Prevent Abnormal Vibrations from Causing Material Misalignment

Why is it needed?

Interruptions in the manufacturing process can lead to failure!

In the reflow process, the normal operation of the equipment is crucial for process stability and product quality. If the operation is unstable or abnormal vibrations occur, the molten solder may shift, leading to solder bridging or product misalignment.

Furthermore, any abnormalities in the process may result in interruptions during soldering, causing the entire batch to fail or requiring the soldering process to restart. Therefore, ensuring that each step runs smoothly and stably is essential.

Feature Description

Prevent Die Shift and Improve Yield!

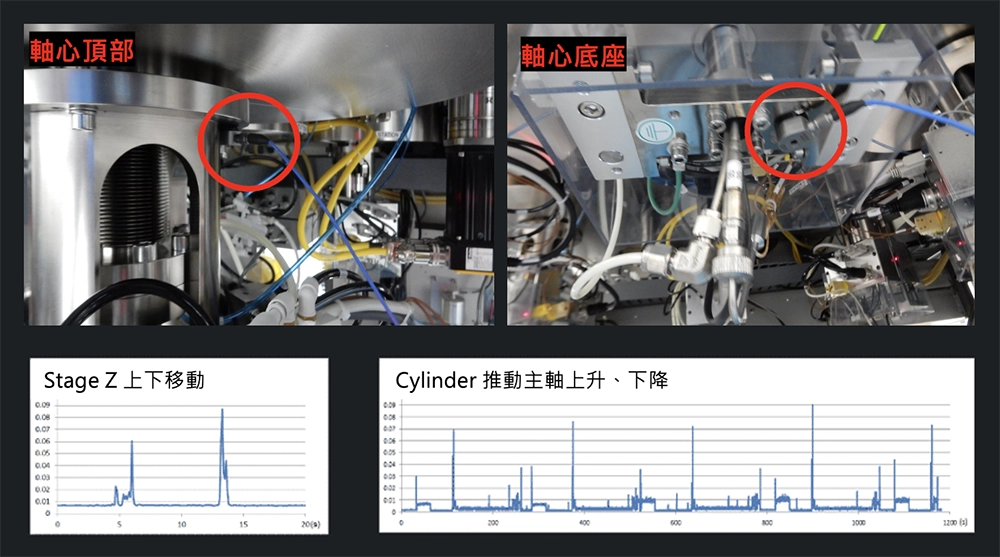

In the reflow process, heating causes the solder to melt and resolidify, ensuring a strong connection between the chip and the substrate. If the pneumatic cylinder or electric cylinder's movement is unstable while driving the heating plate up and down during reflow soldering, it may cause material misalignment in the soldering area.

By utilizing the VMS-M14 Dynamic Monitoring System, dynamic vibration characteristic values generated during the movement of the pneumatic cylinder or electric cylinder driving the heating plate up and down can be monitored. This prevents abnormal vibrations caused by aging or malfunctions of the mechanism, avoiding misalignment of materials and products.

