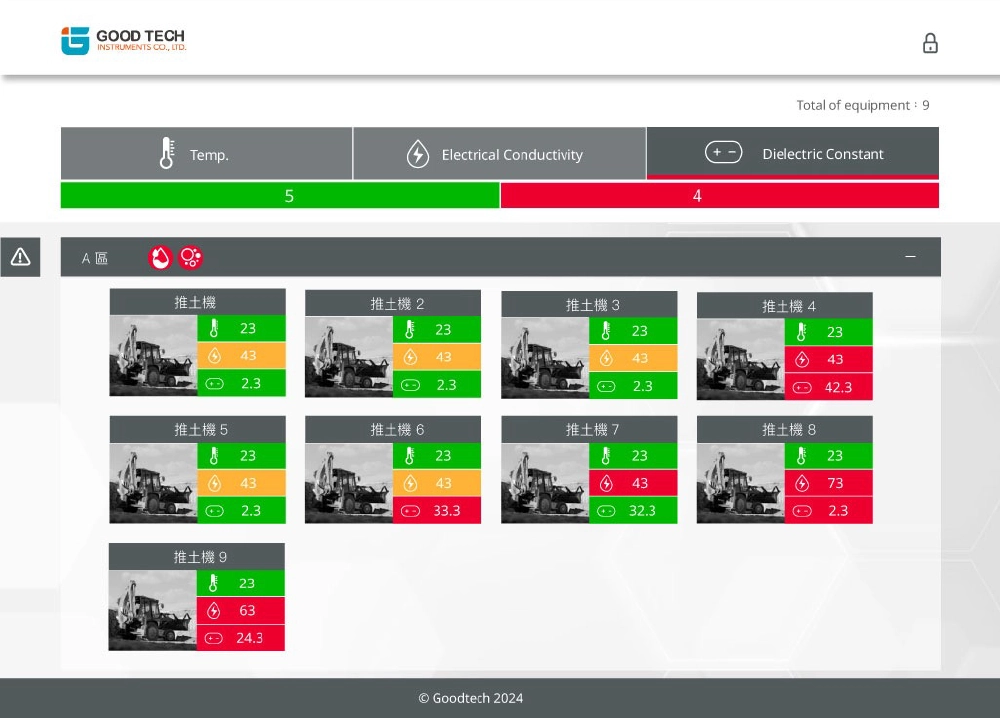

Real-time Monitoring for Clear Status Overview

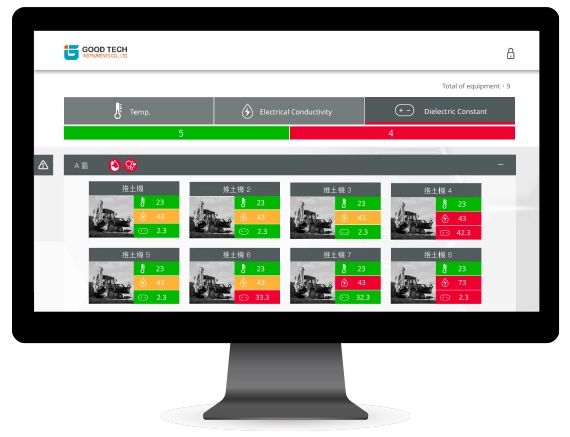

Oil-IoT Rotating Machinery Grease Condition Monitoring IoT is designed for long-term monitoring of grease condition, including temperature, conductivity, and dielectric constant. The unit of measurement for conductivity is pS/m, which can indicate the presence of synthetic compounds formed after grease molecule breakdown, micro-particles, and any depletion of additives. By combining temperature and dielectric constant data, changes in grease condition can be clearly identified.

The system categorizes all data states using signal lights and displays them in a unified main screen. A green light represents normal status, an orange light indicates a warning (first threshold), and a red light signifies an abnormal condition (second threshold). Users can quickly switch tabs to view the current status and quality.

Normal All values are within the normal range.

Warning Inspection or maintenance is recommended.

Abnormal Abnormal values detected, which may lead to process defects.

Offline Device or sensor is currently offline.

Feature Description

Up to Two Years of Data Recording

Still wasting time compiling data reports?

Various grease data require long-term collection to observe changes, along with detailed data records and reports for traceability and audits. Now, organizing these data no longer needs to be time-consuming. Oil-IoT Rotating Machinery Grease Condition Monitoring IoT supports long-term data recording with built-in storage capable of saving up to two years of data. It can automatically generate daily, weekly, and monthly trend charts, making quality management and statistical analysis more convenient.

