Even the slightest fluctuation can lead to product defects

Why is it needed?

Why do wafer alignment machines need particle monitoring?

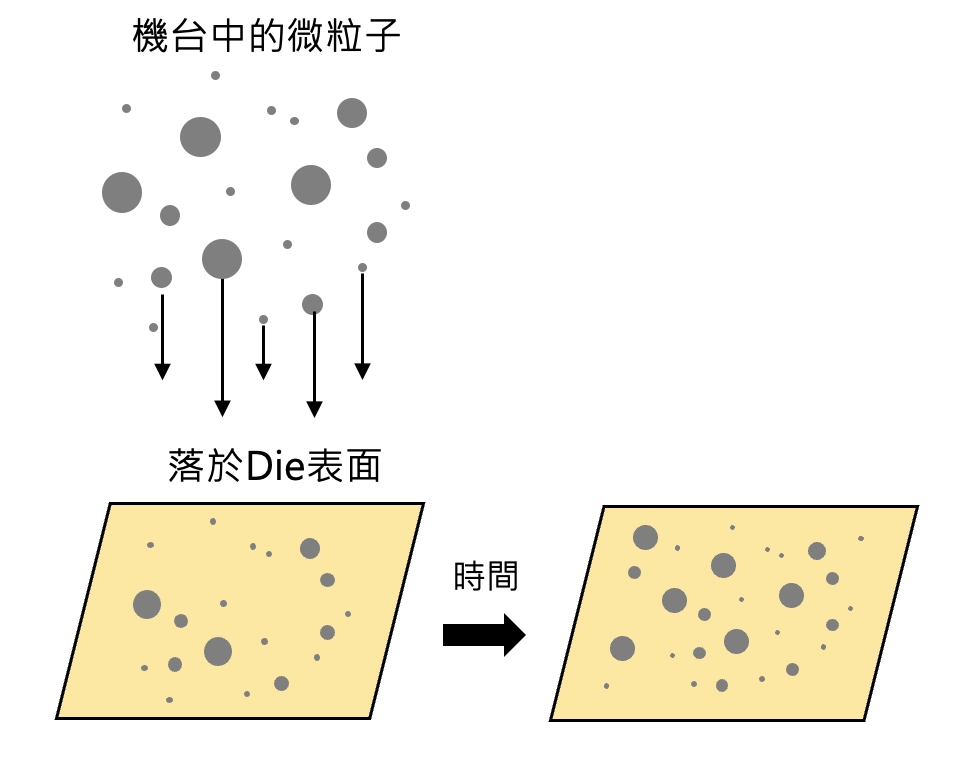

Excessive particle concentration inside wafer alignment machines can cause various issues, including reduced product quality, equipment malfunctions, electrostatic problems, and environmental safety risks.

Particles adhering to workpieces or material surfaces can lead to defects such as scratches, foreign objects, or uneven coatings, which in turn affect product performance. They may also enter sensitive machine components, such as optical elements or sensors, causing measurement errors or equipment damage.

Additionally, electrostatic effects can accelerate particle accumulation, creating a vicious cycle and potentially leading to electrostatic discharge (ESD) that damages components.

Why is it needed?

Excessive particle concentration in machines leads to process defects!

In the CoWos packaging process, fine dust particles adhering to the chip can interfere with electronic components, reduce thermal conductivity efficiency, and severely impact product quality.

Rapid temperature changes may cause uneven thermal expansion in the equipment, affecting dimensional stability or leading to component detachment.

Over time, the number of particles accumulates and increases

High humidity levels can lead to moisture condensation on the wafer surface, causing oxidation layer changes on the die and impacting chip performance.

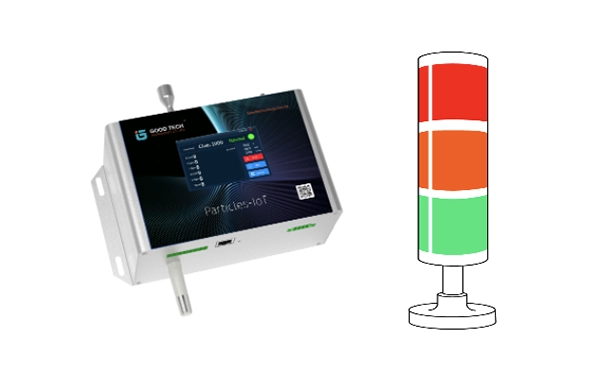

Particles-IoT Particle Monitoring IoT is designed to manage the concentration of particles inside loading machines, preventing excessive particle accumulation from causing process defects or equipment failures.