Feature Description

Real-Time Status Display and Anomaly Prevention

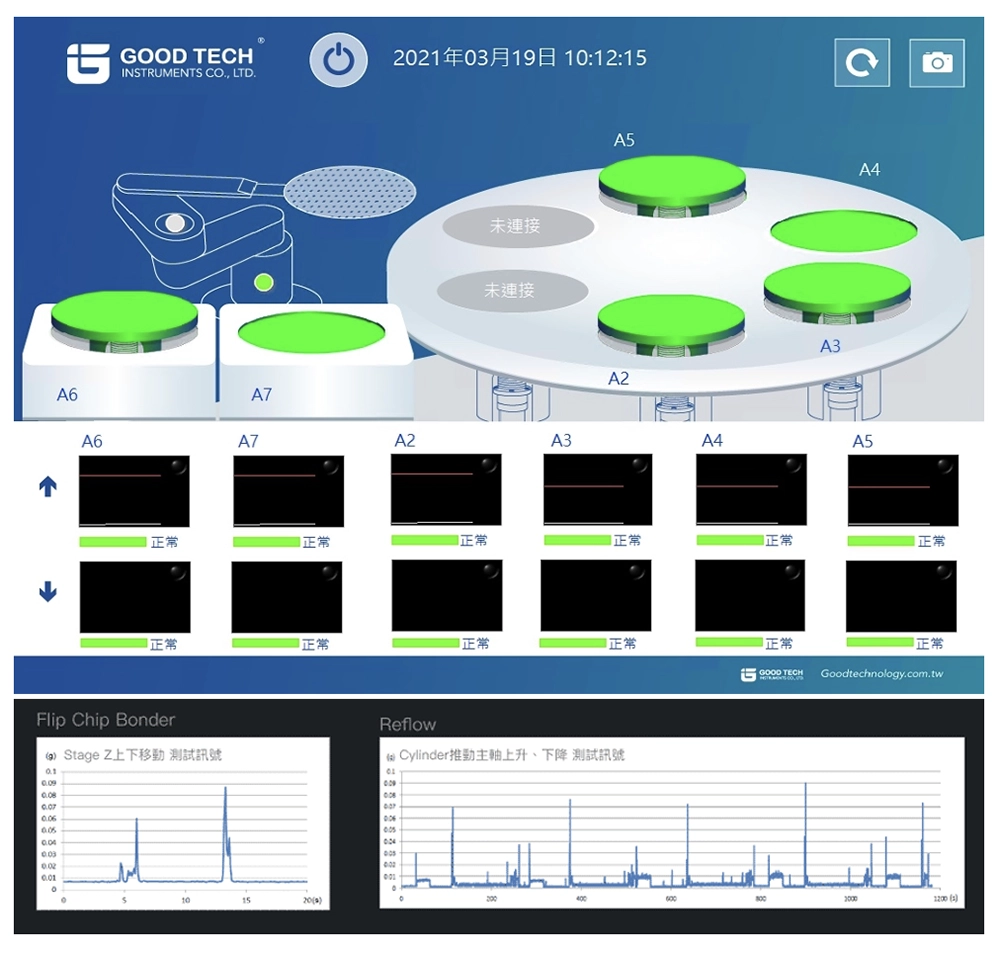

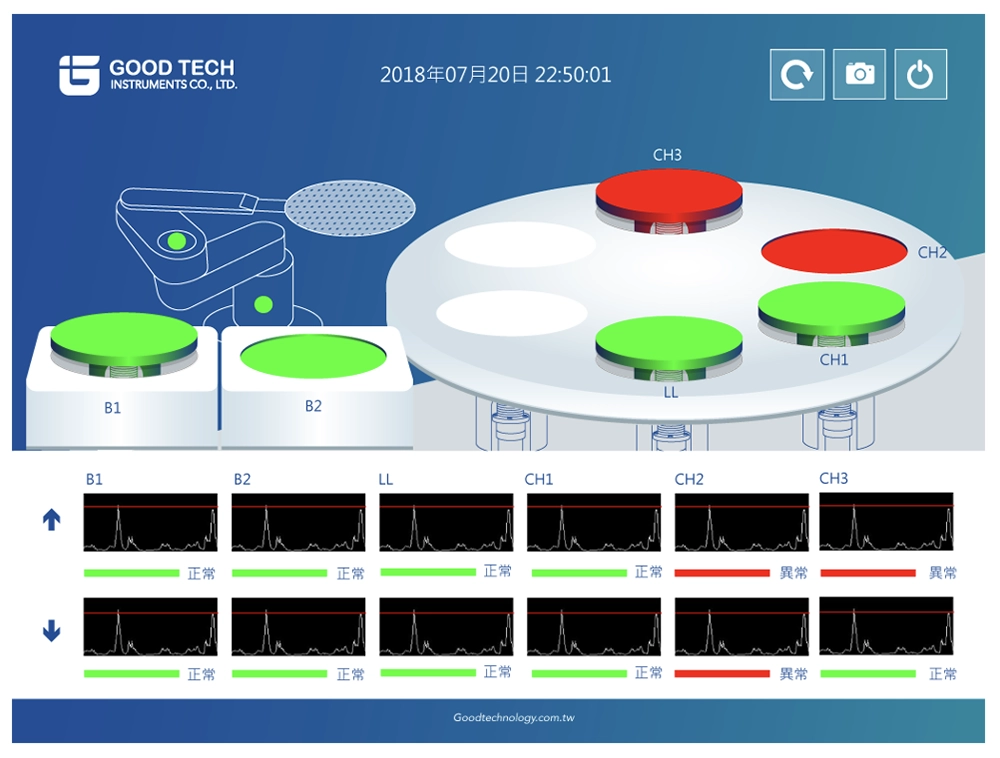

To determine when to intercept signals, a sensor is installed on the main shaft before the cylinder operation. The VMS-M14 Dynamic Monitoring System measures the vibration values generated during upward and downward movements.

The graphical characteristics are digitized to build a big data database. By defining threshold values, users can manage the cylinder's quality status in real time.

The main interface displays real-time status using a traffic light system (red/green), making it easy to monitor at a glance. If the vibration value