Prevent Mechanical Damage Caused by Pump Powder Clogging

Why is it needed?

Long-Standing Challenges in Semiconductor Manufacturing

Semiconductor manufacturing involves essential processes such as etching, photolithography, diffusion, and thin-film deposition.

Ensuring the operational health of equipment in each of these processes is critical. For example, in the diffusion process,

"thermal oxidation" relies on the proper functioning of high-temperature oxidation furnaces. If vacuum levels are insufficient,

an entire batch of wafers inside the furnace could be compromised, leading to significant financial losses. However, preventing

furnace failures presents several challenges.

The oxidation furnace operates using vacuum pumps (Dry Pumps), which contain rotor motors and Roots pumps. Monitoring systems

provided by vacuum pump manufacturers typically track parameters such as pressure, flow rate, temperature, and current—but not vibration.

As a result, users lack the critical insights needed to detect early signs of failure.

Users have two key expectations for vacuum pumps: first, to identify failure precursors and avoid unplanned downtime;

second, to establish reliable benchmarks for extending the operational life of functional pumps, reducing maintenance costs.

Even when sending pumps for maintenance, users must ensure that serviced equipment meets operational specifications.

Traditionally, users have relied on current monitoring to assess mechanical health. However, current is a lagging indicator—by the

time an abnormal surge in current is detected, failure is imminent, making predictive maintenance ineffective.

Additionally, pump lifetime is often determined based on human experience and statistical analysis. Regardless of actual pump condition,

units are sent for maintenance once they reach a predetermined runtime, leading to unnecessary maintenance costs. Furthermore,

when returned from servicing, pumps are typically inspected using current readings alone, which is insufficient to guarantee the

effectiveness of outsourced maintenance, increasing the risk of premature aging within the expected lifetime.

Unable to Detect

Failure Symptoms

Prevent Unexpected

Downtime

Extend Working

Life of Equipment

Ensure Quality

of Serviced Equipment

Over-Reliance on

Human Expertise

Unnecessary Costs

for Servicing Equipment

Problem Solving

Expecting Accurate Lifetime Prediction and Reduced Maintenance Costs

Users often face challenges with Dry Pumps, such as premature aging before reaching their expected working hours (before scheduled maintenance),

powder clogging leading to mechanical damage or complete failure, and lubrication oil issues at the bearing end causing premature pump failure.

Operational Dry Pumps require extended scheduled maintenance to minimize costs. Users also need assurance that serviced equipment

meets required maintenance specifications.

To address these pain points, Gude Technology has developed specialized software and algorithms incorporating ISO 10816 rotor machinery vibration

quality assessment, Broad Band numerical management, and SOA (Spectrum Overall Value) management.

These features translate complex signals into intuitive health indicators, compensating for the limitations of traditional monitoring systems.

Even users without FFT (Fast Fourier Transform) spectrum analysis expertise can detect subtle anomalies through this solution.

Users can quickly assess whether their vacuum pumps are in "Excellent," "Normal," "Warning," or "Dangerous" condition.

The system also supports often-overlooked secondary variation management to accommodate short-term trend analysis.

Execution Goals

# Understand Equipment Quality to Prevent Unexpected Downtime

Monitor the health status of Dry Pumps and implement predictive maintenance strategies to prevent powder clogging,

lubrication oil issues (leakage or deterioration), mechanical failures, and pump shutdowns.

# Quickly Identify Root Causes and Resolve Abnormalities

With various Dry Pump models impacting production processes differently, timely problem diagnosis is crucial.

Immediate root cause identification and resolution prevent increased product defect rates and rising production costs.

# Reduce Maintenance Costs and Ensure Effective Servicing

Given the variety of Dry Pump models, users often rely on third-party servicing. However, it is difficult to verify

maintenance effectiveness post-service. By monitoring Dry Pump quality, unnecessary maintenance can be avoided,

ensuring maintenance occurs at the right time to optimize costs.

# Extend the Operational Life of Functional Equipment

In semiconductor manufacturing, Dry Pumps play a vital role. Many users, unaware of equipment condition,

send pumps for servicing at preset intervals, often replacing unnecessary components. Understanding equipment quality

enables smarter spending while preventing premature aging.

Problem Solving

Benefits of OLVMS®-DP!

Easy to Use

Monitor Equipment Quality

Precise Maintenance Instructions

Enhance Maintenance

Prevent Downtime Losses

Reduce Maintenance Costs

Feature Overview

Real-Time Monitoring to Prevent Downtime Risks

In industrial safety systems, Dry Pump failures pose immediate risks to both the environment and personnel.

In semiconductor manufacturing, vacuum system failures in Dry Pumps can lead to increased defective products

and contamination. The OLVMS®-DP Vacuum Pump Monitoring System enables users to track equipment status

in real-time and digitize predictive maintenance workflows.