Feature Description

Designed specifically for monitoring environmental factors inside packaging machines

Particles-IoT Particle Monitoring IoT Key Features:

1. Smart particle algorithm for accurate measurement under different atmospheric conditions.

2. PID sampling control to maintain a constant sampling flow rate.

3. Continuous operation design with dual protection against disconnection.

4. Disconnection and warning alerts.

5. Flexible expansion of monitoring points.

6. Supports standard source coefficient calibration.

7. Industrial-grade laser light source for high reliability.

8. Real-time display of particle size distribution and classification levels.

Feature Description

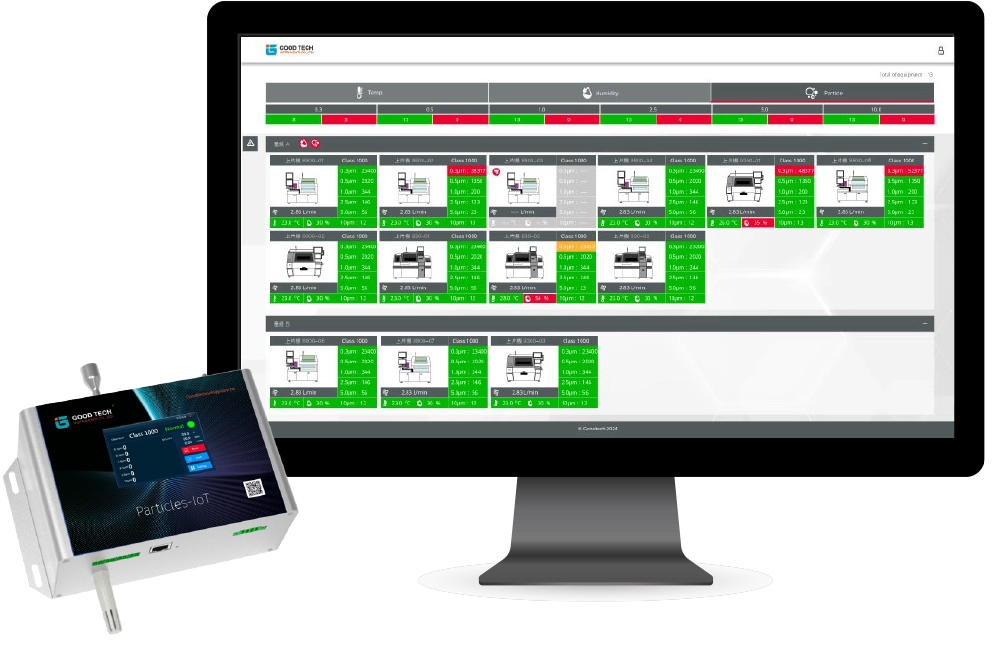

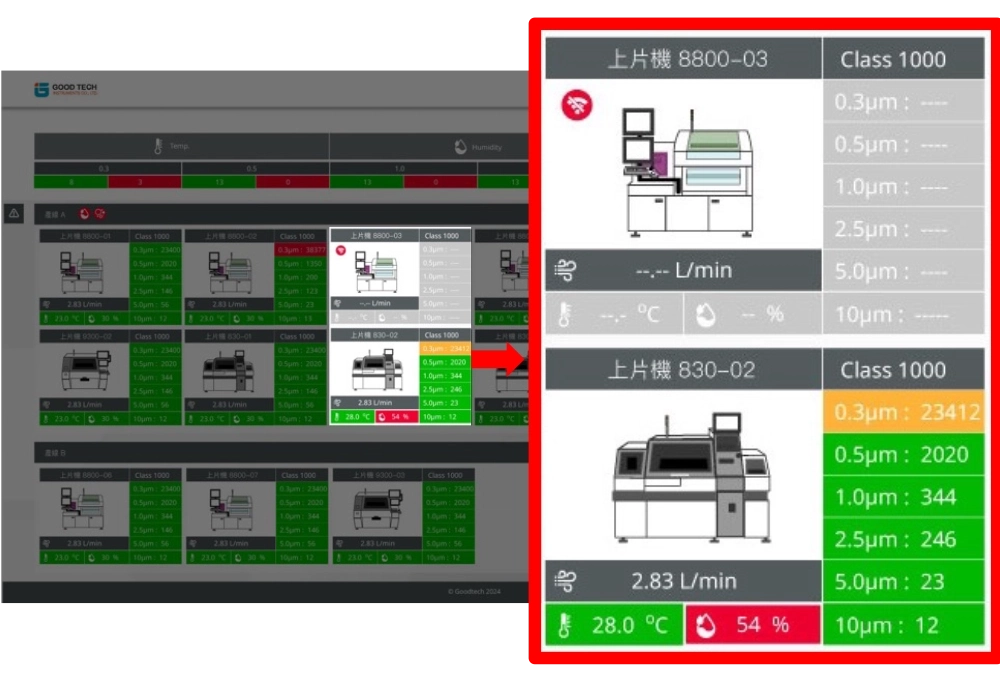

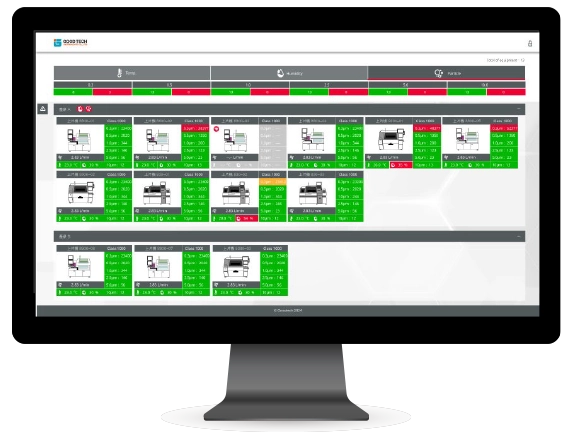

Real-time monitoring for instant status visibility

Particles-IoT Particle Monitoring IoT provides long-term monitoring of temperature, humidity, and particle concentration inside wafer loading machines. The system categorizes all data using indicator lights and displays them on the main screen in a unified manner. Green indicates "Normal," Orange indicates "Warning (first threshold)," Red indicates "Abnormal (second threshold)," and Gray indicates "Monitoring not executed." Users can switch tabs to quickly check the current status and quality.

