Servo Axis and Suction Pressure Monitoring

Why is it needed?

Loader Motion Abnormalities?

A Crucial Link in the Process

In the die bonding process, the loader is responsible for separating individual dies from the wafer

and placing them onto the packaging substrate. This requires micron-level precision control and stability.

The loader’s motion axes operate under high-intensity continuous cycles. If motor operation becomes unstable or

fails, misalignment during wafer pickup can lead to defective products, increased scrap rates,

and production downtime.

Precise Control of Suction and Pressure

During the loader’s Pick & Place process, the suction nozzle relies on vacuum pressure to generate the necessary force

to move wafers or dies between locations. The level of vacuum pressure directly determines the nozzle’s gripping ability.

When the nozzle contacts the wafer surface, appropriate contact pressure must be applied to ensure secure handling.

Insufficient pressure may cause weak adhesion, leading to potential drop-offs, while excessive pressure can damage the

die, resulting in product defects and losses.

Why is it needed?

Does Pneumatic Cylinder Quality Affect Alignment?

Pneumatic Cylinder Malfunction Leads to Product Scrap!

In the die bonding process, the pressure applied by the pneumatic cylinder ensures

even distribution of solder and forms a secure connection at the weld points.

Various factors can cause pneumatic cylinder abnormalities, such as valve core blockage

due to oil contamination or valve wear, misalignment of the shaft preventing cylinder actuation,

or foreign object intrusion causing cylinder scoring.

When the pneumatic cylinder operates unstably, it can result in inaccurate die alignment,

affecting electrical connections and ultimately leading to product failure.

Feature Overview

Ensuring the Quality of Loader Moving Axes

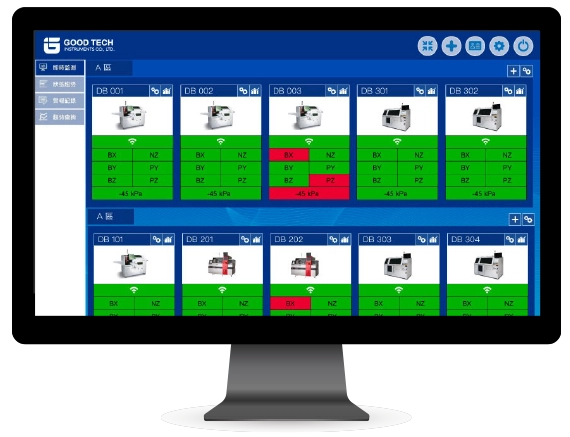

Red light indicates abnormal axis current signals

External clamp sensor for current measurement, no need for direct signal integration!

Start monitoring immediately, tracking X, Y, and Z motor current signals.

The motors driving the loader's moving axes power the Bond Head's movement.

When motors operate stably, the moving axes function smoothly. However, inadequate lubrication,

obstruction, or wear increases mechanical resistance, forcing the motor to draw more current

to maintain power output, which can result in excessive vibration.

Therefore, we use the DB-IoT Loader Quality Monitoring IoT to monitor changes in axis

current, enabling early detection of anomalies and ensuring stable loader operation.

Detect early anomalies by monitoring motion axis current signals!

Feature Overview

Increased Human-to-Machine Ratio, Enhancing Management Efficiency

The DB-IoT Loader Quality Monitoring IoT centralizes real-time status updates across all loaders.

Engineers and operators no longer need to stay beside the machines continuously.

Instead, they can monitor from a centralized control room and respond to alerts only when necessary,

freeing up valuable time for more strategic tasks.

Centralized monitoring with real-time alerts!

Feature Overview

Prioritizing Maintenance Scheduling

In manufacturing facilities, meeting customer orders and market demands is crucial.

Any unexpected downtime for maintenance could impact production plans and reduce output.

Maintenance scheduling should prioritize the most critical or urgent cases.