Feature Overview

Instant Equipment Status Display and Classification

The OLVMS®-DP Vacuum Pump Monitoring System defines equipment conditions

based on ISO vibration standards, categorizing them into four levels: Excellent, Normal, Warning, and Dangerous,

displayed using color-coded indicators.

Users can also set custom thresholds. The system provides instant measurement results without the need for on-site inspections,

allowing for real-time issue detection and helping users establish internal equipment health management standards.

Feature Overview

Trend Charts and Smart Diagnostics

The OLVMS®-DP Vacuum Pump Monitoring System enables real-time monitoring and data collection.

It records historical data and equipment quality trends for rotor systems.

Maintenance teams can schedule servicing based on detected anomalies and analyze equipment health trends using the

interval selection feature. Integrated smart diagnostics provide preliminary failure cause analysis, helping users

quickly perform maintenance tasks.

Feature Overview

Lowering Technical Barriers for Easy Operation

The OLVMS®-DP Vacuum Pump Monitoring System is compatible with various rotor equipment models,

featuring built-in recommended measurement points for quick sensor setup.

The system includes preloaded ISO standards, eliminating the need for manual lookup—users simply select the

applicable standard to start monitoring. Additionally, Gude Technology leads the market by incorporating the

latest ISO 20816 standard, ensuring comprehensive motor and rotor component management.

Early Detection

of Failure Precursors

Dry pump equipment in the Sub-Fab plays a critical role in manufacturing processes and product quality. During equipment operation, the OLVMS®-DP Vacuum Pump Monitoring System helps users maintain production stability by detecting early failure indicators, preventing breakdowns and unexpected downtime.

UI Functional Display

Main System Interface

UI Functional Display

Trend Graphs and Alarm Notification Settings

The OLVMS®-DP Vacuum Pump Monitoring System enables real-time monitoring and data collection, recording measurement history and quality status for all defined rotor equipment measurement points. The system provides trend graphs for display, allowing maintenance personnel to plan servicing schedules and assess the health status of rotor equipment in real time.

UI Functional Display

Standard Configuration

The OLVMS®-DP Vacuum Pump Monitoring System includes recommended rotor ISO standards for various types of rotor equipment.

No manual reference is required—users simply select the corresponding equipment on the interface to obtain measurement results.

Simultaneous Monitoring of Three Standards:

ISO: Different motors have different vibration levels as part of a broad industry standard.

Broad Band: The baseline vibration threshold is set within ±25%; exceeding this range indicates potential issues.

SOA (Spectrum Over All): Vibration levels exceeding twice the baseline trigger a warning, and those exceeding six times indicate danger.

UI Functional Display

Intelligent Diagnosis

The OLVMS®-DP Vacuum Pump Monitoring System integrates intelligent diagnostics to provide preliminary failure causes, assisting users in performing maintenance efficiently.

Application Scope

Compatible with Various DRY PUMP Equipment

Primary Application Fields:

Semiconductor crystal growth plants, semiconductor manufacturing, panel manufacturing, Sub-Fab vacuum systems,

and various manufacturing facility vacuum systems.

Applicable Equipment:

Crystal Growth Furnace, LPCVD Furnace Tube, Ion Implanter, CVD Producer, PVD Sputter, Dry Etch, Slit Coater, etc.

The system prevents premature aging of Dry Pumps before reaching their expected working hours (before scheduled maintenance).

It also prevents powder clogging, which can lead to mechanical damage or total failure causing unexpected downtime.

Furthermore, it addresses lubrication issues at the bearing end (oil leakage or degradation),

ensuring extended operational life and optimized maintenance scheduling with data-driven cost reduction.

Users can also verify whether serviced equipment meets maintenance requirements,

ensuring the effectiveness of outsourced maintenance services.

Ion Implanter

Dry Etch

Slit Coater

CVD Producer

LPCVD Furnace Tube

Crystal Growth Furnace

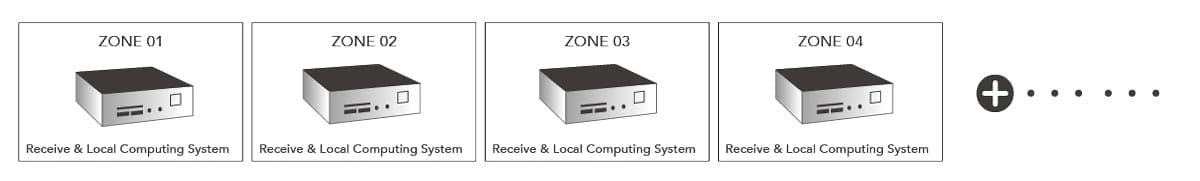

System Architecture

Vacuum Pump Monitoring System

Support

Other Rotor Equipment-Related Topics