exceeds the threshold, the machine immediately cuts off the signal to prevent wafer misalignment or breakage.

Red light indicates an anomaly, with a buzzer alerting users

Red light indicates an anomaly, with a buzzer alerting users

Feature Description

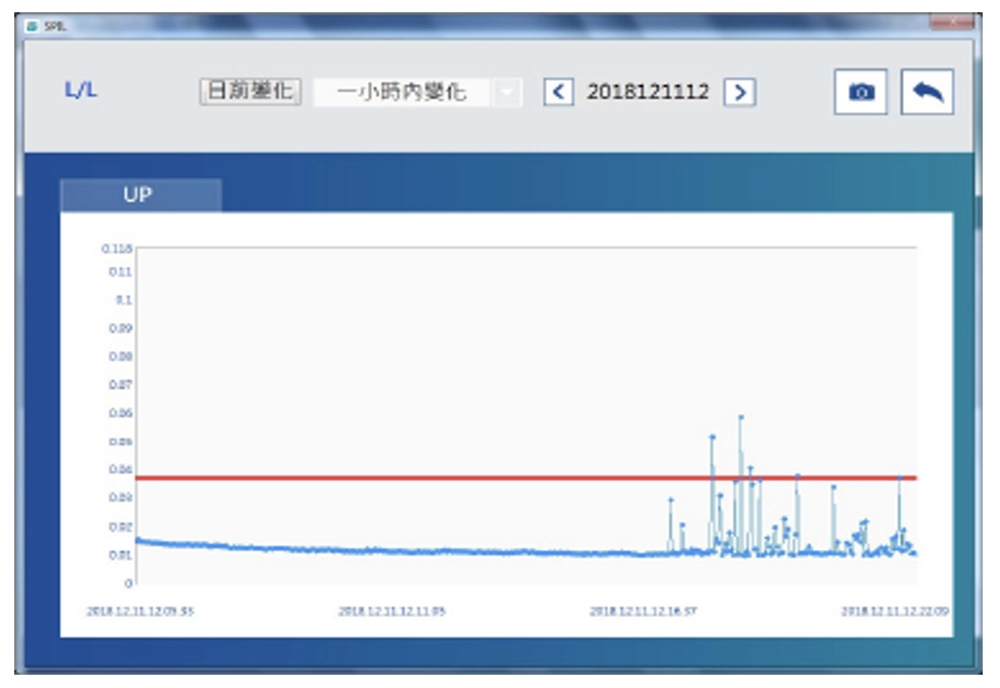

Trend Analysis for Predictive Maintenance and Process Stability

If the pneumatic cylinder deviates from its intended position, fails to reach its destination, or moves inconsistently, this may indicate mechanical failure or control system issues.

Example: Excessive speed fluctuations or abnormal acceleration/deceleration changes may suggest internal wear, insufficient lubrication, or air leakage.