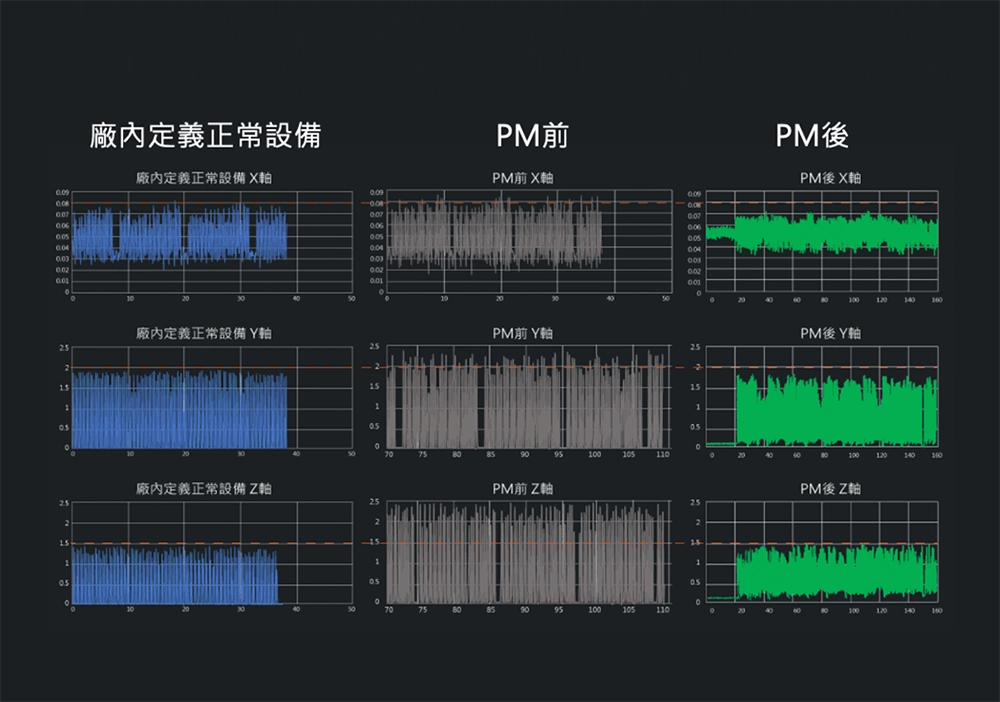

The DB-IoT Loader Quality Monitoring IoT displays machine status with traffic light indicators,

allowing users to plan maintenance accordingly. The system also provides trend graphs to compare

operational efficiency before and after machine servicing.

Provides predictive maintenance insights and post-maintenance comparison!

Feature Overview

Identifying Maintenance Locations

Loaders consist of complex mechanical components with highly interactive systems.

This complexity makes it difficult to pinpoint failure causes, prolonging maintenance times.

How can we quickly identify failure locations and reduce repair time?

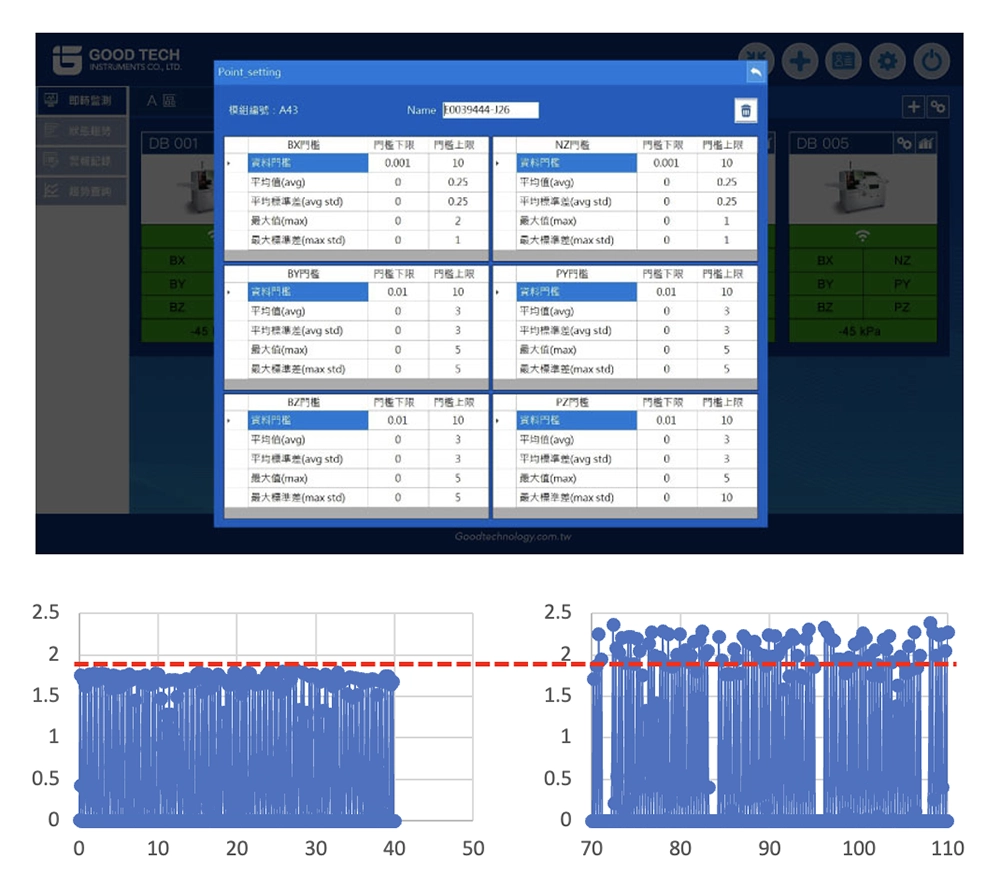

The DB-IoT Loader Quality Monitoring IoT allows users to define customized thresholds.

Each axis has an independent status indicator, helping to track current fluctuations and pinpoint

specific axis failures, reducing troubleshooting time.

Customizable thresholds with targeted axis diagnostics!

Application Scope

Die Alignment and Wafer Placement Process Monitoring

Support

Other Semiconductor-Related Solutions