Normal All values are within the normal range.

Warning Recommended to schedule an inspection or cleaning.

Abnormal Abnormal values may lead to process defects.

Offline Device or sensor is in a disconnected state.

Feature Description

Up to Two Years of Data Storage

Are you wasting time compiling data reports?

Various environmental factors require long-term data collection to observe trends, as well as detailed records and reports for tracking and auditing.

However, compiling this data no longer needs to be time-consuming. Particles-IoT Particle Monitoring IoT supports long-term data storage,

with built-in memory capable of storing up to two years of data. It can automatically generate daily, weekly, and monthly trend charts,

making quality management and statistical analysis more efficient.

Feature Description

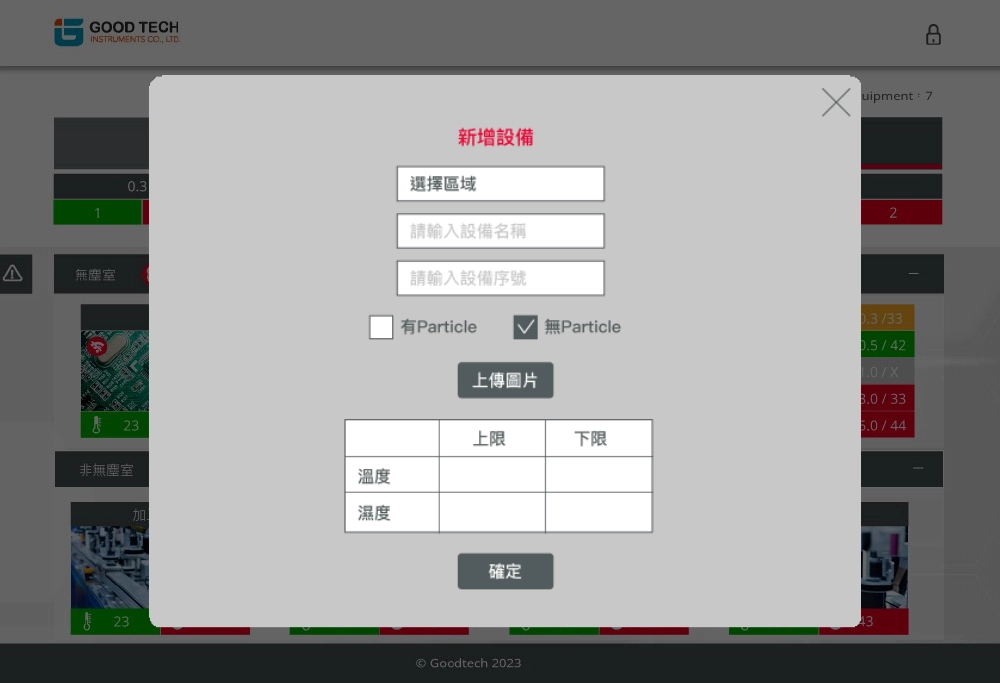

Dual Customizable Thresholds for Each Parameter

Users can freely set upper and lower threshold values for temperature and humidity conditions.