Using the VMS-M14 Dynamic Monitoring System, quality trends can be quantified to assist in scheduling predictive maintenance.

By collecting long-term data, trend variations can be analyzed to identify the timing of anomalies, allowing for optimized predictive maintenance scheduling to ensure process stability and product quality.

Feature Description

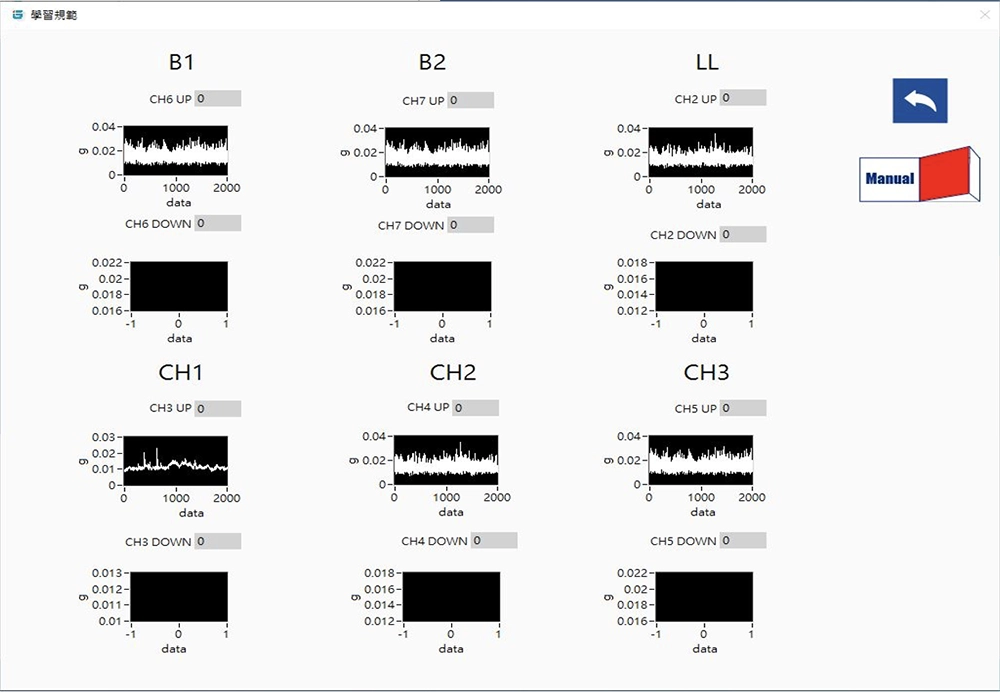

Fully Automated Learning and Monitoring Model Establishment

The VMS-M14 Dynamic Monitoring System uses a fully automated learning mode to record the highest vibration values during the learning period or allows manual input of standards.

By selecting the measurement area, users can access detailed trend analysis of each section. If the monitored dynamic vibration value exceeds the preset threshold, the system immediately triggers an alert. Additionally, users can analyze the trend charts to assess equipment conditions, providing a valuable reference for setting future predictive maintenance points.

Benefits

Effectively Preventing Defective Products

VMS-M14 Dynamic Monitoring System is an intelligent monitoring system specifically designed for Die Bonder and Reflow combination process machines in the 2.5D manufacturing process. During the Flip Chip Bonding stage, it monitors the die placement machine to ensure adhesive application and material bonding quality, preventing misalignment due to machine aging or component failure. In the Reflow stage, it monitors specific dynamic vibration values generated when the pneumatic cylinder or electric cylinder moves the heating plate up and down, ensuring that material bonding is not affected by structural aging or faults.

When the monitored dynamic vibration values exceed the preset threshold, the system instantly triggers an alert. Additionally, users can analyze trend charts to assess equipment conditions and establish predictive maintenance reference points.

Quick to Use

Equipment Control

Precise Maintenance

Improved Efficiency

Reduced Scrap Rate

Lower Costs

Performance

Real-Time Monitoring of Pneumatic Cylinders (Electric Cylinders) Dynamic Signals

Support

Other Semiconductor-Related Fields