Feature Description

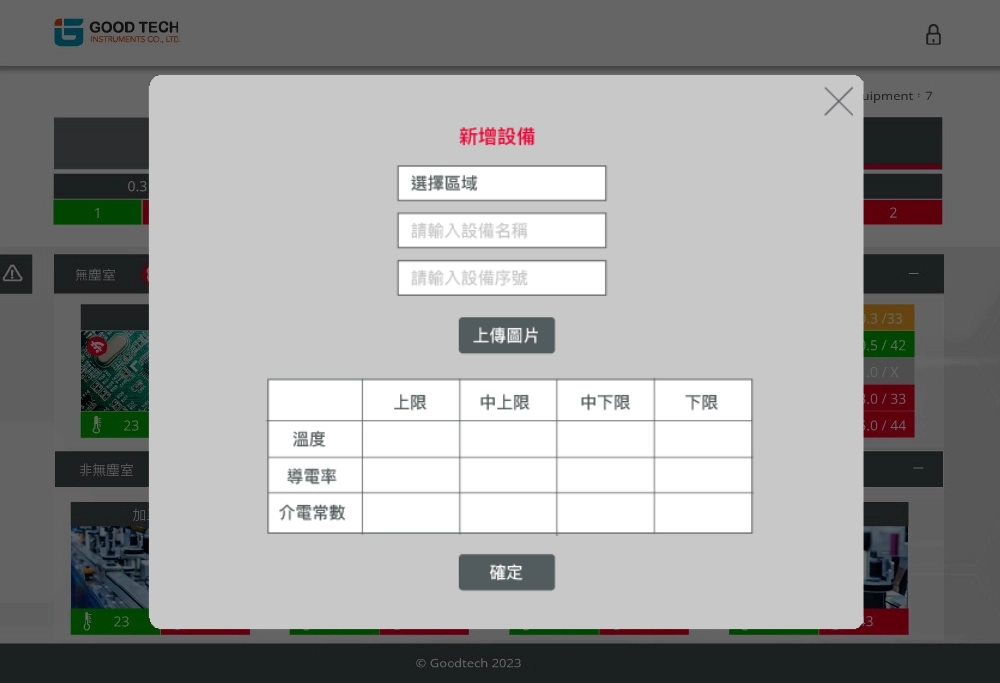

Dual Custom Thresholds for Each Parameter

Users can freely set upper and lower threshold values for temperature and humidity conditions. If environmental parameters exceed the set range, the system will immediately send an alert notification via email to ensure a quick response.

Additionally, Oil-IoT Rotating Machinery Grease Condition Monitoring IoT features a dual-threshold function. By setting the first threshold, the system will issue a warning, allowing users to start planning or conduct early inspections, effectively preventing the occurrence of a red-light abnormality.

Application Scope

The Condition of Oil Affects Equipment Operation

Applicable to ships, heavy machinery, offshore wind turbines, mining, automotive test benches, rotor wear detection, oil degradation monitoring, wind turbine gearboxes, etc.

1. Hydraulic Machinery: Excavators, loaders, bulldozers, etc.

2. Industrial Machine Tools: Press machines, CNC machine tools, etc.

3. Lifting Equipment: Cranes, forklifts, etc.

4. Metallurgical Equipment: Continuous casting machines, rolling mills, etc.

5. Construction Equipment: Concrete pump trucks

6. Agricultural Machinery: Tractors, harvesters, etc.

7. Wind Power Equipment: Wind turbines

8. Marine Equipment: Ship hydraulic systems, submersible pumps, etc.

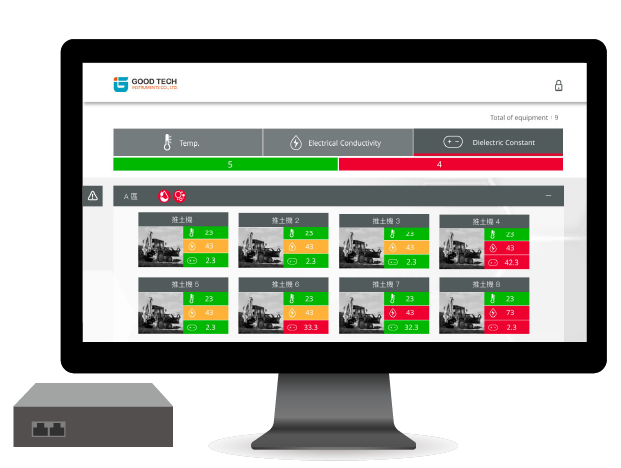

Architecture Overview

Unified IoT Monitoring Display for Entire Factory

Support

Other IoT-related Topics