If environmental parameters exceed the preset range, the system will instantly send an alert notification via email,

ensuring a quick response.

Additionally, Particles-IoT Particle Monitoring IoT features a dual-threshold function.

When the first threshold is triggered, the system issues a warning, allowing users to start planning or conduct early inspections,

thereby preventing the occurrence of a red light (critical alert).

Working Principle

Stable Flow Air Pump

Simultaneous Output of Six-Channel Particle Count

Working Principle

High-Reliability Industrial Laser for Precise Measurement

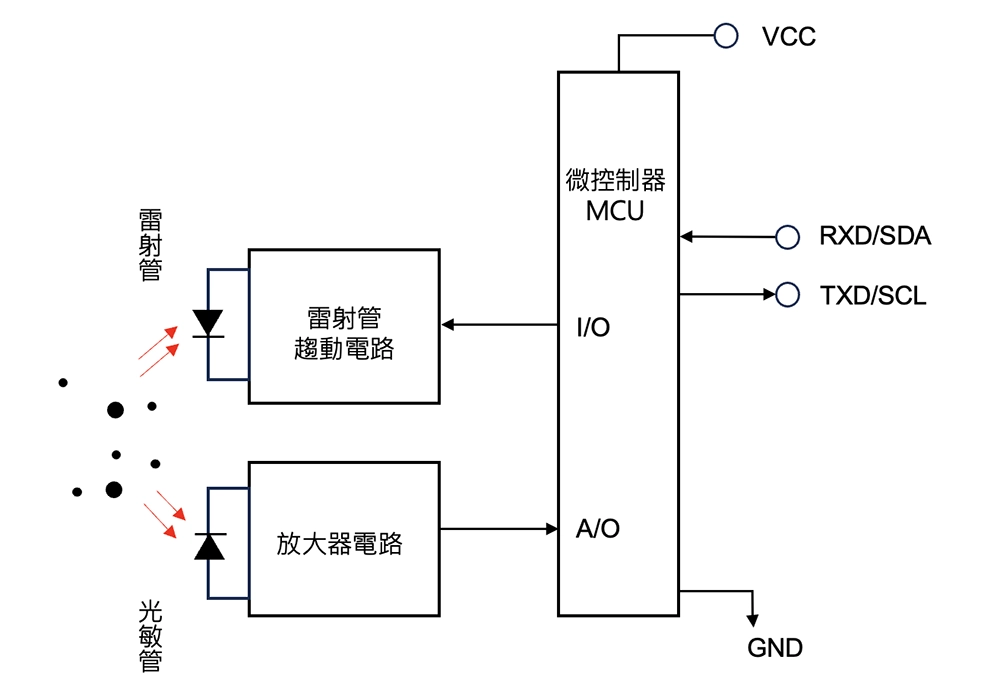

Utilizing a Semiconductor Laser Source for High-Precision Measurement

Air is sampled using a pump, and when airborne particles pass through the laser beam, light scattering occurs.

The scattered light is then converted into an electrical signal (pulse) by a photoelectric converter.

Larger particles produce larger peak values in the pulse signal. By analyzing these peak values and the number of pulses,

the system determines the number of particles of different sizes.

Application Scope

Suitable for Precision Product Manufacturing Processes

Applicable Fields Examples: Semiconductor industry, power battery manufacturing, biotechnology industry, laboratories, pharmaceuticals, food industry, LCD displays, precision machinery manufacturing, etc.

When particle concentration is too high, for example, in power battery production, if particles enter the active material layer of the battery, they may cause micro-short circuits, reducing battery capacity, or in extreme cases, lead to thermal runaway (such as fire or explosion).

Precision Requirements: High precision is required, as even the smallest fluctuations may result in product defects.

Regulatory Compliance: Must meet regulatory requirements to ensure that the manufacturing process takes place in a controlled environment.

Contamination Control: Prevents temperature, humidity, and particles from directly affecting quality and safety.

Product Quality: Impacts processing accuracy and surface quality, increasing defect rates.

Architecture

Standalone Monitoring, Real-time Alerts

Standalone Module:

Easy and quick installation, disconnection/warning (can be directly connected to an alarm system).

3.5-inch color display screen, real-time data display.

Can be directly connected to a buzzer alarm.

Architecture

Standalone Connection, Suitable for Inspection & Short-term Trend Analysis

Standalone Inspection:

By combining with a network cable and an industrial tablet, short-term data can be collected, allowing users to analyze trends through accumulated data.

The system retains the characteristics of an inspection tool, making it portable and usable on different machines.

Additionally, users can set dual threshold levels for more precise monitoring.

Architecture

Unified IoT Monitoring & Display for the Entire Factory

Support

Other IoT-Related Topics